Plant Protection Equipment

Sprayers

Sprayer is a machine to apply fluids in the form of droplets. Sprayer is used for the following purpose.

∗ Application of herbicides to remove weeds.

∗ Application of fungicides to minimize fungus diseases.

∗ Application of insecticides to control insect pests.

∗ Application of micro nutrients on the plants.

The main function of sprayer is

∗ To break the liquid droplets of effective size.

∗ To distribute them uniformly over the plants.

∗ To regulate the amount of liquid to avoid excessive application.

Basic Components of Sprayer

Components of a sprayer are as follows

(1) Nozzle body

(2) Swirl plate

(3) Filter

(4) Over-flow pipe

(5) Relief valve

(6) Pressure regulator

(7) Cut-off valve

(8) Spray boom

(9) Drop legs

(10) Nozzle boss

(11) Nozzle disc

(12) Nozzle cap

(13) Nozzle tip

(14) Spray lance

(15) Spray gun.

Nozzle body - It is the main component on which another component of a nozzle fit

Swirl plate - It is the part of a cone nozzle which imparts rotation to the liquid passing through it

Spray gun - It is a lance from which spray is readily adjustable during the operation. Spray boom - It is a spray lance with spray nozzles fitted to a head, mounted at right angles to the lance

Filter - It is a component to remove suspended matter larger than a predetermined size from fluid.

Over-flow pipe - It is a conduit through which excess fluid from a pump is by-passed by the action of a relief valve or pressure regulator.

Relief valve - It is an automatic device to control the pressure of fluid or gas within range a predetermined value.

Pressure regulator - It is an automatic device to control the pressure of fluid or gas within a range of settings.

Cut-off valve - It is a mechanism between the pump and the nozzle to control the flow of liquid from the sprayer. This is operated by hand.

Nozzle disc - It is component containing the final orifice of a nozzle usually a cone nozzle.

Nozzle boss - It is a lug on spray boom or spray lance to which a nozzle body or cap is screwed.

Nozzle tip - It is component containing the final orifice of a nozzle usually a fan nozzle. Spray lance - A hand-held pipe through which the liquid reaches the nozzle mounted at the free end.

Type of Spray

(1) High volume spray (more than 400 litres spray/ha)

(2) Low volume spray (5 to 400 litres, per hectare)

(3) Ultra low volume (ULV) spray (less than 5 litres spray/ha).

High volume spray

The dilute liquids are applied by hydraulic machines. It consumers more time and labour.

Low volume spray

It uses air steam from a fan as a pesticide carrier with small quantities of liquid. There is saving of material spraying.

Ultra-low volume sprayer

The sprayer has a motor powered by 6 to 12-volt battery and is attached with a spinning disc, having grooves or teeth and rotates at a very high revolution per minute (4000- 9000). The spinning disc receives the concentrated chemical from a plastic container having a capacity of 1 litre (approx.). Average droplet size varies between 35-100 micron. It is used for application of weedicide and for spraying small trees and crops.

Types of Nozzle

The three common types of nozzle

(a) Hollow cone nozzle

(b) Solid cone nozzle

(c) Fan type nozzle.

(a) Hollow cone nozzle

This liquid is fed into a whirl chamber through a tangential entry or through a fixed spiral passage to give a rotating motion. The liquid comes out in the form of a harrow conical sheet which then breaks up into small drops.

(b) Solid cone nozzle

This nozzle covers the entire area at small range. The construction is similar to hollow cone nozzle with the addition of an internal jet which strikes the rotating liquid just within the orifice of discharge. The breaking of drop is mainly due to impact.

(c) Fan nozzle

It is a nozzle which forms narrow elliptical spray pattern. In this type the liquid is forced to come out as a flat fan shaped sheet which is then broken into droplets. This nozzles is mostly used for low pressure spraying.

Hand atomizer

This sprayer has a container of 0.5 to 3.5 litres capacity. The container has inside a built-in pump. While in other cases, the air pump is mounted externally. In both the cases, the air pump outlet pipe is suspended in the container. The outer end of the pipe terminates in a nozzle with 0.6 – 1.6 mm diameter orifice. The container is filled to approximately three- fourth of its capacity and air is compressed on the remaining space by means of the pump. Before use, the plunger type pump is worked to develop an air pressure of 0.15 – 0.35 kg/cm2. The spray comes out from the nozzle usually via. a suitable trigger control valve. The application rate ranges from 18 to 45 litres per acre.

