Repulsion-start, induction-run motors

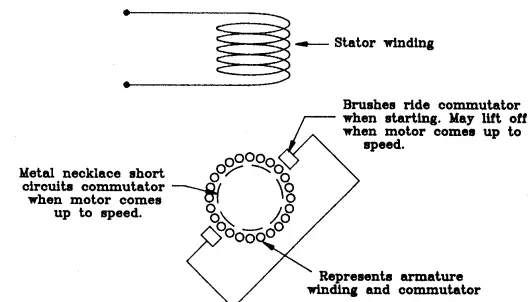

A repulsion-start, induction-run motor is illustrated schematically in Figure 3.8. Unlike the previous induction motors, the repulsion-start motor does not use auxiliary starting windings on the stator. Instead, a wound rotor is used. Unlike the squirrel-cage rotor in which all of the conductor bars are shorted together by washer-shaped end plates, the conductors of the wound rotor are brought out to commutator segments, that is, the rotor is an armature. The two brushes which ride on opposite sides of the commutator are shorted together, as shown in Figure 3.8. Thus, at any instant, one set of windings on the armature are connected into a coil whose axis is tilted relative to the axis of the stator winding. The stator magnetic field induces a current in the coil on the armature which, in turn, generates a magnetic flux from the armature coil. The repulsion of the stator and armature electromagnets forces the armature to turn. After the motor comes up to speed, a centrifugal device shorts all of the commutator segments together and the motor runs similar to a squirrel-cage induction motor. The direction of rotation can be changed by shifting the angle of the brushes relative to the axis of the stator coil. The repulsion-start, induction-run motor develops very high starting torque with relatively low starting current and is available in sizes from 0.37 to 7.5 kW (1 /2 to 10 hp). However, because of the high cost of manufacturing the armature, the repulsion-start, induction-run motor is less widely used than the capacitor-start and two-value-capacitor motors.

Figure 3.8 – Illustration of a repulsion-start, induction-run motor.