Contra-rotating propeller

Contra-rotating

propellers of a modified North American P-51 Mustang fitted with a Rolls-Royce Griffon engine.

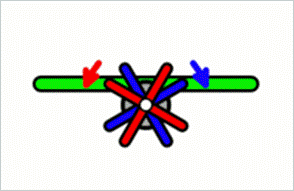

A

contra-rotating propeller or contra-prop places two counter-rotating propellers

on concentric drive shafts so that one sits immediately 'downstream' of the

other propeller. This provides the benefits of counter-rotating propellers for

a single powerplant. The forward propeller

provides the majority of the thrust, while the rear propeller also recovers

energy lost in the swirling motion of the air in the propeller slipstream.

Contra-rotation also increases the ability of a propeller to absorb power from

a given engine, without increasing propeller diameter. However the added cost,

complexity, weight and noise of the system rarely make it worthwhile and it is

only used on high-performance types where ultimate performance is more

important than efficiency.

Not to be

confused with counter-rotating

propellers.

For

contra-rotating marine propellers, helicopter rotors and turbine fan blades,

see Contra-rotating.

Contra-rotating

propellers

Contra-rotating

propellers on number 38, the P 51XR Mustang N6WJ Precious Metal Reno Air Race

2014

Aircraft

equipped with contra-rotating propellers, also referred to as CRP, coaxial

contra-rotating propellers, or high-speed propellers, apply the

maximum power of usually a single piston or turboprop engine to drive two coaxial propellers in contra-rotation (rotation about the

same axis in opposite directions). Two propellers are arranged one behind the

other, and power is transferred from the engine via a planetary gear or spur gear transmission. Contra-rotating

propellers should not be confused with counter-rotating propellers—airscrews on separate shafts turning in

opposite directions.

Operation

When airspeed is

low, the mass of the air flowing

through the propeller disk (thrust) causes a significant

amount of tangential or rotational air

flow to be created by the spinning blades. The energy of this tangential air

flow is wasted in a single-propeller design. To use this wasted effort the

placement of a second propeller behind the first takes advantage of the

disturbed airflow. The tangential air flow also causes handling problems at low

speed as the air strikes the vertical

stabilizer,

causing the aircraft to yaw left or right, depending on the direction of

propeller rotation.

If it is well

designed, a contra-rotating propeller will have no rotational air flow, pushing

a maximum amount of air uniformly through the propeller disk, resulting in high

performance and low induced energy loss. It also serves to counter the asymmetrical torque effect of a conventional propeller

(see P-factor). Some contra-rotating

systems were designed to be used at take off for

maximum power and efficiency under such conditions, and allowing one of the

propellers to be disabled during cruise to extend flight time.

Advantages and disadvantages

The torque on

the aircraft from a pair of contra-rotating propellers effectively cancels out.

Contra-rotating propellers have been found to be between 6% and 16% more efficient than normal propellers.

However they can be very noisy, with increases in noise in the axial (forward and aft) direction of up to 30 dB, and tangentially 10 dB. Most of this extra noise can be found in the higher frequencies. These substantial noise problems limit commercial applications. One possibility is to enclose the contra-rotating propellers in a shroud. It is also helpful if the two propellers have a different number of blades (e.g. four blades on the forward propeller and five on the aft).

The efficiency

of a contra-rotating prop is somewhat offset by its mechanical complexity and

the added weight of this gearing that makes the aircraft heavier, thus some

performance is sacrificed to carry it. Nonetheless, coaxial contra-rotating

propellers and rotors have been used in

several military

aircraft, such

as the Tupolev Tu-95

"Bear".

They are also being examined for use in airliners.

Use in aircraft

While several nations experimented with contra-rotating propellers in aircraft, only the United Kingdom and Soviet Union produced them in large numbers. The first aircraft to be fitted with a contra-rotating propeller to fly though was in the US when two inventors from Ft Worth, Texas tested the concept on an aircraft.

United Kingdom

Contra-rotating

propellers of a Spitfire Mk XIX

A contra-rotating propeller was patented by F. W. Lanchester in 1909.