Hand compression sprayer:

These sprayers are similar to the hand atomizer but are adopted for spraying large quantities of liquids. They are more easily operated than the knapsack sprayer. The typical hand compression sprayer comprises a tank for holding spray material and compressed air, vertical air pump with a handle, filling port, spray lance with nozzle and release and shut-off devices. Besides, it has a metal or plastic skirt which protects the bottom of the tank of the sprayer against wear and makes the sprayer stable when placed on the ground. It also serves as a base for the back- rest. In addition, it has adjustable straps. These should be made of cotton belt, leather on plastic. As the spraying proceeds, the pumping is required to maintain the normal pressure of 2.0 – 3.5 kg/cm2 .

Knapsack hand compression sprayer

It has a flat or bean-shaped tank designed to fit comfortably on the back of the operator. The capacity of the tank is 10-20 litres. It is generally, made of galvanized, iron, brass or stainless steel. Recently, plastic material has also been used for the construction of the spray tank. It is more expensive than the bucket pump, but is similar to its in principle. In some cases, it is provided with a built-in double barrel spray pump of piston or diaphragm type with a lever for operating. In other cases, the tank is provided with a single pump and pressure having a plunger pump and mechanical agitator. Higher outputs are provided by the plunger type pumps, than by the diaphragm pumps. However, the later type of pumps requires comparatively less energy for operation and also less maintenance.

The pressure developed in these sprayers depends on the pump and varies from 3 to 12 kg/cm2 which is more than that developed in a hand compression sprayer. However, a pressure of 3-4 kg/cm2 can be maintained in most cases without much effort. The sprayer can be used for spraying row crops, vegetables and nursery stocks and shrubs and trees 2-2.5m high. The coverage is 0.5-1.0 ha/day.

Rocker sprayer

This sprayer consists of pump assembly, platform with frame and fork, operating lever, pressure chamber, suction hose with strainer, delivery hose, extension rod with spray nozzles, etc. The rocking movement of the handle helps in building pressure in the pressure chamber. There is no built-in tank and separate spray tank is necessary. The sprayer builds up a high pressure of 14-18 kg/cm2. In some it may be as much as 36 kg/cm2. It can therefore be used for spraying the field crops. The sprayer is popular in some of the coconut and are canut areas. Long hose connections up to 30 m are made to one or two outlets.

Foot or pedal sprayer

The foot or pedal sprayers, as they are commonly called, consist of plunger assembly, stand, suction hose, delivery hose, extension rod with a spray nozzle etc. One end of the suction hose is fitted with strainer and the other with a flexible coupling. Similarly, the delivery hose has one end fitted with a sheet off pistol and the other with a flexible coupling. Foot instead of hand operates it, but the principle is the same as in case of the rocker sprayer. The pump is fitted on iron stand and a pedal attached to the plunger rod operates the sprayer by its upward and downward movement. This sprayer also does not have a built-in tank. Constant pedalling is required for continuous spray. It develops a pressure of 17-21 kg/cm2. It is easy to operate and can be used for spraying tall crops as well as fruit trees.

POWER SPRAYER

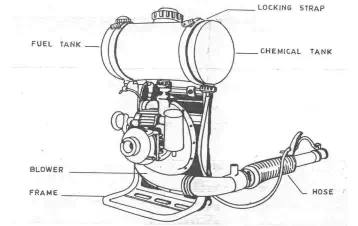

Motorized knapsack sprayer:

Knapsack motorized sprayer are the versatile and simple power operated machines. The spray liquid is flown out by means of an air current generated in the machine. They deliver 6.8 to 42.5 m3 (240 to 1500 ft3) of air per minute at a velocity of 200-420 km (125- 260 miles) per hour at the nozzle. The tank, which has a capacity of 10-12 lit, is mostly made of high density polyethylene (Fig.). Another small tank of 10-15 lit capacity is provided for the fuel. They are light, weighing 12-20 kg including accessories. Generally, they are powered by 1.2 – 3.0 hp petrol engines and the frame is provided with shock-proof cushion which comfortably fix on the back of the operator to eliminate vibrations of the engine. The delivery hoses are very small.

