Disk plows

The common disk plow consists of a series of disk blades mounted individually on a frame as shown in Figure 8.6. The disk blades are set at an angle, called the disk angle, from the forward line of travel, and also at a tilt angle from the vertical, as shown in Figure 8.7. Standard disk plows usually have three to six blades, spaced to cut 18 to 30 cm/disk. The disk angles vary from 42° to 45° and the tilt angles vary from 15° to 25°. The disk diameters are commonly between 60 and 70 cm.

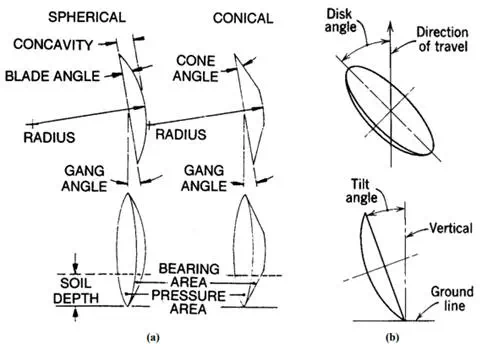

The disks used in the disk implements are either conical or spherical (i.e., sections of hollow spheres). Both blades have a spherical radius associated with the concavity of the blades as shown in Figure 8.7. A conical blade has its outside surface flattened to a specific cone angle. The blade angle of a spherical blade is defined as the tangent at the edge surface area of the blade.

Disk plows are used for primary tillage and are available in integral, semi-integral, and drawn hitching configurations. They are most suitable for conditions under which moldboard plows do not work satisfactorily, such as in hard, dry soils, and in sticky soils where a moldboard plow will not scour. Scrapers, furnished as standard equipment on most disk plows, assist in covering plant residue and inverting the soil and prevent soil buildup in sticky soils. Reversible disk plows have an arrangement whereby the disk angle can be reversed at each end of the field to permit one-way plowing.

Figure 8.7 – (a) Disk blade geometry (b) disk and tilt angles

Under most conditions, and particularly in hard, dry soils, any disk tool must be forced into the ground by its weight rather than depending upon suction as does a moldboard plow. Consequently, disk plows are built with heavy frames and wheels (total masses of 180 to 540 kg/disk blade), and even then additional mass must sometimes be added to obtain a desired depth. The soil penetration ability of a disk plow depends upon disk diameter, tilt angle, and disk angle. Whereas the moldboard plow absorbs side forces mainly through the landsides, a disk plow must depend upon its wheels for this purpose.

A standard disk plow does not have special attachments to protect its disk blades from damage due to impact with rocks buried in the soil. Usually, the disk plow is able to withstand impact forces because of its heavy frame and its lower operating speed.