Work, Power and Energy

INTRODUCTION

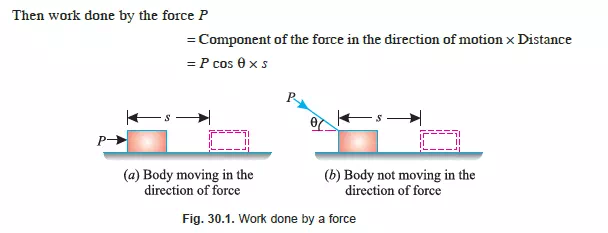

Whenever a force acts on a body, and the body undergoes some displacement, then work is said to be done. e.g., if a force P, acting on a body, causes it to move through a distance s as shown

in Fig. 30·1 (a). Then work done by the force P

= Force × Distance

= P × s

Sometimes, the force P does not act in the direction of motion of the body, or in other words, the body does not move in the direction of the force as shown in Fig. 30·1 (b).

UNITS OF WORK

We have already discussed that the work is the product of force and distance, through which the body moves due to action of the force. Thus the units of work depend upon the units of

the force and distance. The units of work (or work done) are :

1. One N-m. It is the work done by a force of 1 N, when it displaces the body through 1 m. It is called joule (briefly written as J), Mathematically.

1 joule = 1 N-m

2. One kN-m. It is the work done by a force of 1 kN, when it displaces the body through 1 m. It is also called kilojoule (briefly written as kJ). Mathematically.

1 kilo-joule = 1 kN-m

Note. Sometimes, the force stretches or compresses a spring or penetrates into a body. In such a case, the average force is taken as half of the force for the purpose of calculating the work done.

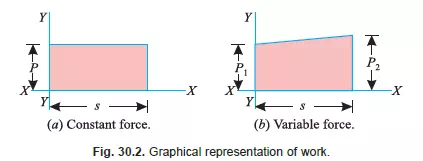

GRAPHICAL REPRESENTATION OF WORK

The work done, during any operation, may also be represented by a graph, by plotting distance along X-X axis and the force along Y-Y axis as shown in Fig. 30·2 (a) and (b).

Since the work done is equal to the product of force and distance, therefore area of the figure enclosed, represents the work done to some scale. Such diagrams are called force-distance diagrams. If the force is not constant, but varies uniformly with the distance, the force distance diagram is not a rectangle; but a trapezium as shown in Fig. 30·2 (b).

POWER

The power may be defined as the rate of doing work. It is thus the measure of performance of engines. e.g. an engine doing a certain amount of work, in one second, will be twice as powerful

as an engine doing the same amount of work in two seconds.

UNITS OF POWER

TYPES OF ENGINE POWERS

In the case of engines, the following two terms are commonly used for power.

1. Indicated power. 2. Brake power.

INDICATED POWER

The actual power generated in the engine cylinder is called indicated power (briefly written as I.P.). Sometimes, the indicated power is also defined as the power, which is fed into the engine

in the form of steam or calorific value of the fuel.

BRAKE POWER

It has been observed that the entire power, generated by the engine cylinder, is not available for useful work. This happens because a part of it is always utilized in overcoming internal friction

of the moving parts of the engine. The net output of the engine (i.e. I.P. – Losses) is called brake power (briefly written as B.P).

EFFICIENCY OF AN ENGINE

MEASUREMENT OF BRAKE POWER

The brake power of an engine is measured by an apparatus called dynamometers (or brake). Following are the two types of dynamometers :

1. Absorption type, and

2. Transmission type.

In the absorption type dynamometers, the entire power, available from the engine, is wasted in friction of the brakes during the process of measurement. But in the transmission type dynamometers, the entire power available from the engine is transmitted to some other shaft, where it is suitably measured. Following are the common types of dynamometers :

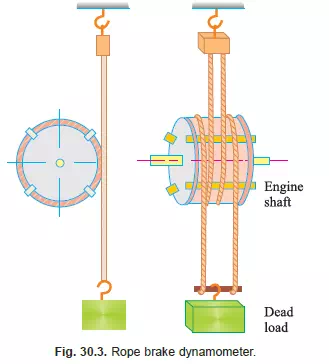

ROPE BRAKE DYNAMOMETER

It is the most commonly used absorption type of dynamometer used for the measurement of brake power. It consists of one, two or more ropes looped around the flywheel or rim of a pulley, fixed rigidly to the shaft of an engine whose power is required to be measured. The upper end of the ropes is attached to a spring balance, whereas the lower end of the ropes is kept in position by hanging a dead load as shown in Fig. 30·3.

In order to prevent the rope from slipping over the flywheel and to keep it in position, some wooden blockes are placed at intervals around the circumference of the flywheel.