Total Air Temperature Measurement

Air temperature is a valuable parameter that many performance monitoring and control variables depend on. During flight, static air temperature changes continuously and accurate measurement presents challenges. Below 0.2 Mach, a simple resistance-type or bimetallic temperature gauge can provide relatively accurate air temperature information. At faster speeds, friction, the airís compressibility, and boundary layer behavior make accurate temperature capture more complex. Total air temperature (TAT) is the static air temperature plus any rise in temperature caused by the highspeed movement of the aircraft through the air. The increase in temperature is known as ram rise. TAT-sensing probes are constructed specifically to accurately capture this value and transmit signals for cockpit indication, as well as for use in various engine and aircraft systems.

Simple TAT systems include a sensor and an indicator with a built-in resistance balance circuit. Air flow through the sensor is designed so that air with the precise temperature impacts a platinum alloy resistance element. The sensor is engineered to capture temperature variations in terms of varying the resistance of the element. When placed in the bridge circuit, the indicator pointer moves in response to the imbalance caused by the variable resistor.

More complex systems use signal correction technology and amplified signals sent to a servo motor to adjust the indicator in the cockpit. These systems include closely regulated power supply and failure monitoring. They often use numeric drum type readouts, but can also be sent to an LCD driver to illuminate LCD displays. Many LCD displays are multifunctional, capable of displaying static air temperature and true airspeed. In fully digital systems, the correction signals are input into the ADC. There, they can be manipulated appropriately for cockpit display or for whichever system requires temperature information.

Different cockpit TAT displays.

TAT sensor/probe design is complicated by the potential of ice forming during icing conditions. Left unheated, a probe may cease to function properly. The inclusion of a heating element threatens accurate data collection. Heating the probe must not affect the resistance of the sensor element.

Close attention is paid to airflow and materials conductivity during the design phase. Some TAT sensors channel bleed air through the units to affect the flow of outside air, so that it flows directly onto the platinum sensor without gaining added energy from the probe heater.

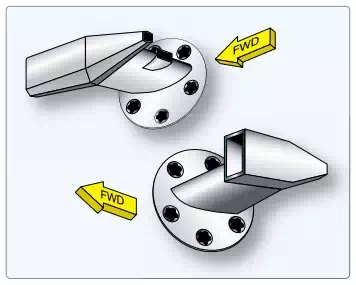

Total air temperature (TAT) probes.