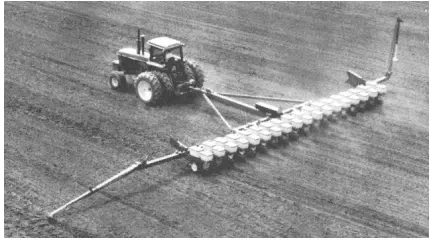

Precision planting

Precision planters provide accurate placement of single seeds at equal intervals within rows; the rows are usually spaced widely enough to allow cultivation (Figure 9.4). Precision planters are available in many variations, but four functions are always included. These are: opening a furrow of controlled depth, metering seeds into the furrow at uniform intervals, covering the furrow, and firming the soil against the seeds. On some planters, a pair of inclined wheels accomplish both the covering and the soil firming. Until the mid-1960s, most precision planters included seed plates for metering seeds. Pockets along the periphery of the plates were sized to match the seed dimensions, so that only one seed could fit in each pocket. As each pocket passed the seed tube, a spring-loaded knockout device would push the seed into the tube. Plates were easily replaceable, and farmers kept sets of plates to match each size of seed that was to be planted. “Plateless” planters were developed in the late 1960s and now there are a wide variety of mechanisms available for metering seed. The term punch planting is used to describe planting in dibbles created by a spaded wheel rather than planting in furrows. When vegetable crops are to be grown in soil covered by a plastic sheet, punch planting is especially useful in planting through the plastic cover.

Figure 9.4 – A precision planter