On Boundary

Layers: Laminar, Turbulent and Skin Friction

In the early 20th century, a group of German scientists led by

Ludwig Prandtl at the University of Göttingen began studying the fundamental nature of

fluid flow and subsequently laid the foundations for modern aerodynamics. In

1904, just a year after the first flight by the Wright brothers, Prandtl published the first paper on a new concept,

now known as the boundary layer. In the following years, Prandtl worked on supersonic flow and spent most of

his time developing the foundations for wing theory, ultimately leading to the

famous red triplane flown by Baron von Richthofen,

the Red Baron, during WWI.

Prandtl’s key insight in the

development of the boundary layer was that as a first-order approximation it is

valid to separate any flow over a surface into two regions: a thin boundary

layer near the surface where the effects of viscosity cannot be ignored, and a

region outside the boundary layer where viscosity is negligible. The nature of

the boundary layer that forms close to the surface of a body significantly

influences how the fluid and body interact. Hence, an understanding of boundary

layers is essential in predicting how much drag an aircraft experiences, and is

therefore a mandatory requirement in any first course on aerodynamics.

Boundary layers develop due to the inherent stickiness or viscosity of

the fluid. As a fluid flows over a surface, the fluid sticks to the solid

boundary which is the so-called “no-slip condition”. As sudden jumps in flow

velocity are not possible for flow continuity requirements, there must exist a

small region within the fluid, close to the body over which the fluid is

flowing, where the flow velocity increases from zero to the mainstream

velocity. This region is the so-called boundary layer.

The U-shaped profile of the boundary layer can be visualised by

suspending a straight line of dye in water and allowing fluid flow to distort

the line of dye (see below). The distance of a distorted dye particle to its

original position is proportional to the flow velocity. The fluid is stationary

at the wall, increases in velocity moving away from the wall, and then

converges to the constant mainstream value ![]() at

a distance

at

a distance ![]() equal

to the thickness of the boundary layer.

equal

to the thickness of the boundary layer.

To further investigate the nature of the flow within the boundary layer,

let’s split the boundary layer into small regions parallel to the surface and

assume a constant fluid velocity within each of these regions (essentially the

arrows in the figure above). We have established that the boundary layer is

driven by viscosity. Therefore, adjacent regions within the boundary layer that

move at slightly different velocities must exert a frictional force on each

other. This is analogous to you running your hand over a table-top surface and

feeling a frictional force on the palm of your hand. The shear stresses ![]() inside the fluid are a function of

the viscosity or stickiness of the fluid

inside the fluid are a function of

the viscosity or stickiness of the fluid ![]() , and also the velocity gradient

, and also the velocity gradient ![]() :

:

![]()

where ![]() is

the coordinate measuring the distance from the solid boundary, also called the

“wall”.

is

the coordinate measuring the distance from the solid boundary, also called the

“wall”.

Prandtl first noted that shearing

forces are negligible in mainstream flow due to the low viscosity of most

fluids and the near uniformity of flow velocities in the mainstream. In the

boundary layer, however, appreciable shear stresses driven by steep velocity

gradients will arise.

So the pertinent question is: Do these two regions influence

each other or can they be analysed separately?

Prandtl argued that for flow

around streamlined bodies, the thickness of the boundary layer is an order of

magnitude smaller than the thickness of the mainstream, and therefore the

pressure and velocity fields around a streamlined body may analysed

disregarding the presence of the boundary layer.

Eliminating the effect of viscosity in the free flow is an enormously

helpful simplification in analysing the flow. Prandtl’s assumption

allows us to model the mainstream flow using Bernoulli’s equation or the

equations of compressible flow that we have discussed before, and this was a

major impetus in the rapid development of aerodynamics in the 20th century.

Today, the engineer has a suite of advanced computational tools at hand to

model the viscid nature of the entire flow. However, the idea of

partitioning the flow into an inviscid mainstream and viscid boundary layer is

still essential for fundamental insights into basic aerodynamics.

Laminar and turbulent boundary layers

One simple example that nicely demonstrates the physics of boundary

layers is the problem of flow over a flat plate.

Development of

boundary layer over a flat plate including the transition from a laminar to

turbulent boundary layer.

The fluid is streaming in from the left with a free stream velocity ![]() and due to the no-slip condition

slows down close to the surface of the plate. Hence, a boundary layer starts to

form at the leading edge. As the fluid proceeds further downstream, large

shearing stresses and velocity gradients develop within the boundary layer.