Some of the more

successful British aircraft with contra-rotating propellers are the Avro Shackleton, powered by the Rolls-Royce Griffon engine, and the Fairey Gannet, which used the Double Mamba Mk.101 engine. In the Double

Mamba two separate power sections drove one propeller each, allowing one power

section (engine) to be shut down in flight, increasing endurance.

Another naval

aircraft, the Westland

Wyvern had

contra-rotating propellers.

Later variants

of the Supermarine Spitfire and Seafire used the Griffon with contra-rotating props.

In the Spitfire/Seafire and Shackleton's case

the primary reason for using contra-rotating propellers was so as to increase

the propeller blade-area, and hence absorb greater engine power, within a propeller

diameter limited by the height of the aircraft's undercarriage. The Short Sturgeon used 2 Merlin 140s

with contra-rotating propellers.

The Bristol Brabazon prototype airliner used eight Bristol Centaurus engines driving four pairs of contra-rotating propellers, each engine driving a single propeller.

The

post-war SARO Princess prototype flying

boat airliner also had contra-rotating propellers.

USSR, Russia and Ukraine

One of the

quartet of contra-rotating propellers on a Tu-95 Russian strategic bomber

In the 1950s,

the Soviet Union developed the Kuznetsov NK-12 turboprop. It drives an 8-blade

contra-rotating propeller and, at 15,000 shp, it

is the most powerful turboprop in the world. Four NK-12 engines power the Tupolev Tu-95 Bear, the only turboprop bomber

to enter service, as well as one of the fastest propeller-driven aircraft. The Tu-114, an airliner derivative of the Tu-95, holds

the world speed record for propeller aircraft. The Tu-95 was also the first

Soviet bomber to have intercontinental range. The Tu-126 AEW aircraft and Tu-142maritime patrol aircraft are two more NK-12

powered designs derived from the Tu-95.

The NK-12 engine

powers another well-known Soviet aircraft, the Antonov An-22 Antheus, a

heavy-lift cargo aircraft. At the time of its introduction, the An-22 was the

largest aircraft in the world and is still by far the world's largest

turboprop-powered aircraft. From the 1960s through the 1970s, it set several

world records in the categories of maximum payload-to-height ratio and maximum

payload lifted to altitude.

Of lesser note

is the use of the NK-12 engine in the A-90 Orlyonok, a mid-size Soviet ekranoplan. The A-90 uses one NK-12

engine mounted atop its T-tail, along with two turbojets nestled in its nose.

In 1994, Antonov produced the An-70, a heavy transport aircraft. It is powered by

four Progress D-27 propfan engines driving

contra-rotating propellers. The characteristics of the D-27 engine and its

propeller make it a propfan, a hybrid between a

turbofan engine and a turboprop engine.

United States

Douglas XB-42 Mixmaster

General Motors

P-75 Eagle

The U.S. worked

with several prototypes, including the Northrop XB-35, XB-42

Mixmaster,

the Douglas XTB2D Skypirate, the Curtiss XBTC, the A2J Super Savage, the Boeing XF8B, the XP-56 Black Bullet, the Fisher

P-75 Eagle and

the tail-sitting Convair XFY "Pogo" and Lockheed XFV "Salmon" VTOL fighters and the Hughes XF-11 reconnaissance plane. However, both piston-engined and turboprop-powered propeller-driven

aircraft were reaching their zenith and new technological developments such as

the advent of the pure turbojet and turbofanengines, both without propellers, meant that

the designs were quickly eclipsed.

Ultralight applications

An Austrian company, Sun Flightcraft, distributes a contra-rotating gearbox for use on Rotax 503 and 582 engines on ultralight and microlight aircraft. The Coax-P was developed by Hans Neudorfer of NeuraJet and allows powered hang-gliders and parachutes to develop 15 to 20 percent more power while reducing torque moments. The manufacturer also reports reduced noise levels from dual contra-rotating props using the Coax-P gearbox.

Use in water

Torpedoes such as the Bliss-Leavitt torpedo have commonly used

contra-rotating propellers to give the maximum possible speed within a limited

diameter as well as counteracting the torque that would otherwise tend to cause

the torpedo to rotate around its own longitudinal axis.

Recreational

Boating: in 1982 Volvo

Penta introduced

a contra-rotating boat propeller branded DuoProp.

The patented device has been marketed since.