Boundary Layer Separation and Pressure Drag

At the start of the 19th century, after studying the highly cambered

thin wings of many different birds, Sir George Cayley designed and built the

first modern aerofoil, later used on a hand-launched glider. This biomimetic,

highly cambered and thin-walled design remained the predominant aerofoil shape

for almost 100 years, mainly due to the fact that the actual mechanisms of lift

and drag were not understood scientifically but were explored in an empirical

fashion. One of the major problems with these early aerofoil designs was that

they experienced a phenomenon now known as boundary layer separation at

very low angles of attack. This significantly limited the amount of lift that

could be created by the wings and meant that bigger and bigger wings were needed

to allow for any progress in terms of aircraft size. Lacking the analytical

tools to study this problem, aerodynamicists continued to advocate thin

aerofoil sections, as there was plenty of evidence in nature to suggest their

efficacy. The problem was considered to be more one of degree, i.e.

incrementally iterating the aerofoil shapes found in nature, rather than of

type, that is designing an entirely new shape of aerofoil in accord with

fundamental physics.

During the pre-WWI era, the misguided notions of designers was

compounded by the ever-increasing use of wind-tunnel tests. The wind tunnels

used at the time were relatively small and ran at very low flow speeds. This

meant that the performance of the aerofoils was being tested under the

conditions of laminar flow (smooth flow in layers, no mixing perpendicular to

flow direction) rather than the turbulent flow (mixing of flow via small

vortices) present over the wing surfaces. Under laminar flow conditions,

increasing the thickness of an aerofoil increases the amount of skin-friction

drag (as shown in last month’s post), and hence thinner aerofoils were

considered to be superior.

The modern plane – born in 1915

The situation in Germany changed dramatically during WWI. In 1915 Hugo

Junkers pioneered the first practical all-metal aircraft with a cantilevered

wing – essentially the same semi-monocoque wing

box design used today. The most popular design up to then was the

biplane configuration held together by wires and struts, which introduced

considerable amounts of parasitic drag and thereby limited the maximum speed of

aircraft. Eliminating these supporting struts and wires meant that the flight

loads needed to be carried by other means. Junkers cantilevered a beam from

either side of the fuselage, the main spar, at about 25% of the chord of the

wing to resist the up and down bending loads produced by lift. Then he fitted a

smaller second spar, known as the trailing edge spar, at 75% of the chord to

assist the main spar in resisting fore and aft bending induced by the drag on

the wing. The two spars were connected by the external wing skin to produce a

closed box-section known as the wing box. Finally, a curved piece of metal was

fitted to the front of the wing to form the “D”-shaped leading edge, and two

pieces of metal were run out to form the trailing edge. This series of three

closed sections provided the wing with sufficient torsional rigidity to sustain

the twisting loads that arise because the aerodynamic centre (the point where

the lift force can be considered to act) is offset from the shear centre (the

point where a vertical load will only cause bending and no twisting). Junker’s

ideas were all combined in the world’s first practical all-metal aircraft, the

Junker J 1, which although much heavier than other aircraft at the time,

developed into the predominant form of construction for the larger and faster

aircraft of the coming generation.

Junkers J 1 at Döberitz in

1915

Structures + Aerodynamics = Superior

Aircraft

Junkers construction naturally resulted in a much thicker wing due to

the room required for internal bracing, and this design provided the impetus

for novel aerodynamics research. Junker’s ideas were supported by Ludwig Prandtl who carried out his famous aerodynamics work

at the University of Göttingen. As discussed

in last month’s post, Prandtl had

previously introduced the notion of the boundary layer; namely the existence of

a U-shaped velocity profile with a no-flow condition at the surface and an

increasing velocity field towards the main stream some distance away from the

surface. Prandtl argued that the presence

of a boundary layer supported the simplifying assumption that fluid flow can be

split into two non-interacting portions; a thin layer close to the surface

governed by viscosity (the stickiness of the fluid) and an inviscid mainstream.

This allowed Prandtl and his colleagues to

make much more accurate predictions of the lift and drag performance of

specific wing-shapes and greatly helped in the design of German WWI aircraft.

In 1917 Prandtl showed that Junker’s thick

and less-cambered aerofoil section produced much more favourable lift

characteristics than the classic thinner sections used by Germany’s enemies.

Second, the thick aerofoil could be flown at a much higher angle of attack

without stalling and hence improved the manoeuvrability of a plane during dog

fighting.

Skin Friction versus Pressure Drag

The flow in a boundary layer can be either laminar or turbulent. Laminar

flow is orderly and stratified without interchange of fluid particles between

individual layers, whereas in turbulent flow there is significant exchange of

fluid perpendicular to the flow direction. The type of flow greatly influences

the physics of the boundary layer. For example, due to the greater extent of

mass interchange, a turbulent boundary layer is thicker than a laminar one and

also features a steeper velocity gradient close to the surface, i.e. the flow

speed increases more quickly as we move away from the wall.

