Weight and Strength

HOW DOES AN AIRCRAFT BALANCE WEIGHT AND

STRENGTH?

Finding a safe

compromise between low weight and high strength is critical when creating an

aircraft. Aircraft structures must be light yet strong and stiff enough to

resist the various forces acting on an airplane during flight. They must also

be durable enough to withstand these forces over the airplane’s entire life

span.

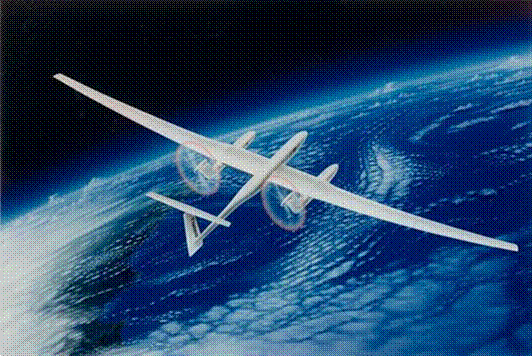

Wings don’t have

to be heavy to be strong. This pilotless aircraft called Theseus was built for

high-altitude research flights. The skin consists of a honeycomb material

sandwiched between layers of woven carbon fibers embedded

in a plastic resin. Similar stiff, lightweight materials are used on other

types of aircraft.

Credit:

Aurora Flight Sciences, Manassas, Virginia

Any aircraft

design is a carefully planned compromise in which many competing factors are

traded against one another: payload capacity, cost, range, speed, fuel economy,

durability, noise levels, required runway length, and many others. The function

of an aircraft—whether an airliner or a fighter, a business jet or a private

airplane—is the major influence in balancing these factors. The best design

typically provides maximum performance at the lowest weight.