New approaches

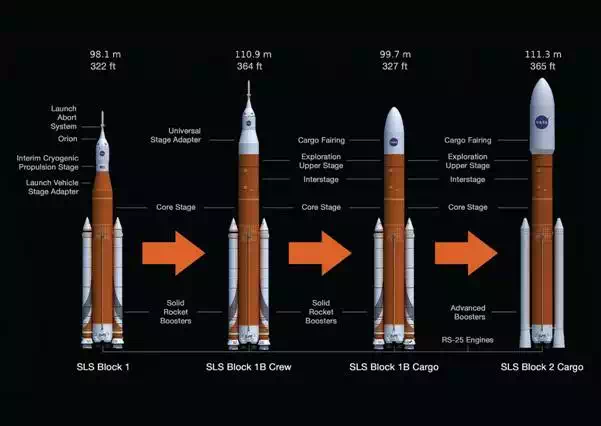

After the demise of the Space Shuttle programme in 2011, the US’ capability of launching humans into space was heavily restricted. NASA is currently working on a new Space Launch System (SLS), the aim of which is to extend NASA’s range beyond low-Earth orbit and further out into the Solar system. Although the SLS is being designed and assembled by NASA, other partners such as Boeing, United Launch Alliance, Orbital ATK and Aerojet Rocketdyne are co-developing individual components. The SLS specification as it stands would make it the most powerful rocket in history and the SLS is therefore being developed in two stages (reminiscent of the Saturn IB and Saturn V rocket). First, a rocket with a payload capability of 70 metric tons (175,000 lb) is being developed from components of previous rockets. The goal of this heritage SLS is to conduct two lunar flybys with the Orion spacecraft, one unmanned and the other with a crew. Second, a more advanced version of the SLS with a payload capability of 130 metric tons (290,000 lb) to low-earth orbit, about the same payload capacity and 20% more thrust than the Saturn V rocket, is deemed to carry scientific equipment, cargo and the manned Orion capsule into deep space. The first flight for an unmanned Orion capsule on a trip around the moon is planned for 2018, while manned missions are expected by 2021-2023. By 2026 NASA plans to send a manned Orion capsule to an asteroid previously placed into lunar orbit by a robotic “capture-and-place” mission.

NASA’s upgrade plan for the SLS

However, with the commercialisation of space travel new incumbents are now working on even more daunting goals. The SpaceX Falcon 9 rocket has proven to be a very reliable launch system (with a current success rate of 20 out of 22 launches). Furthemore, SpaceX was the first private company to successfully launch and recover an orbital spacecraft, the Dragon capsule, which regularly supplies the ISS with supplies and new scientific equipment. Currently, the US relies on the Russian Soyuz rocket to bring astronauts to the ISS but in the near future manned missions are planned with the Dragon capsule. The Falcon 9 rocket is a two-stage-to-orbit launch vehicle comprised of nice SpaceX Merlin rocket engines fuelled by liquid oxygen and kerosene with a payload capacity of 13 metric tons (29,000 lb) into low-Earth orbit. There have been three versions of the Falcon 9, v1.0 (retired), v1.1 (retired) and most recently the partially reusable full thrust version, which on December 22, 2015 used propulsive recovery to land the first stage safely in Cape Canaveral. To date, efforts are being made to extend the landing capabilities from land to sea barges. Furthermore, the Falcon Heavy with 27 Merlin engines (a central Falcon 9 rocket with two Falcon 9 first stages strapped to the sides) is expected to extend SpaceX’s lifting capacity to 53 metric tons into low-Earth orbit, making it the second most powerful rocket in use after NASA’s SLS. First flights of the Falcon Heavy are expected for late this year (2016). Of course, the ultimate goal of SpaceX’s CEO Elon Musk, is to make humans a multi planetary species, and to achieve this he is planning to send a colony of a million humans to Mars via the Mars Colonial Transporter, a space launch system of reusable rocket engines, launch vehicles and space capsules. SpaceX’s Falcon 9 rocket already has the lowest launch costs at $60 million per launch, but reliable re-usability should bring these costs down over the next decade such that a flight ticket to Mars could become enticing for at least a million of the richest people on Earth (or perhaps we could sell spots on “Mars – A Reality TV show“).

When will this become reality?

Blue Origin, the rocket company of Amazon founder Jeff Bezos, is taking a similar approach of vertical takeoff and landing to re-usability and lower launch costs. The company is on an incremental trajectory to extend its capabilities from suborbital to orbital flight, led by its motto “Gradatim Ferocity” (latin for step by step, ferociously). Blue Origin’s New Shepard rocket underwent its first test flight in April 2015. In November 2015 the rocket landed successfully after a suborbital flight to 100 km (330,000 ft) altitude and this was extended to 101 km (333,000 ft) in January 2016. Blue hopes to extend its capabilities to human spaceflight by 2018.

