Working principle of gear change and gear shifting

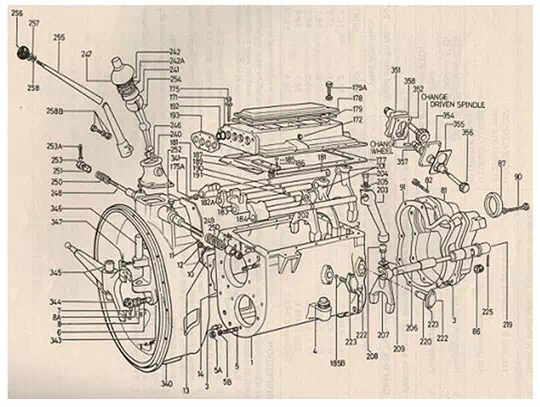

In a gear box arrangement is provided on the top for gear changing mechanism. This includes gear changing lever, gear changing spindles, gear forks etc. The Fig 16.1 shows various components which go in to form the gear housing and the gear changing mechanism.

Fig 16.1 Exploded view of the gear box along with the gear selector mechanism

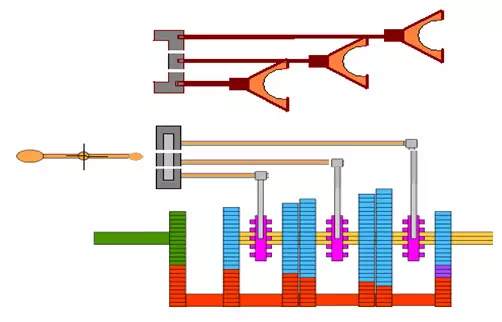

As discussed in the previous lesson, either the gear (in case of sliding mesh gear box) or the sliding dog collar (in case of constant mesh and synchromesh gear box) are slid (pulled or pushed) using the gear changing lever while selecting the appropriate gear (speed-ratio). The gear lever is provided to the operator, who has the control of the system. There is swivel pin at the lower end of the gear shifting lever. This swivel pin moves within the box shaped cavity provided at the selector rod jaws. Movement of the gear lever also moves the swivel pin to select the selector rod out of the 3-4 rods provided in the gear selector cover. Fig 16.2 (a) and (b) shows two views of the gear selector mechanism, showing the various components involved in the gear changing mechanism

Each of the gear selector rods has a gear selector fork. This fork is sitting on the collar shaped gear (or sliding dog clutch as the case may be). When the selector rod is moved, the fork pushes or pulls the collar of the gear for meshing as required.

Fig 16.2 Arrangement showing the different components involved in gear changing mechanism which the

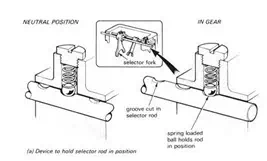

1- Selector detent-

Holds the gears and selectors in position and so prevent gear engagement or disengagement due to vibration. The figure shows a typical arrangement suitable for a layout having the selector fork locked to the rod.

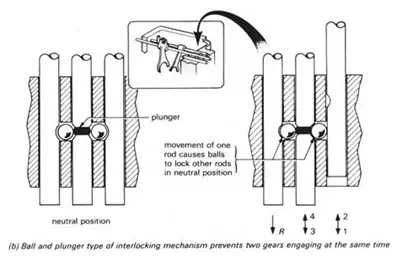

2-Interlock mechanism-

Prevents two gears engaging simultaneously; if this occurs the gearbox will lock up and shaft rotation will be impossible. Although the interlock device takes a number of different forms, the arrangement shown in the figure is one of the most common.