Pitot-Static Systems

Some of the most important flight instruments derive their indications from measuring air pressure. Gathering and distributing various air pressures for flight instrumentation is the function of the pitot-static system.

Pitot Tubes and Static Vents

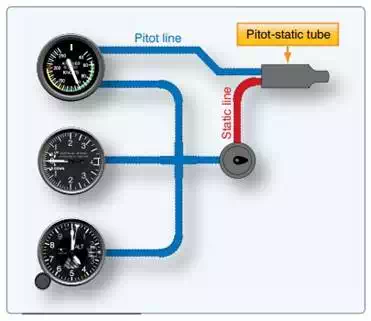

On simple aircraft, this may consist of a pitot-static system head or pitot tube with impact and static air pressure ports and leak-free tubing connecting these air pressure pickup points to the instruments that require the air for their indications. The altimeter, airspeed indicator, and vertical speed indicator are the three most common pitot-static instruments. Figure illustrates a simple pitot-static system connected to these three instruments.

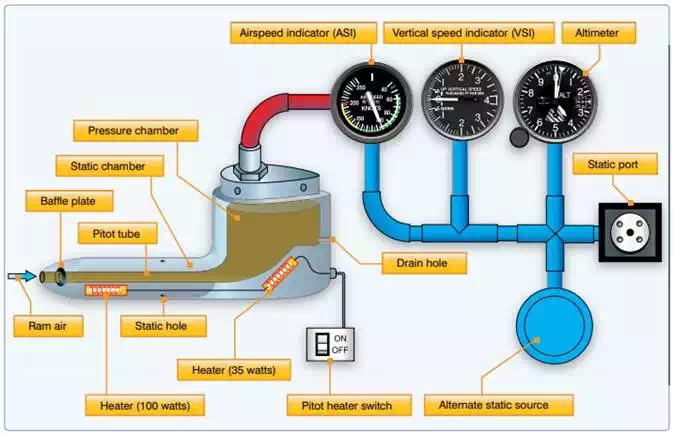

A pitot tube is shown in Figure 10-23. It is open and faces into the airstream to receive the full force of the impact air pressure as the aircraft moves forward. This air passes through a baffled plate designed to protect the system from moisture and dirt entering the tube. Below the baffle, a drain hole is provided, allowing moisture to escape. The ram air is directed aft to a chamber in the shark fin of the assembly. An upright tube, or riser, leads this pressurized air out of the pitot assemble to the airspeed indicator.

A typical pitot-static system head, or pitot tube, collects ram air and static pressure for use by the flight instruments.

Many pitot-static tube heads contain heating elements to prevent icing during flight. The pilot can send electric current to the element with a switch in the cockpit when ice-forming conditions exist. Often, this switch is wired through the ignition switch so that when the aircraft is shut down, a pitot tube heater inadvertently left on does not continue to draw current and drain the battery. Caution should be exercised when near the pitot tube, as these heating elements make the tube too hot to be touched without receiving a burn.

The pitot-static tube is mounted on the outside of the aircraft at a point where the air is least likely to be turbulent. It is pointed in a forward direction parallel to the aircraft’s line of flight. The location may vary. Some are on the nose of the fuselage and others may be located on a wing. A few may even be found on the empennage. Various designs exist but the function remains the same, to capture impact air pressure and static air pressure and direct them to the proper instruments.

Pitot-static system heads, or pitot tubes, can be of various designs and locations on airframes

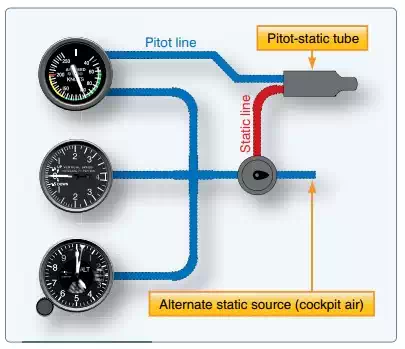

Most aircraft equipped with a pitot-static tube have an alternate source of static air pressure provided for emergency use. The pilot may select the alternate with a switch in the cockpit should it appear the flight instruments are not providing accurate indications. On low-flying unpressurized aircraft, the alternate static source may simply be air from the cabin.On pressurized aircraft, cabin air pressure may be significantly different than the outside ambient air pressure. If used as an alternate source for static air, instrument indications would be grossly inaccurate. In this case, multiple static vent pickup points are employed. All are located on the outside of the aircraft and plumbed so the pilot can select which source directs air into the instruments. On electronic flight displays, the choice is made for which source is used by the computer or by the flight crew.

