Primary tillage in conventional tillage systems

Most farmers use only one primary tillage operation after harvesting a crop. An exception is when a farmer uses a subsoiler in the fall shortly after harvest followed by another primary tillage in the spring. Implements used for primary tillage are moldboard plows, disk plows and tillers, chisel plows, subsoilers, stubble-mulch plows and tillers, rotary tillers, listers, and bedders.

Moldboard plows

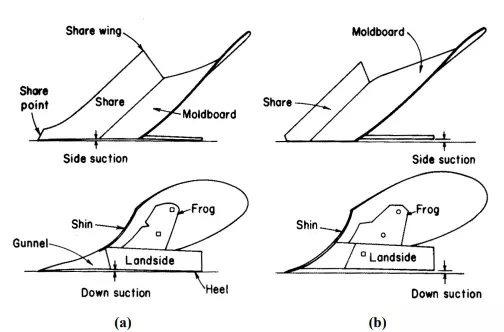

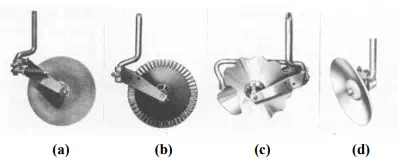

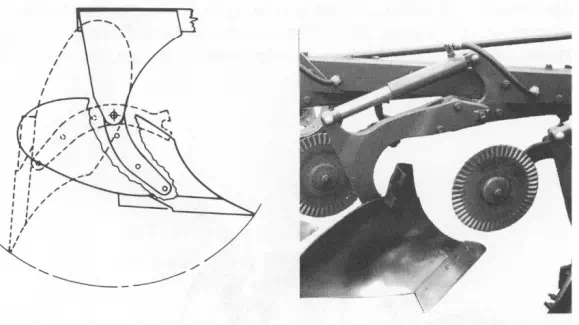

All moldboard plows are equipped with one or more tillage tools called plow bottoms (Figure 8.1). Each plow bottom is a three-sided wedge with the landside and the horizontal plane of the share’s cutting edge acting as flat sides and the top of the share and the moldboard together acting as a curved side. The primary functions of the plow bottom are to cut the furrow slice, shatter the soil, and invert the furrow slice to cover plant residue. Most moldboard plows are also equipped with tillage tools called rolling coulters (Figure 8.2) to help cut the furrow slice and to cut through plant residue which might otherwise collect on the shin or plow frame and cause clogging. The vertical edge of the furrow slice left uncut by the rolling coulter is cut by the shin. The bottoms along with the rolling coulters are responsible for the process function of the moldboard plow.

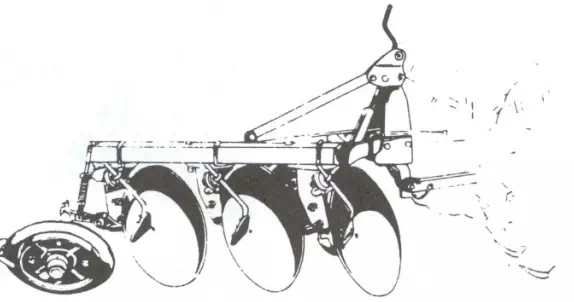

Moldboard plows are the most common implement used for primary tillage, but they are never used for secondary tillage. They are usually equipped with adjustments to ensure that the plow is level in the longitudinal and lateral directions and that the plow bottom is oriented with the landside parallel to the direction of travel. A fivebottom moldboard plow is shown in Figure 8.3.

Figure 8.1 – Typical moldboard plow bottoms, (a) with gunnel-type share, showing method of measuring suction when no rear furrow wheel or depth control devices are used, (b) with throw-away share, indicating clearances when a rear furrow wheel is used.

Figure 8.2 – (a) Plain coulter with spring, (b) ripple-edge coulter, (c) notched coulter with jointer attachment, (d) concave coulter or disk jointer

Figure 8.3 – A semi-integral five-bottom moldboard plow bottom.

Integral moldboard plows have the lowest purchase price and the best maneuverability for small and irregular fields. However, they are limited in size due to tractor stability and the lift capacity of the hitch. The furrow transport wheel of a semiintegral plow is automatically steered to provide more maneuverability than for a drawn plow. Both integral and semi-integral plows improve a tractor’s traction by applying a downward force on the hitch. Drawn plows provide the most uniform plowing depth, but have the highest purchase price.

Moldboard plows are frequently equipped with automatic reset standards that allow a plow bottom to move rearward and upward to pass over an obstacle, such as a rock, without damage. A hydraulic cylinder or a spring mechanism automatically moves the bottom to its original position after it passes over the obstacle (Figure 8.4).

Most moldboard plows are designed to turn the furrow slices only to the right. Two-way plows, however, have two sets of opposed bottoms that can be used selectively. With this arrangement, all the furrows can be turned toward the same side of the field by using the right-hand bottoms for one direction of travel and the left-hand bottom on the return trip. The two sets of bottoms are mounted on a common frame that is rotated 180° about a longitudinal axis to change from one set to the other as shown in Figure 8.5. In most cases, rotation is accomplished with a hydraulic cylinder

Figure 8.4 – Spring-trip (left) and hydraulic reset mechanisms (right) used as overload protection devices for moldboard plows

Figure 8.5 – A rear-mounted two-way plow.

Figure 8.6 – A mounted three-bottom disk plow.