Proceeding further downstream, more and more fluid is slowed down and therefore

the thickness,

and due to the no-slip condition

slows down close to the surface of the plate. Hence, a boundary layer starts to

form at the leading edge. As the fluid proceeds further downstream, large

shearing stresses and velocity gradients develop within the boundary layer.

Proceeding further downstream, more and more fluid is slowed down and therefore

the thickness, ![]() , of the boundary layer grows.

As there is no sharp line splitting the boundary layer from the free-stream,

the assumption is typically made that the boundary layer extends to the point

where the fluid velocity reaches 99% of the free stream. At all times, and

at at any distance

, of the boundary layer grows.

As there is no sharp line splitting the boundary layer from the free-stream,

the assumption is typically made that the boundary layer extends to the point

where the fluid velocity reaches 99% of the free stream. At all times, and

at at any distance ![]() from the leading edge, the thickness of the boundary

layer

from the leading edge, the thickness of the boundary

layer ![]() is

small compared to

is

small compared to ![]() .

.

Close to the leading edge the flow is entirely laminar,

meaning the fluid can be imagined to travel in strata, or lamina, that do not

mix. In essence, layers of fluid slide over each other without any interchange

of fluid particles between adjacent layers. The flow speed within each

imaginary lamina is constant and increases with the distance from the surface.

The shear stress within the fluid is therefore entirely a function of the

viscosity and the velocity gradients.

Further downstream, the laminar flow becomes unstable and fluid

particles start to move perpendicular to the surface as well as parallel to it.

Therefore, the previously stratified flow starts to mix up and fluid particles

are exchanged between adjacent layers. Due to this seemingly random motion this

type of flow is known as turbulent. In a turbulent boundary layer,

the thickness ![]() increases

at a faster rate because of the greater extent of mixing within the main flow.

The transverse mixing of the fluid and exchange of momentum between individual

layers induces extra shearing forces known as the Reynolds stresses. However,

the random irregularities and mixing in turbulent flow cannot occur in the

close vicinity of the surface, and therefore a viscous sublayer forms beneath

the turbulent boundary layer in which the flow is laminar.

increases

at a faster rate because of the greater extent of mixing within the main flow.

The transverse mixing of the fluid and exchange of momentum between individual

layers induces extra shearing forces known as the Reynolds stresses. However,

the random irregularities and mixing in turbulent flow cannot occur in the

close vicinity of the surface, and therefore a viscous sublayer forms beneath

the turbulent boundary layer in which the flow is laminar.

An excellent example contrasting the differences in turbulent and

laminar flow is the smoke rising from a cigarette.

Laminar and turbulent flow in smoke

As smoke rises it transforms from a region of smooth laminar flow to a

region of unsteady turbulent flow. The nature of the flow, laminar or

turbulent, is captured very efficiently in a single parameter known as the

Reynolds number

![]()

where ![]() is the density of the fluid,

is the density of the fluid, ![]() the local flow velocity,

the local flow velocity, ![]() a characteristic length describing the geometry,

and

a characteristic length describing the geometry,

and ![]() is

the viscosity of the fluid.

is

the viscosity of the fluid.

There exists a critical Reynolds number in the region ![]() for which the flow

transitions from laminar to turbulent. For the plate example above, the

characteristic length is the distance from the leading edge. Therefore

for which the flow

transitions from laminar to turbulent. For the plate example above, the

characteristic length is the distance from the leading edge. Therefore ![]() increases as we proceed downstream, increasing the

Reynolds number until at some point the flow transitions from laminar to

turbulent. The faster the free stream velocity

increases as we proceed downstream, increasing the

Reynolds number until at some point the flow transitions from laminar to

turbulent. The faster the free stream velocity ![]() , the shorter the distance from the leading edge where this

transition occurs.

, the shorter the distance from the leading edge where this

transition occurs.

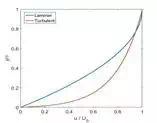

Velocity profiles

Due to the different degrees of fluid mixing in laminar and turbulent

flows, the shape of the two boundary layers is different. The increase in fluid

velocity moving away from the surface (y-direction) must be continuous in order

to guarantee a unique value of the velocity gradient ![]() . For a discontinuous change in

velocity, the velocity gradient

. For a discontinuous change in

velocity, the velocity gradient ![]() , and therefore the shearing

forces

, and therefore the shearing

forces ![]() would

be infinite, which is obviously not feasible in reality. Hence, the velocity

increases smoothly from zero at the wall in some form of parabolic

distribution. The further we move away from the wall, the smaller the velocity

gradient and the retarding action of the shearing stresses decreases.

would

be infinite, which is obviously not feasible in reality. Hence, the velocity

increases smoothly from zero at the wall in some form of parabolic

distribution. The further we move away from the wall, the smaller the velocity

gradient and the retarding action of the shearing stresses decreases.

