Jet Engine Design: Afterburning

A very important parameter when designing jet engines is specific power – the amount of power output divided by the mass of the engine. In general, a good heuristic to keep in mind when designing anything that moves is that maximising the power output per unit mass leads to a more efficient design. Afterburning is an exception to this rule. Yes, afterburning provides more thrust and therefore provides more bang for every gram of jet engine, but it is terribly fuel inefficient.

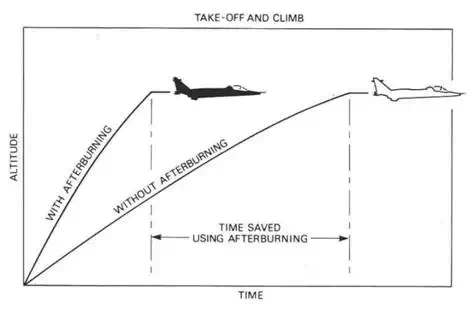

Afterburning, sometimes also called reheat, is a means of increasing the thrust of a jet engine in order to improve aircraft take-off and climb performance, to accelerate beyond the sound barrier, or in a military setting, for improved combat performance. Of course, we could simply increase the thrust by building a bigger and more powerful engine, but this naturally leads to a greater frontal area that impedes the oncoming flow, and therefore increases drag. Even though afterburning is incredibly fuel-inefficient, it is the best solution for enabling massive amounts of additional thrust at the switch of a button. This means an engine can be run in two modes – a fuel efficient, low thrust configuration and a fuel-inefficient, high-thrust configuration.

Effect of afterburning during take-off and climbing [1]

From conservation of momentum

we know that the thrust of a jet engine is governed by the mass flow

rate, ![]() , and the difference between the entry and exit

velocities of air into,

, and the difference between the entry and exit

velocities of air into, ![]() , and out of,

, and out of, ![]() , the jet engine.

, the jet engine.

![]()

For a fixed airspeed ![]() , this means that the level of thrust depends on both the exit jet

velocity of the gases and the mass of air flowing through the engine per

second. So to produce high levels of thrust we can either accelerate the

exhaust gases to a greater velocity, or just increase the amount of air that is

being sucked into the engine. Early turbojets attempted to maximise the exit

jet velocity in order to create more and more thrust. The downside of this

approach is that it decreases the efficiency of the engine. The propulsive or Froude efficiency

, this means that the level of thrust depends on both the exit jet

velocity of the gases and the mass of air flowing through the engine per

second. So to produce high levels of thrust we can either accelerate the

exhaust gases to a greater velocity, or just increase the amount of air that is

being sucked into the engine. Early turbojets attempted to maximise the exit

jet velocity in order to create more and more thrust. The downside of this

approach is that it decreases the efficiency of the engine. The propulsive or Froude efficiency ![]() of a

jet engine is defined by the power output divided by the rate of change of

kinetic energy of the air. The kinetic energy of the air represents the power

input to the system. The power output P is the product of

force output i.e. the thrust F and the resulting air speed

of a

jet engine is defined by the power output divided by the rate of change of

kinetic energy of the air. The kinetic energy of the air represents the power

input to the system. The power output P is the product of

force output i.e. the thrust F and the resulting air speed

![]() . Although

this is an approximation, this equation summarises the essential terms that

define aircraft propulsion. So, power output is

. Although

this is an approximation, this equation summarises the essential terms that

define aircraft propulsion. So, power output is

![]()

and the rate of change in kinetic energy is

![]()

such that the propulsive efficiency is

![]()

This means that for

a fixed airspeed ![]() , the efficiency can be increased by reducing the jet

exit velocity

, the efficiency can be increased by reducing the jet

exit velocity ![]() . However, decreasing the jet exit velocity

. However, decreasing the jet exit velocity ![]() decreases

the thrust unless the mass flow rate

decreases

the thrust unless the mass flow rate ![]() is increased as well. Note that the advantage of increasing

the mass flow rate is that it does not have an effect on the propulsive

efficiency.

is increased as well. Note that the advantage of increasing

the mass flow rate is that it does not have an effect on the propulsive

efficiency.

