Stubble-mulch plows and Tillers

Stubble-mulch plows are made of wide V-shape sweeps that operate at shallow depth of 10 cm or less. The purpose is to cut weed roots just below the surface and leave the stubbles of the previously harvested crops on the surface to act as mulch (cover) to retain moisture and reduce soil erosion. The width of each sweep is in the range of 1.5 m. There may be several sweeps on a plow. Very wide plows have folding wings that fold during transport. These plows may be used as primary tillage tools right after the harvest or as secondary tillage tools before planting. When used for primary tillage it may be necessary to mix some surface residue into the soil using a disk tiller or a disk harrow (see below) before planting.

A stubble-mulch tiller is a combination of a chisel plow and a disk harrow. The disk section is in the front to cut stubbles, such as corn stalks, while the rear section is the chisel plow to accomplish deep tillage. Stubble-mulch tilllers are used where it is essential to till deep to break old plow pan but it is not necessary to leave all crop residue for erosion control. Mixing some of the crop residue helps to improve organic matter in the soil.

Rotary tillers

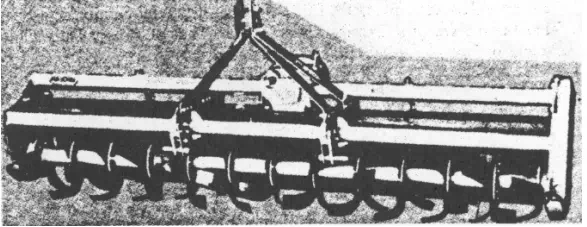

Rotary tillers are also called power tillers because the power is transferred to the tiller from the tractor via the power-take-off drive. A shaft containing blades is located at 90° to the line of travel and rotates in the same direction as the forward travel of the tractor. Since the shaft turns at a rate that is considerably faster than the corresponding tractor speed, soil pulverization is accomplished. Also, the tiller pushes the tractor forward and generates a negative draft. Consequently, lighter tractors can be used for rotary tillage operations. Total power requirements for rotary tillers are generally higher than for conventional plows. However, one rotary tillage operation may be equivalent to several conventional tillage operations as far as the quality of the seed bed is concerned. Figure 8.11 shows a rotary tiller.

Figure 8.11 – A rear-mounted full width rotary tiller.