Engine Cycles

Basic Engine cycles:

Most internal combustion engines both spark ignition and compression ignition operates on either a four stroke cycle or a two stroke cycle. These basic cycles are fairly standard for all the engines.

Four stroke Spark Ignition (Petrol) engine

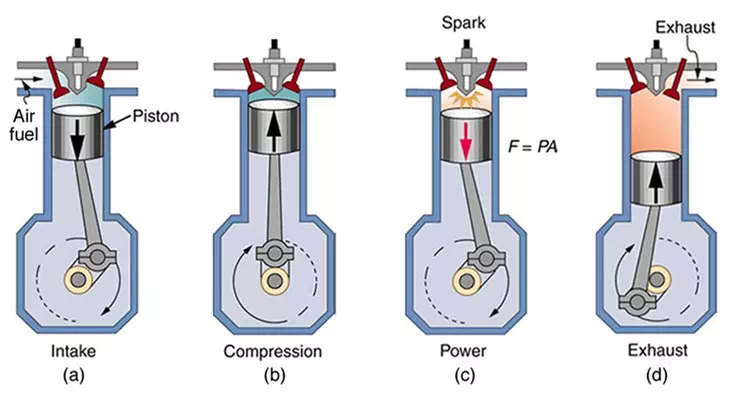

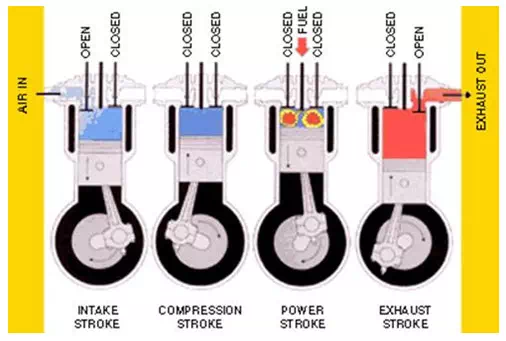

First stroke : Suction stroke

It is also known as intake stroke when the piston travels from TDC to BDC with the intake valve open and exhaust valve closed. The downward motion of the piston increases the volume in the combustion chamber which in turn creates a vacuum. The resulting pressure differential through the intake system from atmospheric pressure on the outside to the vacuum on the inside causes air to be pushed into the cylinder. As the air passes through the intake system, fuel is introduced into the cylinder in the desired amount with the help of fuel injectors or carburetor.

Second stroke : Compression stroke

At the end of suction stroke, when the piston reaches BDC, the intake valve gets fully closed and the piston travels upward back to TDC with both the valves (inlet and outlet) closed. As the piston moves upward, it compresses the air-fuel mixture raising both the pressure and the temperature inside the cylinder. Near the end of the compression stroke, the combustion is initiated with the help of spark plug. The combustion of an air-fuel mixture occurs in a very short but finite length of time with the piston near TDC. Combustion changes the composition of the gas mixture to that of exhaust products and increases the temperature in the cylinder to a very high peak value.

Third stroke : Power stroke

This is also known as the expansion stroke when the piston moves again downward from TDC with the pressure being generated by the fuel burnt having both the valves fully closed. This is the stroke which produces the work output of the engine cycle. As the piston travels from TDC to BDC, cylinder volume is again increased causing pressure and temperature drop. Late in the power stroke, the exhaust valve is opened and exhaust blow down occurs. The pressure and temperature in the cylinder are still high relative to the surroundings at this point and a pressure differential is created through the exhaust system when the piston is near BDC. Opening the exhaust valve before the piston reaches BDC, reduces the work obtained during the power stroke but is required because of the finite time needed for exhaust blow down.

Fourth stroke: Exhaust stroke

By the time the piston reaches BDC during the power stroke, the cylinder is still full of exhaust gases. With the exhaust valve remaining open, the piston now travels upward to make the gases move out of the cylinder into the exhaust system, leaving only that amount of exhaust gasses which are trapped in the clearance volume when the piston reaches TDC. Near the end of exhaust stroke, the intake valve starts to open, so that it is fully open by TDC to start the new intake stroke in the next cycle. Near TDC exhaust valve starts to close and finally is fully closed sometime at TDC. This period when both intake valve and exhaust valve are open is called valve overlap.

Four stroke Compression Ignition (Diesel) engine

· First stroke: Intake stroke: The same as the intake stroke in the SI engine with one major difference: no fuel is added to the incoming air.

· Second stroke: Compression stroke: The same as in an SI engine except that only air is compressed and compression is to higher pressures and temperature. Late in the compression strike fuel is injected directly into the combustion chamber when it mixes with very hot air. This causes the fuel to evaporate and self ignite, causing combustion to start. Combustion is fully developed by TDC and continues at about constant pressure until the fuel injection is complete and the piston has started towards BDC.

· Third stroke: Power stroke: The power stroke continues as combustion ends and the piston travels towards BDC. Exhaust Blowdown is same as with an SI engine.

· Fourth stroke: Exhaust strike: Same as with an SI engine

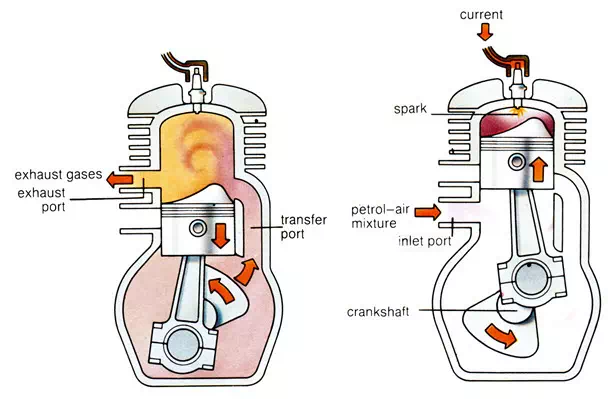

Two stroke Spark Ignition (Petrol) engine

Instead of inlet and exhaust valves available in Four-Stroke spark ignition (petrol) and compression ignition (diesel) engines, Two-Stroke engines are equipped with inlet and outlet ports which are opened and closed with the reciprocating movement of piston only. In these engines the complete cycle of suction, compression, power and exhaust is performed with two strokes i.e one revolution of the crankshaft.

In two stroke engines, the air fuel mixture is entered from the carburetor through the inlet port at the bottom when the piston starts moving upward. The air fuel mixture is compressed at the same time during the same stroke, hence suction and compression are being performed simultaneously. When the piston reaches just at TDC, the combustion takes place and piston generates movement to the crankshaft. As the piston moves downward with power stroke, it compresses the mixture in crankcase to move into cylinder through the transfer port which pushes the out the burnt/exhaust gases to move out from the exhaust port. And at the same time, new charge (air fuel mixture) start entering through the inlet port, this process is also know as cross-flow scavenging. In this way, all four strokes of engine cycle are completed in the two strokes (one upward and one downward movement of piston) only.