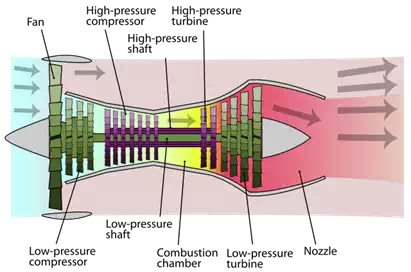

Schematic Diagram of Turbofan Engine (Photo credit: Wikipedia)

High bypass-ratio turbofan engines, which are the most common in modern airliners, are designed around this second principle – the big fan at the front sucks in tons of air, but because this flow bypasses the combustion chamber, it is not accelerated to a high exit velocity. The advantages of this design is that increasing the bypass ratio yields better fuel efficiency which means that turbofans can be operated over long periods (great for long-haul commercial passenger flights).

The downside, of course, is increased size and induced drag, which is a nightmare for nimble fighter aircraft. In fighter aircraft you want a small and compact engine that provides tons of thrust. Fuel efficiency is typically of secondary concern. Therefore, an afterburner naturally addresses the first principle we discussed above – accelerating the exhaust gases to higher velocity. This generally means that we can shrink the size of the engine and decrease the bypass ratio to provide better aerodynamic performance.

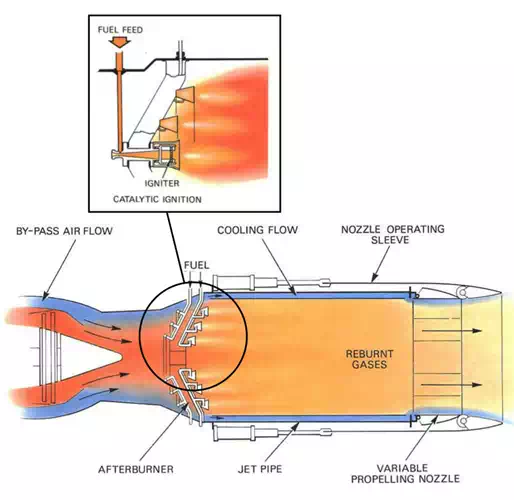

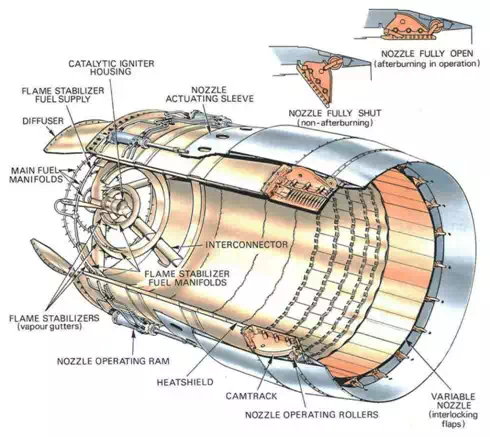

Schematic of afterburning components and functionality at the tail end of a jet engine [1]

As shown in the figure above, afterburning is achieved by injecting extra fuel into the hot exhaust gases that are being expelled by the turbine stage. The gas inside the jet engine is highest just before entering the turbine (just after combustion), and this turbine entry temperature is often the limiting design driver of the entire jet engine. Today, the turbine entry temperature is actually greater than the melting point of the metal used to make the turbine blades, but clever single-casting manufacturing methods and intricate cooling ducts inside the turbine blades guarantee that the blades do not creep excessively. To further limit the turbine entry temperature the combustion just prior to the turbine stage typically occurs at an oxygen-rich ratio such that sufficient oxygen is present in the hot gases flowing through and exiting the turbine. The hot jet exiting the turbine contains sufficient uncombusted oxygen that spraying more fuel into the jet pipe, and igniting the ensuing fuel-oxygen mix with a little spark raises the temperature to about 1700°C, and the related increase in the pressure forces the gases through the exhaust nozzle at increased velocity.