Reaction Engines is a British aerospace company conducting research into space propulsion systems focused on the Skylon reusable single-stage-to-orbit spaceplane. The Skylon would be powered by the SABRE engine, a rocket-based combined cycle, i.e. a combination of an air-breathing jet engine and a rocket engine, whereby both engines share the same flow path, reusable for about 200 flights. Reaction Engines believes that with this system the cost of carrying one kg (2.2 lb) of payload into low-earth orbit can be reduced from the $1,500 today (early 2016) to around $900. The hydrogen-fuelled Skylon is designed to take-off from a purpose built runway and accelerate to Mach 5 at 28.5 km (85,500 feet) altitude using the atmosphere’s oxygen as oxidiser. This air-breathing part of the SABRE engine works on the same principles as a jet engine. A turbo-compressor is used to raise the pressure ratio of the incoming atmospheric air, which is pre-staged by a pre-cooler to cool the hot air impinging on the engine at hypersonic speeds. The compressed air is fed into a rocket combustion chamber where it is ignited with liquid hydrogen. As in a standard jet engine, a high pressure ratio is crucial to pack as much of the oxidiser into the combustion chamber and increase the thrust of the engine. As the natural source of oxygen runs out at high altitude, the engines switch to the internally stored liquid oxygen supplies, transforming the engine into a closed-cycle rocket and propelling the Skylon spacecraft into orbit. The theoretical advantages of the SABRE engine is its high fuel efficiency and low mass, which facilitate the single-stage-to-orbit approach. Reminiscent of the Shuttle, after deploying the its payload of up to 15 tons (38,000 lb), the Skylon spacecraft would then re-enter the atmosphere protected by a heat shield and land on a runway. The first ground tests of the SABRE engine are planned for 2019 and first unmanned test flights are expected for 2025.

SABRE rocket engine

Sierra Nevada Corporation is working alongside NASA to develop the Dream Chaser spacecraft for transporting cargo and up to seven people to low-earth orbit. The Dream Chaser is designed to launch on top of the Atlas V rocket (in place of the nose cone) and land conventionally by gliding onto a runway. The Dream Chaser looks a lot like a smaller version of the Space Shuttle, so intuitively one would expect the same cost inefficiencies as for the Shuttle. However, the engineers at Sierra Nevada say that two changes have been made to the Dream Chaser that should reduce the maintenance costs. First, the thrusters used for attitude control are ethanol-based, and therefore not toxic and a lot less volatile than the hydrazine-based thursters used by the Shuttle. This should allow maintenance of the Dream Chaser to ensue immediately after landing and reduce the time between flights. Second, the thermal protection system is based on an ablative tile that can survive multiple flights and can be replaced in larger groups rather than tile-by-tile. The Dream Chaser is planned to undergo orbital test flights in November 2016.

The Dream Chaser

Finally, the New Zealand-based firm Rocket Lab is developing the all-carbon composite liquid-fuelled Electron rocket with a payload capability to low-Earth orbit of 110 kg (240 lb). Thus, Rocket Lab is focusing on high-frequency rocket launches to transport low-mass payload, e.g. nano satellites, into orbit. The goal of Rocket Lab is to make access to space frequent and affordable such that the rapidly evolving small-scale satellites that provide us with scientific measurements and high-speed internet can be launched reliably and quickly. The Rocket Lab system is designed to cost $5 million per launch at 100 launches a year and use less fuel than a flight on a Boeing 737 from San Francisco to Los Angeles. A special challenge that Rocket Lab is facing is the development of the all-carbon composite liquid oxygen tanks to provide the mass efficiency required for this high fuel efficiency. To date the containment of cryogenic (super cold) liquid fuels, such as liquid hydrogen and liquid oxygen, is still the domain of metallic alloys. Concerns still exist about potential leaks due to micro cracks developing in the resin of the composite at cryogenic temperatures. In composites, there is a mismatch between the thermal expansion coefficients of the reinforcing fibre and the resin, which induces thermal stresses as the composite is cooled to cryogenic temperatures from its high temperature/high pressure curing process. The temperature and pressure cycles during the liquid oxygen/hydrogen fill-and-drain procedures then induces extra fatigue loading that can lead to cracks permeating through the structure through which hydrogen or oxygen molecules can easily pass. This leaking process poses a real problem for explosion.