Calculations of number of clutch plates

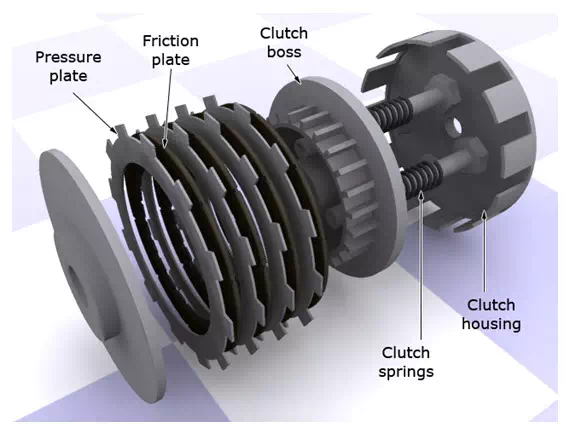

Multi Plate Clutch

A multi plate clutch is an extension of a single plate clutch where the number of friction surfaces is increased. Due to this increase in number of frictional surfaces, the area which transmits torque is increased which in turn increases the capacity of the clutch to transmit torque. This type of clutch finds its application in case of heavy torque transmission or where there is limitation of space available.

Method of working

The construction of the pressure plates and the clutch plates is such that the pressure plates have teeth at its outer periphery, or it is grooved from outside. This is done so that the teeth on the pressure plates mesh with the corresponding grooves on the flywheel. The clutch plates are grooved on the inside periphery to sit on the splines of the clutch shaft.

The pressure plates are meshed in the grooves on the flywheel and are free to move away from or towards the flywheel depending on whether the clutch pedal is released or pressed. When the clutch pedal is pressed, the axial force binding the clutch plates is removed, stopping the power being transmitted by the clutch.

The number of clutch plates to be used is decided by the total surface area of the clutch plate in contact with the flywheel or pressure plate driving the clutch plates. Mathematically the torque transmitted by the clutch as discussed in lesson 10, is given by:

T= uFR

This relation holds for single contact surface.

For a single plate clutch with two contact surfaces, the torque transmitted is T= 2uFR

For a clutch with ‘n’ number of plates, the torque transmitted is given by:

T= 2nuFR

Numerical:

An automobile whose engine develops

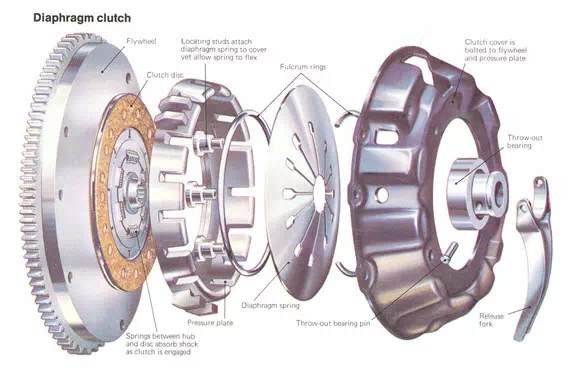

Diaphragm type clutch

The construction of this type of clutch is similar to that of the single plate type clutch described earlier except that in this case the axial force is exerted by a curved diaphragm instead of a series of axial springs.

The axial spring type clutch has got axial springs for exerting the axial force for clutching together the clutch plate to the flywheel. These springs are of compressive type, i.e. compressive force needs to be applied to disengage the clutch plate. Each of these axial springs need huge amount of force to be pressed. When these are combined, the force required for disengagement increases multifold.

In the free condition, the diaphragm spring is conical in shape, but when assembled, it is constrained to an approximate flat condition due to which the force is exerted on the pressure plate.