In the case of laminar flow, the shape of the boundary layer is indeed

quite smooth and does not change much over time. For a turbulent boundary layer

however, only the average shape of the boundary layer approximates the

parabolic profile discussed above. The figure below compares a typical laminar

layer with an averaged turbulent layer.

Velocity profile of laminar versus turbulent boundary layer

In the laminar layer, the kinetic energy of the free flowing fluid is

transmitted to the slower moving fluid near the surface purely means by of

viscosity, i.e. frictional shear stresses. Hence, an imaginary fluid layer

close to the free stream pulls along an adjacent layer close to the wall, and

so on. As a result, significant portions of fluid in the laminar boundary layer

travel at a reduced velocity. In a turbulent boundary layer, the kinetic energy

of the free stream is also transmitted via Reynolds stresses, i.e. momentum

exchanges due to the intermingling of fluid particles. This leads to a more

rapid rise of the velocity away from the wall and a more uniform fluid velocity

throughout the entire boundary layer. Due to the presence of the viscous

sublayer in the close vicinity of the wall, the wall shear stress in a

turbulent boundary layer is governed by the usual equation ![]() . This

means that because of the greater velocity gradient at the wall the frictional

shear stress in a turbulent boundary is greater than in a purely laminar

boundary layer.

. This

means that because of the greater velocity gradient at the wall the frictional

shear stress in a turbulent boundary is greater than in a purely laminar

boundary layer.

Skin Friction drag

Fluids can only exert two types of forces: normal forces due to pressure

and tangential forces due to shear stress. Pressure drag is the phenomenon that

occurs when a body is oriented perpendicular to the direction of fluid flow.

Skin friction drag is the frictional shear force exerted on a body aligned

parallel to the flow, and therefore a direct result of the viscous boundary

layer.

Due to the greater shear stress at the wall, the skin friction drag is

greater for turbulent boundary layers than for laminar ones. Skin friction drag

is predominant in streamlined aerodynamic profiles, e.g. fish, airplane wings,

or any other shape where most of the surface area is aligned with the flow

direction. For these profiles, maintaining a laminar boundary layer is preferable.

For example, the crescent lunar shaped tail of many sea mammals or fish has

evolved to maintain a relatively constant laminar boundary layer when

oscillating the tail from side to side.

One of Prandtl’s PhD students, Paul

Blasius, developed an analytical expression for the shape of a laminar boundary

layer over a flat plate without a pressure gradient. Blasius’ expression has

been verified by experiments many times over and is considered a standard in

fluid dynamics. The two important quantities that are of interest to the

designer are the boundary layer thickness ![]() and the shear stress at

the wall

and the shear stress at

the wall ![]() at

a distance

at

a distance ![]() from

the leading edge. The boundary layer thickness is given by

from

the leading edge. The boundary layer thickness is given by

![]()

with ![]() the Reynolds number at a

distance

the Reynolds number at a

distance ![]() from

the leading edge. Due to the presence of

from

the leading edge. Due to the presence of ![]() in

the numerator and

in

the numerator and ![]() in

the denominator, the boundary layer thickness scales proportional to

in

the denominator, the boundary layer thickness scales proportional to ![]() , and

hence increases rapidly in the beginning before settling down.

, and

hence increases rapidly in the beginning before settling down.

Next, we can use a similar expression to determine the shear stress at

the wall. To do this we first define another non dimensional number known as

the drag coefficient

![]()

which is the value of the shear stress at

the wall normalised by the dynamic pressure of the free-flow. According to

Blasius, the skin-friction drag coefficient is simply governed by the Reynolds

number

![]()

This simple example reiterates the power of dimensionless numbers we

mentioned before when discussing wind tunnel testing. Even though the

shear stress at the wall is a dimensional quantity, we have been able to

express it merely as a function of two non-dimensional quantities ![]() and

and ![]() . By combining the two equations above, the

shear stress can be written as

. By combining the two equations above, the

shear stress can be written as

![]()

and therefore scales proportional

to ![]() ,

tending to zero as the distance from the leading edge increases. The value

of

,

tending to zero as the distance from the leading edge increases. The value

of ![]() is

the frictional shear stress at a specific point

is

the frictional shear stress at a specific point ![]() from the leading edge. To find the total amount of

drag

from the leading edge. To find the total amount of

drag ![]() exerted

on the plate we need to sum up (integrate) all contributions of

exerted

on the plate we need to sum up (integrate) all contributions of ![]() over the length of the

plate

over the length of the

plate

![]()

where ![]() is now the Reynolds number of the

free stream calculated using the total length of the plate

is now the Reynolds number of the

free stream calculated using the total length of the plate ![]() . Similar to the skin friction coefficient

