Cultivators

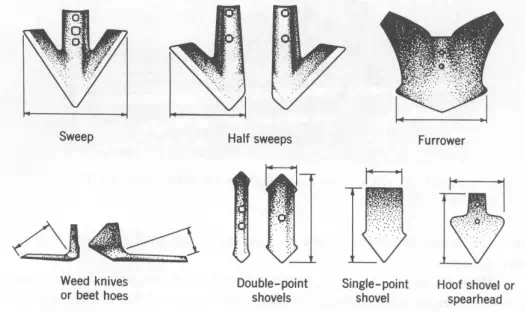

There are basically three types of cultivators: field cultivators, row crop cultivators, and rotary cultivators. Field cultivators are often used as secondary tillage tools for seedbed preparation. They are similar to chisel plows in appearance but they operate at much shallower depths. Figure 8.16 shows the different types of tools that can be attached to a cultivator shank for different applications. Field cultivators may be either mounted or pull type with wheels for depth control. Some very large units are designed to be folded while transporting. The lateral tine spacing may vary from 15 to 30 cm. Usually two or three rows of tines are used with fore and aft spacing ranging from 50 to 80 cm. Row crop cultivators have the tines spaced to go between the crop rows. They are used for cultivation and weed control operations during the active growth period of crops planted in rows.

Rotary hoes and rotary cultivators

Rotary hoes and cultivators, unlike rotary tillers, are not powered. They are both designed to operate at shallow depth and are used for weed control in row crops, breaking soil crests for better seedling emergence, and mixing of fertilizer.

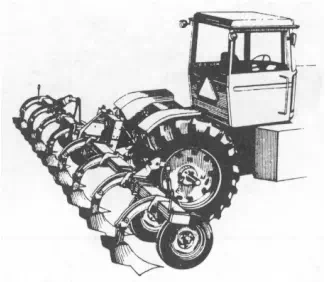

Rotary hoes are made of several star wheels, often called spiders, mounted on a shaft at a spacing of about 15 cm to form a gang. Each spider has 10 to 16 teeth and the tip diameter ranges from 45 to 50 cm. Two staggered parallel gangs make a section and provide a working width of about 8 to 10 cm. Several sections are used in a given implement. The section width is such that they fit between the rows for row crop cultivation. The teeth in a rotary hoe have forward curvature for more aggressive cultivation. A rotary hoe is shown in Figure 8.17.

Figure 8.16 – Cultivator tools

Figure 8.17 A rear mounted rotary hoe with in-line sections on spring-loaded arms.

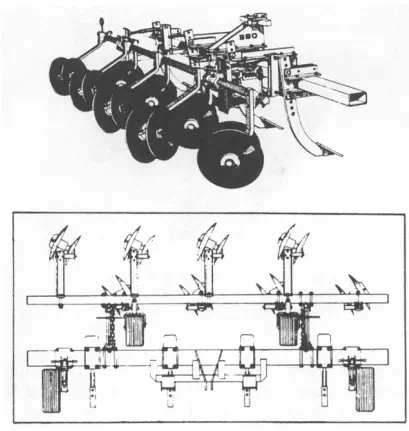

Figure 8.18 A rear-mounted, row crop rotary cultivator with ground-driven finger wheels.

Figure 8.19 – Rollers and culti-packer

Rotary cultivators have spiders similar to rotary hoes but the teeth are twisted and the ends are shaped like chisels. This creates a sideways movement of the soil. Only two spiders are mounted on a shaft, and each shaft is located at an angle from the forward line of travel. The spider wheels turn backward as the implement is pulled forward creating the necessary tilling action. The cultivator may be arranged to cultivate row crops or the entire field. A rotary cultivator is shown in Figure 8.18.

Culti-packers, rollers, and finishing boards

Often in dry conditions or when the soil has many clods, culti-packers, rollers (Figure 8.19), or finishing boards are used to break up soil clods and to conserve moisture for better seed germination. These tools are used almost always as attachment to harrows just before seeding.

Listers

Listers (Figure 8.20) look like double moldboard plows. They are used to create furrows for planting. Sometimes it is desirable to plant in furrows as opposed to on a flat surface to protect the plants from wind and to place seed down near the moisture. These ridges are flattened due to the cultivation performed during the growing season so by the time of harvest the field is level. Often planters are attached to listers to accomplish planting in the same operation.

Figure 8.20 – A rear-mounted mold-board lister with wheels for depth control.

Figure 8.21 – A rear-mounted bedder-ridger with disk-staggered gangs. Shown with a subsoiler.

Bedders

Bedders are used to make ridges or beds when it is desirable to plant on a higher soil level in areas of high rainfall. Bedders are made of disk implements that work in pairs to form the ridges as shown in Figure 8.21.

Tillage in conservation tillage systems

Conservation tillage systems are designed to conserve soil, water, and/or energy. In areas prone to wind soil erosion, it is advisable to leave surface cover on the soil to prevent or minimize soil erosion. Any primary tillage operation that turns the soil over and buries the surface residue under the soil is eliminated. In heavy soils subjected to compaction due to wheel traffic, it is recommended that primary tillage performed during the wet spring season be eliminated. In this situation weed control is accomplished by use of herbicides. Generally, conservation tillage systems require some other changes to be made in the methods and equipment. For example, planter changes are needed to cut through the surface residue in order to plant seeds. This is accomplished by adding a fluted coulter ahead of the furrow openers.

There are different levels of conservation tillage: minimum tillage, strip tillage, and zero tillage. Zero tillage system consists of no primary or secondary tillage operation. In a strip tillage system, a small band or strip of soil is tilled and the crop is planted in this strip. Elimination of any primary or secondary tillage operation results in the minimum tillage system.