Ducted fan

A ducted

fan is a propulsion arrangement whereby a mechanical fan, which is a type of propeller, is mounted within a cylindrical shroud or duct. The duct reduces losses in thrust from the tips of the props, and varying the cross-section

of the duct allows the designer to advantageously affect the velocity and

pressure of the airflow according to Bernoulli's

Principle.

Ducted fan propulsion is used in aircraft, airships, airboats, hovercraft and fan packs.Ducted fans normally have

more and shorter blades than propellers and thus can operate at higher

rotational speeds.

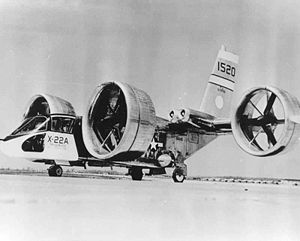

Bell X-22 on

the tarmac

Applications

Ducted fans on

an airship or dirigible

In aircraft

applications, the operating speed of an unshrouded propeller is limited since

tip speeds approach the sound

barrier at

lower speeds than an equivalent ducted fan. The most common ducted fan

arrangement used in full-sized aircraft is a turbofan engine, where the power to turn the fan

is provided by a gas

turbine.

Turbofan engines are used on nearly all airliners, fighters, and bombers. However, a ducted fan may be powered by any

source of shaft power such as a reciprocating

engine, Wankel engine, or electric motor. A kind of ducted fan,

known as a fantail or by the trademark name Fenestron, is also used to

replace tail rotors on helicopters. Ducted fans usually have an odd number of

blades to prevent resonance in the duct.

A Sailor checks

the ducted propeller of a Landing

Craft Air Cushion (LCAC)

Hovercraft

Ducted fans

are favored in VTOL aircraft such as the Lockheed Martin F-35

Lightning II,

and other low-speed designs such as hovercraft for their higher

thrust-to-weight ratio.

In some cases, a shrouded rotor can be 94% more efficient than an open rotor. The improved performance is mainly because the outward flow is less contracted and thus carries more kinetic energy.

Among model aircraft hobbyists, the ducted

fan is popular with builders of high-performance radio controlled model aircraft. Internal-combustion glow engines combined with

ducted-fan units were the first achievable means of modeling a

scaled-size jet aircraft. Despite the introduction of model-scale turbojet engines, electric-powered ducted fans

remain popular on smaller, lower-cost model aircraft. Some electric-powered

ducted fan airplanes can reach speeds of more than 320km/h (200mph).

Advantages

The Martin Jetpack, a personal aircraft

powered by ducted fans

● By reducing propeller blade

tip losses, the ducted fan is more efficient in producing thrust than a

conventional propeller of similar diameter, especially at low speed and high

static thrust level (airships, hovercraft).

● By sizing the ductwork

appropriately, the designer can adjust the fan to allow it to operate more

efficiently at higher air speeds than a propeller would.

● For the same static thrust,

a ducted fan has a smaller diameter than a free propeller, allowing smaller

gear.

● Ducted fans are quieter

than propellers: they shield the blade noise, and reduce the tip speed and

intensity of the tip

vortices both

of which contribute to noise production.

● Ducted fans can allow for a

limited amount of thrust

vectoring,

something normal propellers are not well suited for. This allows them to be

used instead of tiltrotors in some applications.

● Ducted fans offer enhanced

safety on the ground.

Disadvantages

● Less efficient than a

propeller at cruise (at lower thrust level).

● Good efficiency requires

very small clearances between the blade tips and the duct.

● Requires high RPM and minimal vibration.

● Complex duct design, and

weight increase even if constructed from advanced composites.

● At high angle of attack, parts of the duct will

stall and produce aerodynamic

drag.