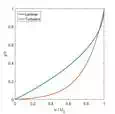

Velocity

profile of laminar versus turbulent boundary layer. Note how the turbulent flow

increases velocity more rapidly away from the wall.

Just like your hand experiences friction when sliding over a surface, so

do layers of fluid in the boundary layer, i.e. the slower regions of the flow

are holding back the faster regions. This means that the velocity gradient

throughout the boundary layer gives rise to internal shear stresses that are

akin to friction acting on a surface. This type of friction is aptly

called skin-friction drag and is predominant in streamlined

flows where the majority of the body’s surface is aligned with the flow. As the

velocity gradient at the surface is greater for turbulent than laminar flow, a

streamlined body experiences more drag when the boundary layer flow over its

surfaces is turbulent. A typical example of a streamlined body is an aircraft

wing at cruise, and hence it is no surprise that maintaining laminar flow over

aircraft wings is an ongoing research topic.

Over flat surfaces we can suitably ignore any changes in pressure in the

flow direction. Under these conditions, the boundary layer remains stable but

grows in thickness in the flow direction. This is, of course, an idealised

scenario and in real-world applications, such as curved wings, the flow is most

likely experiencing an adverse pressure gradient, i.e. the pressure increases

in the flow direction. Under these conditions the boundary layer can become

unstable and separate from the surface. The boundary layer separation induces a

second type of drag, known as pressure drag. This type of drag is

predominant for non-streamlined bodies, e.g. a golfball flying

through the air or an aircraft wing at a high angle of attack.

So why does the flow separate in the first

place?

To answer this question consider fluid flow over a cylinder. Right at

the front of the cylinder fluid particles must come to rest. This point is

aptly called the stagnation point and is the point of maximum pressure (to

conserve energy the pressure needs to fall as fluid velocity increases, and

vice versa). Further downstream, the curvature of the cylinder causes the flow

lines to curve, and in order to equilibrate the centripetal forces, the

flow accelerates and the fluid pressure drops. Hence, an area of accelerating

flow and falling pressure occurs between the stagnation point and the poles of

the cylinder. Once the flow passes the poles, the curvature of the cylinder is

less effective at directing the flow in curved streamlines due to all the open

space downstream of the cylinder. Hence, the curvature in the flow reduces and

the flow slows down, turning the previously favourable pressure gradient into

an adverse pressure gradient of rising pressure.

Boundary layer separation over a cylinder (axis out out the page).

To understand boundary layer separation we need to understand how these

favourable and adverse pressure gradients influence the shape of the boundary

layer. From our discussion on boundary layers, we know that the fluid travels

slower the closer we are to the surface due to the retarding action of the

no-slip condition at the wall. In a favourable pressure gradient, the falling

pressure along the streamlines helps to urge the fluid along, thereby

overcoming some of the decelerating effects of the fluid’s viscosity. As a

result, the fluid is not decelerated as much close to the wall leading to a

fuller U-shaped velocity profile, and the boundary layer grows more slowly.

By analogy, the opposite occurs for an adverse pressure gradient, i.e.

the mainstream pressure increases in the flow direction retarding the flow in

the boundary layer. So in the case of an adverse pressure gradient the pressure

forces reinforce the retarding viscous friction forces close to the surface. As

a result, the difference between the flow velocity close to the wall and the

mainstream is more pronounced and the boundary layer grows more quickly. If the

adverse pressure gradient acts over a sufficiently extended distance, the

deceleration in the flow will be sufficient to reverse the direction of

flow in the boundary layer. Hence the boundary layer develops a point of

inflection, known as the point of boundary layer separation, beyond

which a circular flow pattern is established.

For aircraft wings, boundary layer separation can lead to very

significant consequences ranging from an increase in pressure drag to a

dramatic loss of lift, known as aerodynamic stall. The shape of an aircraft

wing is essentially an elongated and perhaps asymmetric version of the cylinder

shown above. Hence the airflow over the top convex surface of a wing follows

the same basic principles outlined above:

● There is a point of stagnation at the leading edge.

● A region of accelerating mainstream flow (favourable pressure gradient)

up to the point of maximum thickness.

● A region of decelerating mainstream flow (adverse pressure gradient)

beyond the point of maximum thickness.

These three points are summarised in the schematic diagram below.

Boundary layer separation over the top surface of a wing.

Boundary layer separation is an important issue for aircraft wings as it

induces a large wake that completely changes the flow downstream of the point

of separation. Skin-friction drag arises due to inherent viscosity of the

fluid, i.e. the fluid sticks to the surface of the wing and the associated

frictional shear stress exerts a drag force. When a boundary layer separates, a

drag force is induced as a result of differences in pressure upstream and

downstream of the wing. The overall dimensions of the wake, and therefore the

magnitude of pressure drag, depends on the point of separation along the wing.