The hot jet from the turbine flows into the jet pipe at a velocity of around 250 m/s to 400 m/s, and this velocity is far too high to guarantee stable combustion in the jet pipe. Just prior to the jet pipe, the cross-sectional area of the exit portion to the turbine increases to diffuse the flow to lower velocities. However, because the standard injection rate of kerosene at a good fuel-to-oxygen mixture is only around 1-2 m/s, the kerosene would be rapidly blown away even by the diffused jet stream. To prevent this a vapour gutter is placed just prior to the fuel injection nozzles that spins the jet into turbulent eddie currents, thereby further slowing down the hot turbine exhaust gases and allowing for a better mixture of fuel and jet stream. A common misconception is that due to the high temperature of the gases exiting the turbine (around 700°C), the fuel-oxygen mixture in the jet pipe would combust spontaneously. Cooler combustion flames can develop at these temperatures, but because of the atmospheric pressure differences between ground level and altitude, a design that spontaneously combusts at ground level would never do so at altitude. To guarantee a stable and smooth reaction over a wide range of mixture ratios and flying altitudes, a high-intensity spark is needed.

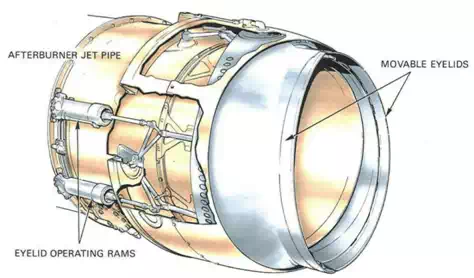

Two-position nozzle [1]

Variable-area nozzle [1]

To allow the jet to operate without afterburning, the jet pipe is fitted with a two-position or a variable-area propelling nozzle as shown above. When afterburning is not being used, the nozzle remains in its closed configuration, but opens when afterburning is initiated to increase the exit area and prevent pressure from building up in the jet pipe that can adversely affect the operation of the turbine. A two-position nozzle has two “eyelids” that can be moved irrespective of the other in order to open or close the nozzle area. A variable-area nozzle consists of multiple flaps situated side-by-side in a ring arrangement around the exit nozzle and hinged to the outer casing. The nozzles can rotate into or out of the flow by rotating rollers that are actuated by a camtrack and a linear actuator (operating ram). When afterburning is initiated, a fuel control unit determines the correct amount of fuel to flow into the jet pipe to provide the correct balance between increased jet pipe pressure and the pressure ratio across the turbine. The pressure ratio across the turbine is crucial for efficient operation of the jet engine as it provides the energy to operate the compressor stages. Therefore, the control system can automatically vary the nozzle exit area in order to maintain the correct pressure ratio across the turbine – the higher the degree of afterburning, the greater the build-up of pressure in the jet pipe, and thus, the greater the required nozzle area to reduce the load on the turbine.

Thrust and fuel consumption

The increase in thrust is a function of the increase in jet pipe temperature as a result of afterburning. For a perfectly efficient system, the relationship between the temperature ratio before and after fuel is burnt, and the thrust increase is nearly linear in the typical operating range with temperature ratios of 1.4 to 2.2. Within this range we can expect a 40% increase in thrust for a doubling of the temperature in the jet pipe. Thus, if afterburning raises the jet pipe temperature from 700°C (973 K) to 1500°C (1773 K) this results in a thrust increase of around 36%.

![]()

In a static test bed, thrust increases of up to 70% can be obtained at the top end, and at high forward speeds, several times this can be achieved. The lower the temperature exiting the turbine and the greater the extent of uncombusted oxygen, the greater the temperature increase in the jet pipe due to afterburning.

As is to be expected, afterburning naturally incurs a fuel consumption penalty, and this is why afterburning is typically constrained to short bursts. The aim of the compressor in a classic jet engine is to raise the pressure of the incoming air to the optimal pressure for efficient combustion. After expansion by the turbine stage, the gases are at a lower degree of compression, and therefore the fuel is not burnt as efficiently as in the combustion chamber between compressor and turbine. For a 70% increase in thrust the fuel consumption can easily double, but of course this increased fuel consumption is balanced by an improved performance in terms of take-off and climb. This means that the increased fuel consumption is balanced by the time saved to cover a desired distance or operating manoeuvre.