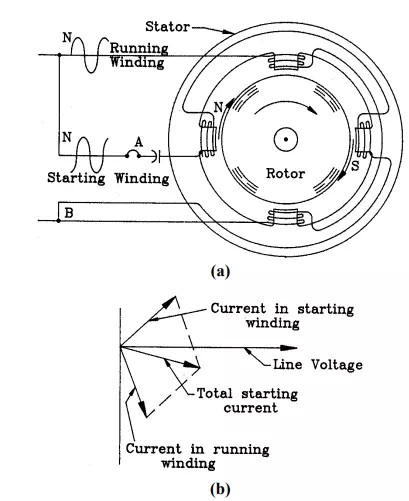

Capacitor-start, induction-run motors

A capacitor-start, induction-run motor is illustrated in Figure 3.6a. An electrolytic capacitor has been inserted in series with the starting windings to shift the phase of the starting current as shown in Figure 3.6b. The electrolytic capacitor is not designed for continuous duty and thus, when the motor reaches 75% to 80% of synchronous speed, a centrifugal switch opens and disconnects the starter-winding circuit. Comparing Figures 3.5b and 3.6b shows that the capacitor-start motor has much lower starting current than the split-phase motor; typically, the starting current of the capacitor-start motor is three to four times that required for running. The starting torque capability of the capacitor-start motor is typically is about twice that of a split-phase motor. The capacitor-start, induction-run motor is available in sizes from 0.13 to 2.3 kW (1 /6 to 3 hp) and is the most widely used motor for farm equipment. As with the split-phase motor, the direction of rotation can be reversed by reversing the leads, A and B, to the starter-winding circuit.

Figure 3.6 – Illustration of a capacitor-start induction-run motor

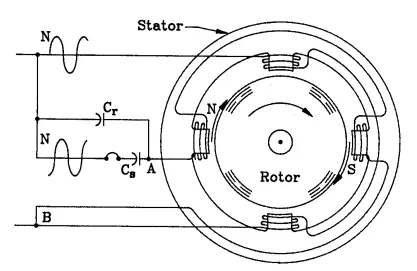

Illustration of a two-value-capacitor, induction-run motor