Some manufacturers also provide diffuser and deflector accessories with the delivery hose for adjusting the swath according to requirements. It is advisable not to load the tank to its full capacity. About half a litre space should be left to provide for air cushion. A part of the air generated by the blower is directed into the tank to form air cushion over the liquid within the tank. Liquid from the tank passed through a tube to the nozzle on the spray lance by gravity, partly helped by the air pressure exerted over the liquid within the tank. The machine, when fitted with a rotary pump and high tree lance can spray trees about 8 m high. The discharge rate can be adjusted differently and varies in different makes taking 0.4 to 3.0 minutes to discharge one litre. Effective width is 7-8 m horizontally and 5-6 m vertically. A power sprayer essentially consists of: (i) Prime mover (ii) Tank (iii) Agitator (iv) Air-chamber (v) Pressure gauge (vi) Pressure regulator (vii) Strainer (vii) Boom (ix) Nozzles.

(i) Prime mover –

Prime mover is needed to supply power to the power sprayer. It is usually combustion engine. The power generally varies from 1 to 5 HP.

(ii) Tank –

Steel tank is widely used to prevent corrosion. Plastic tanks are also getting popular due to freedom from corrosion and ease of moulding into smooth shapes. A covered opening, fitted with a removable strainer is provided for easy filling, inspection and cleaning. A drain plug is there at the bottom of the tank for draining the liquid.

(iii) Agitator –

Agitator are needed to agitate the liquid of the tank. Propeller or paddle type mechanical agitators are provided for agitating the liquid. Horizontal shaft may be used with 5 AG ENGG 243 Lecture 15 flat blades rotating at about 100 to 120 rev/min. paddle tip seeds in excess of 2.5 m/sec may cause foaming.

(iv) Air chamber –

An air chamber is provided on the discharge line of the pump to level out the pulsations of the pump thereby providing a constant nozzle pressure.

(v) Pressure gauge –

The pressure gauge is provided on the discharge line to guide the operator regarding spray pressure. The spray pressure should be under specified limit.

(vi) Pressure regulator –

It is meant for adjusting the pressure of the sprayer according to the requirement of the crops in the field.

(vii) Strainer -

A strainer is included in the suction line between the tank and the pump to remove dust, dirt and other foreign materials.

(viii) Boom –

Field sprayer to be driven by a tractor has a long boom in a horizontal place on which nozzles are fixed at specified spacing. The boom can be adjusted vertically to suit the height of plants in different fields.

(ix) Nozzle –

It is used to break the liquid into the desired spray and deliver it to plants. A nozzle consists of: (a) body (b) screw cap (c) disc (d) washer (e) vortex plate (f) strainer.

Usually the flow rate for a particular nozzle is proportional to the square root the pressure and the discharge rate is proportional to the orifice area. Nozzles have smaller angles. Operating pressure below 1.5 kg/cm2 is undesirable because the nozzle does not work satisfactory.

Hand Rotary Duster

This consists basically of a blower completely with a gearbox and a hopper. It is operated by rotating the crank. The cranking motion is transmitted through the gearbox to the blower. A drive is taken from the dust agitator located in the hopper. The rotary duster may be hand carried type or shoulder mounted or hand carried type. The feeder is controlled by a feed control lever, which operate a slide to control the aperture at the bottom of the hopper.

Motorized knapsack duster

Knapsack dusters are common in India. The capacity of the hopper is about 9 kg. The discharge of the dust can be controlled by rotating the plated hose on the blower elbow, which carries the discharge hose. In the spraying cum dusting unit, the conversion of sprayers to duster is very simple and effected by replacing the liquid feed tubes by appropriate dust feeds. Agitation is provided by directing a part of air from the discharge. The dust tank may be the same as for the spray unit except that all the liquid feeds are removed. In some cases, there is a separate unit for replacing the spray lance. Part required for conversion of a sprayer into duster can be purchased at nominal cost from the suppliers of knapsack sprayers cum dusters.

Battery operated sprayer

The battery-operated sprayer developed consists of a 10-lit capacity plastic tank and a 6 Volt rechargeable battery both fixed in a frame which is carried on the back of the operator. A plastic spinning disc along with a micro motor is fitted at the end of an aluminium handle. Chemical is taken from the tank to the spinning disc through a plastic hose. A cut off valve is provided in the hose line to stop of flow of spray fluid when desired. The salient features of the unit are light in weight, less water requirement & low cost.