The velocity profiles of turbulent and laminar boundary layers (see image

above) show that the velocity of the fluid increases much slower away from the

wall for a laminar boundary layer. As a result, the flow in a laminar boundary

layer will reverse direction much earlier in the presence of an adverse

pressure gradient than the flow in a turbulent boundary layer.

To summarise, we now know that the inherent viscosity of a fluid leads

to the presence of a boundary layer that has two possible sources of drag.

Skin-friction drag due to the frictional shear stress between the fluid and the

surface, and pressure drag due to flow separation and the existence of a

downstream wake. As the total drag is the sum of these two effects, the

aerodynamicist is faced with a non-trivial compromise:

● skin-friction drag is reduced by laminar flow due to a lower shear stress at the

wall, but this increases pressure drag when boundary layer separation occurs.

● pressure drag

is reduced by turbulent flow by delaying boundary layer separation, but this

increases the skin-friction drag due to higher shear stresses at the wall.

As a result, neither laminar nor turbulent flow can be said to be

preferable in general and judgement has to be made regarding the specific

application. For a blunt body, such as a cylinder, pressure drag dominates and

therefore a turbulent boundary layer is preferable. For more streamlined

bodies, such as an aircraft wing at cruise, the overall drag is dominated by

skin-friction drag and hence a laminar boundary layer is preferable. Dolphins,

for example, have very streamlined bodies to maintain laminar flow. Early

golfers, on the other hand, realised that worn rubber golf balls flew further

than pristine ones, and this led to the innovation of dimples on golf balls.

Fluid flow over golf balls is predominantly laminar due to the relatively low

flight speeds. Dimples are therefore nothing more than small imperfections that

transform the predominantly laminar flow into a turbulent one that delays the

onset of boundary layer separation and therefore reduces pressure drag.

Aerodynamic Stall

The second, and more dramatic effect, of boundary layer separation in

aircraft wings is aerodynamic stall. At relatively low angles of attack, for

example during cruise, the adverse pressure gradient acting on the top surface

of the wing is benign and the boundary layer remains attached over the entire

surface. As the angle of attack is increased, however, so does the pressure

gradient. At some point the boundary layer will start to separate near the

trailing edge of the wing, and this separation point will move further upstream

as the angle of attack is increased. If an aerofoil is positioned at a

sufficiently large angle of attack, separation will occur very close to the

point of maximum thickness of the aerofoil and a large wake will develop behind

the point of separation. This wake redistributes the flow over the rest of the

aerofoil and thereby significantly impairs the lift generated by the wing. As a

result, the lift produced is seriously reduced in a condition known as aerodynamic

stall. Due to the high pressure drag induced by the wake, the aircraft can

further lose airspeed, pushing the separation point further upstream and creating

a deleterious feedback loop where the aircraft literally starts to fall out of

the sky in an uncontrolled spiral. To prevent total loss of control, the pilot

needs to reattach the boundary as quickly as possible which is achieved by

reducing the angle of attack and pointing the nose of the aircraft down to gain

speed.

The lift produced by a wing is given by

![]()

where ![]() is

the density of the surrounding air,

is

the density of the surrounding air, ![]() is

the flight velocity,

is

the flight velocity, ![]() is

the wing area and

is

the wing area and ![]() is

the lift coefficient of the aerofoil shape. The lift coefficient of a specific

aerofoil shape increases linearly with the angle of attack up to a

maximum point

is

the lift coefficient of the aerofoil shape. The lift coefficient of a specific

aerofoil shape increases linearly with the angle of attack up to a

maximum point ![]() . The maximum lift coefficient

of a typical aerofoil is around 1.4 at an angle of attack of around

. The maximum lift coefficient

of a typical aerofoil is around 1.4 at an angle of attack of around ![]() , which

is bounded by the critical angle of attack where the stall condition occurs.

, which

is bounded by the critical angle of attack where the stall condition occurs.

During cruise the angle of attack is relatively small (![]() ) as

sufficient lift is guaranteed by the high flight velocity

) as

sufficient lift is guaranteed by the high flight velocity ![]() . Furthermore, we actually want to maintain a small angle of

attack as this minimises the pressure drag induced by boundary layer

separation. At takeoff and landing,

however, the flight velocity is much smaller which means that the lift

coefficient has to be increased by setting the wings at a more aggressive angle

of attack (

. Furthermore, we actually want to maintain a small angle of

attack as this minimises the pressure drag induced by boundary layer

separation. At takeoff and landing,

however, the flight velocity is much smaller which means that the lift

coefficient has to be increased by setting the wings at a more aggressive angle

of attack (![]() ). The

issue is that even with a near maximum lift coefficient of 1.4, large jumbo

jets have a hard time achieving the necessary lift force at safe speeds for

landing. While it would also be possible to increase the wing area, such a

solution would have detrimental effect on the aircraft weight and therefore

fuel efficiency.