On unpressurized aircraft, an alternate source of static air is cabin air.

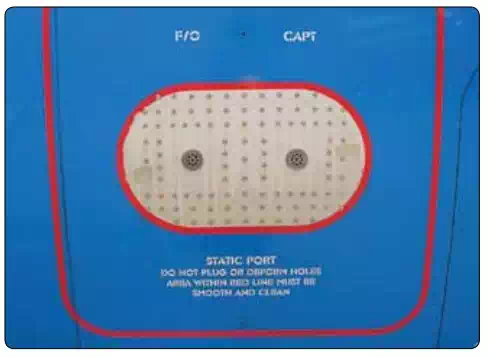

Another type of pitot-static system provides for the location of the pitot and static sources at separate positions on the aircraft. The pitot tube in this arrangement is used only to gather ram air pressure. Separate static vents are used to collect static air pressure information. Usually, these are located flush on the side of the fuselage. There may be two or more vents. A primary and alternate source vent is typical, as well as separate dedicated vents for the pilot and first officer’s instruments. Also, two primary vents may be located on opposite sides of the fuselage and connected with Y tubing for input to the instruments. This is done to compensate for any variations in static air pressure on the vents due to the aircraft’s attitude. Regardless of the number and location of separate static vents, they may be heated as well as the separate ram air pitot tube to prevent icing.

Heated primary and alternate static vents located on the sides of the fuselage.

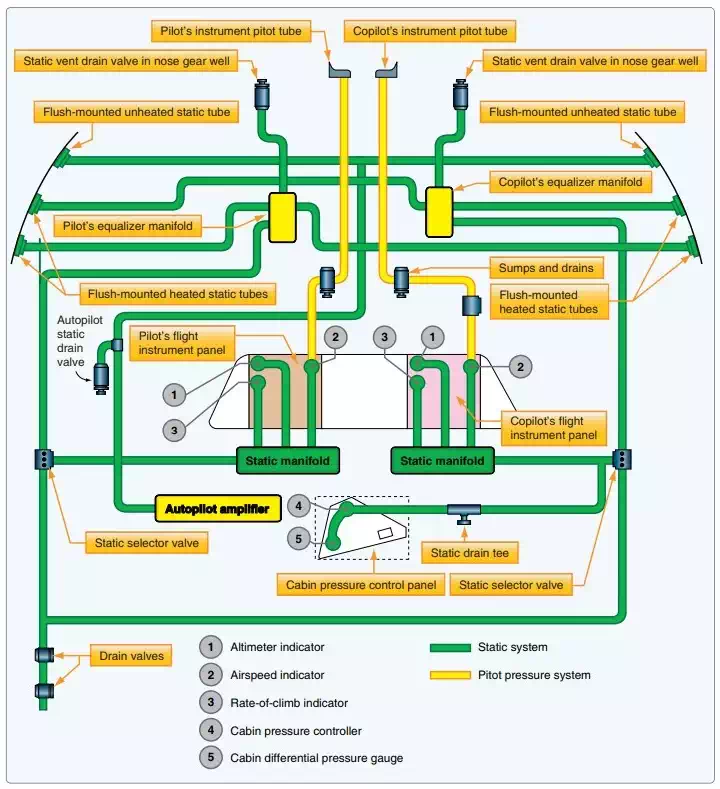

The pitot-static systems of complex, multiengine, and pressurized aircraft can be elaborate. Additional instruments, gauges, the autopilot system, and computers may need pitot and static air information. Figure below shows a pitot-static system for a pressurized multiengine aircraft with dual analog instrument panels in the cockpit. The additional set of flight instruments for the copilot alters and complicates the pitot-static system plumbing. Additionally, the autopilot system requires static pressure information, as does the cabin pressurization unit. Separate heated sources for static air pressure are taken from both sides of the airframe to feed independent static air pressure manifolds; one each for the pilot’s flight instruments and the copilot’s flight instruments. This is designed to ensure that there is always one set of flight instruments operable in case of a malfunction.