. Similar to the skin friction coefficient ![]() we can define a total skin friction

drag coefficient

we can define a total skin friction

drag coefficient ![]()

![]()

Hence, ![]() can

be used to calculate the local amount of shear stress at a point

can

be used to calculate the local amount of shear stress at a point ![]() from the leading edge, whereas

from the leading edge, whereas ![]() is used to find the total

amount of skin friction drag acting on the surface.

is used to find the total

amount of skin friction drag acting on the surface.

Unfortunately, do to the chaotic nature

of turbulent flow, the boundary layer thickness and skin drag coefficient for a

turbulent boundary layer cannot be determined as easily in a theoretical

manner. Therefore we have to rely on experimental results to define empirical

approximations of these quantities. The scientific consensus of the these relations are as follows:

![]()

![]()

Therefore the thickness of a turbulent boundary layer grows proportional

to ![]() (faster

than the

(faster

than the ![]() relation

for laminar flow) and the total skin friction drag coefficient varies as

relation

for laminar flow) and the total skin friction drag coefficient varies as ![]() (also faster than

the

(also faster than

the ![]() relation

of laminar flow). Hence, the total skin drag coefficient confirms the

qualitative observations we made before that the frictional shear stresses in a

turbulent boundary layer are greater than those in a laminar one.

relation

of laminar flow). Hence, the total skin drag coefficient confirms the

qualitative observations we made before that the frictional shear stresses in a

turbulent boundary layer are greater than those in a laminar one.

Skin friction drag and wing design

The unfortunate fact for aircraft designers is that turbulent flow is

much more common in nature than laminar flow. The tendency for flow to be

random rather than layered can be interpreted in a similar way to the second

law of thermodynamics. The fact that entropy in a closed system only increases

is to say that, if left to its own devices, the state in the system will tend

from order to disorder. And so it is with fluid flow.

However, the shape of a wing can be designed in such a manner as to

encourage the formation of laminar flow. The P-51 Mustang WWII fighter was the

first production aircraft designed to operate with laminar flow over its wings.

The problem back then, and to this day, is that laminar flow is incredibly

unstable. Protruding rivet heads or splattered insects on the wing surface can

easily “trip” a laminar boundary layer into turbulence, and preempt any clever design the engineer concocted. As a

result, most of the laminar flow wings that have been designed based on

idealised conditions and smooth wing surfaces in a wind tunnel have not led to

the sweeping improvements originally imagined.

For many years NASA conducted a series of experiments to design a

natural laminar flow (NLF) aircraft. Some of their research suggested the

wrapping of a glove around the leading edge of a Boeing 757 just outboard of

the engine. The modified shape of this wing promotes laminar flow at the high

altitudes and almost sonic flight conditions of a typical jet airliner. To

prevent the build up of insect splatter at

take-off a sheath of paper was wrapped around the glove which was then torn

away at altitude. Even though the range of such an aircraft could be increased

by almost 15% this, rather elaborate scheme, never made it into production.

In the mid 1990s NASA fitted active

test panels to the wings of two F-16’s in order to test the possibility of

achieving laminar flow on swept delta-wings flying at supersonic speed; in

NASA’s view a likely wing configuration for future supersonic cruise aircraft.

The active test panels essentially consisted of titanium covers perforated with

millions of microscopic holes, which were attached to the leading edge and the

top surface of the wing. The role of these panels was to suck most of the

boundary layer off the top surface through perforations using an internal

pumping system. By removing air from the boundary layer its thickness decreased

and thereby promoted the stability of the laminar boundary layer over the wing.

This Supersonic Laminar Flow (SLFC) project successfully maintained laminar

flow over a large portion of the wing during supersonic flight of up to Mach

1.6.

F-16 XL with suction panels to promote laminar flow

While these elaborate schemes have not quite found their way into mass

production (probably due to their cost, maintenance problems and risk), laminar

flow wings are a very viable future technology in terms of reducing greenhouse

gases as stipulated by environmental legislation. An important driver in

reducing greenhouse gases is maximising the lift-to-drag ratio of the wings,

and therefore I would expect research to continue in this field for some time

to come.