). The

issue is that even with a near maximum lift coefficient of 1.4, large jumbo

jets have a hard time achieving the necessary lift force at safe speeds for

landing. While it would also be possible to increase the wing area, such a

solution would have detrimental effect on the aircraft weight and therefore

fuel efficiency.

High-lift Devices

A much more elegant solution are leading-edge slats and trailing-edge

flaps. A slat is a thin, curved aerofoil that is fitted to the front of the

wing and is intended to induce a secondary airflow through the gap between the

slat and the leading edge. The air accelerates through this gap and thereby

injects high momentum fluid into the boundary on the upper surface, delaying

the onset of flow reversal in the boundary layer. Similarly, one or two curved

aerofoils may be placed at the rear of wing in order to invigorate the flow

near the trailing edge. In this case the high momentum fluid reinvigorates the

flow which has been slowed down by the adverse pressure gradient. The maximum

lift coefficient can typically be doubled by these devices and therefore allows

big jumbo jets to land and takeoff at

relatively low runway speeds.

Leading edge slats and trailing edge flaps on an aircraft

wing

The next time you are sitting close to the wings observe how these

devices are retracted after take-off and activated before landing. In fact,

birds have a similar devices on their wings. The wings of bats are comprised of

thin and flexible membranes reinforced by small bones which roughen the

membrane surface and help to transition the flow from laminar to turbulent and

prevent boundary layer separation. As is so often the case in engineering design,

a lot of inspiration can be taken from nature!

Smart

Materials Application: Variable Geometry Chevron for Noise Reduction

For many years engineers have been trying to harness mechanical work

from thermal energy by taking advantage of the crystallographic phase change

of shape memory alloys (SMA’s). SMA’s can exhibit strains of

up to 8% actuated by a transformation of the internal crystal structure

from martensite to austenite as the metal

is heated. This solid state phase change causes a shearing of the internal

structure that deforms the material. By introducing additional internal

stresses the alloy can be “trained” to transition between two states by

applying temperature changes. One of the most well-known projects of the past

is the Smart Aircraft and Marine Propulsion System demonstration

(SAMPSON), intending to demonstrate the potential of SMA’s in tailoring the

geometry of jet-propulsion systems through a series of experiments.

Boeing variable geometry chevron, flight testing (1)

One experiment investigated the utilisation of bending actuation of

SMA’s to optimise the compromise between noise-mitigation at take-off and

landing (noise levels are strictly regulated by civil agencies), and maximum

thrust at cruise altitude. To achieve this Boeing formed the trailing edge of

the exhaust nozzles on commercial turbo-fat jet engines in a triangular

“chevron” shape (Figure 1) designed to be reconfigurable by actuation of

embedded SMA beam components. The “Variable Geometry Chevrons” (Figure

2) feature NiTi (60% Ni and 40% Ti by weight) SMA beam elements encased in the

composite chevrons in a complex 3-D configuration to induce the necessary

bending moments to force the chevrons inwards into the bypass flow at low

altitudes and low speeds where the engine temperature is high. The intruding

chevrons cause a disturbance in the bypass flow, inducing a broader diffusion

and mixing of the hot exhaust gases with the cooler bypass flow. Thereby the

shear stress between the two different-velocity flows is decreased leading to a

reduction in the noise level.

FEA analysis of Boeing Variable Geometry Chevron with SMA

strips shown (1)

At higher altitudes and high speeds where the engine temperature is low,

the chevrons relax and straighten-out. This guarantees a smooth exit flow that

decreases the pressure difference between the inlet and exit of the engine and

thus increases the engine thrust. In the original work published by Mabe et al. (2005) the system is designed for both

autonomous operation as well as controlled actuation using heaters installed in

the engine casing with a closed loop controller to maintain optimum in-flight

tip immersions. A parametric study showed that during cruise marginal immersion

helped to reduce shock cell noise with negligible thrust penalty.

NASA developed an active bending chevron system by embedding tensile

pre-stressed NiTinol SMA strips on one side of the neutral axis of the composite

laminate. Actively controlled thermal excitation thus causes the SMA actuators

to attempt recovery of the pre-strain constrained by the bond to the host

material. The resulting asymmetry in thermal stress causes a moment

that deflects the structure. The aerodynamic load due to engine flow

and the strain energy stored in the deformed host composite are used to restore

the structure to the un-actuated configuration.

The simple design appeals by its lightweight construction with low part

count and opportunity to be fully integrated into an autonomous morphing

system. The “Variable Geometry Chevron” demonstrates the excellent

potential of SMA’s to be integrated in composite laminates to provide internal

actuation for smart structures.