TYPES OF ENGINES LUBRICATION SYSTEM

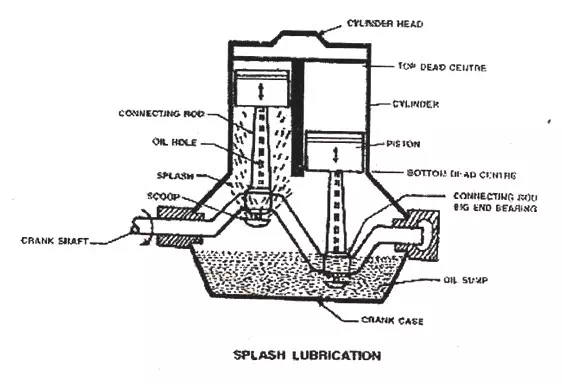

Splash lubrication system

In splash lubrication system the lubrication oil is picked from the oil sump or a pan by a dipper provided at the bottom of the connecting rod for piston in each cylinder. The connecting rod picks the oil from the bottom and moves upward to the engine components. Some oils is also reached to different components like bearings, connecting rod through splash as mechanical turbulence is generated in the crankcase by the moving components which further makes the oil spread in the form of mist in the crankcase. This mist further reaches to other engine components like piston, piston pin and cylinder walls. The camshaft and valve mechanism is also lubricated by the oil. Although the splash type lubrication system is still being used in the engines these days but its usage has been found to be limited to small or single cylinder engines as the splash only is not sufficient to make oil to reach all critical components of the engine.

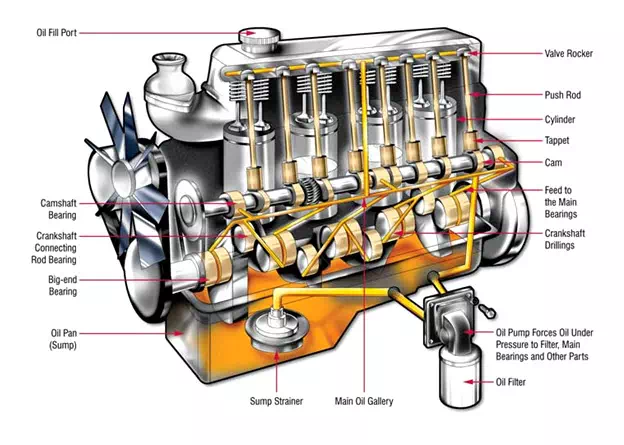

Force feed lubrication system

As splash system has limitations to lubricate all the critical components in an engine, force feed system is used to generate additional pressure to ensure oil reaching to all essential and desired components for lubrication purposes. Generally, a gear type pump driven by the camshaft generates the pressure in oil to move from the crankcase to crankshaft, connecting rod, bearings pistons and valves. S the lubricating oil is supplied to the engine components under pressure, hence the reach of oil is enhanced to lubricate the remote and farthest points. This helps in efficient lubrication of engine components and hence in achieving better engine performance.