Drilling

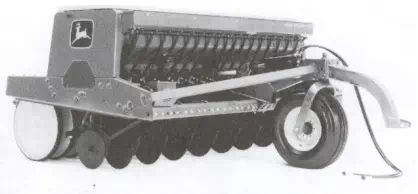

A drill seeder is illustrated in Figure 9.2. Typically, for each row, the seeds are metered from a hopper by a ground-driven fluted wheel past an adjustable gate that controls the seeding rate. The seeds then enter a tube and fall by gravity to a furrow that has been opened by a disk. Typical row spacings range from 150 to 400 mm. A common method of covering the seeds is to pull a small drag chain behind each furrow opener. Figure 9.2 is an example of a wheel drill, in which the weight of the machine is carried on transport wheels. In the press drill illustrated in Figure 9.3, much of the weight of the drill is carried on press wheels that follow each row. Press drills thus provided firmer soil around the seeds compared to wheel drills. The term fluid drilling has been used to describe a planting technique in which germinated seeds are sown using a protective gel. The gel and seed mixture can be pumped through a hose for transport to the furrow if seed spacing is not critical. For more uniform seed placement, Shaw (1985) was issued a patent for a device to singulate and meter seeds from a liquid gel or suspension.

Figure 9.2 – A drill seeder

Figure 9.3 – A press drill