Fancy a Sandwich?

In this post I want to use the sandwich panel as an example to explain

some basic concepts about bending of structures. The explanations in this post

are kept very basic and are similar to a first semester course in structural

mechanics. Sandwich panels are an important composite structure in aerospace

applications as well as in high performance automobiles, boats and wind

turbines. Typically a sandwich panel is comprised of a low stiffness, low

density inner core enclosed by two stiff outer skins, as shown in Figure 1,

where the whole assembly is held together by some sort of structural adhesive

(Figure 2). The outer skins are typically made from stiff carbon fibre or

aerospace grade aluminium.

Fig. 1. A honeycomb carbon fibre sandwich panel (1)

Fig. 2. Sandwich panel components and construction

The inner core is typically a Nomex or

metal honeycomb, or an open or closed cell foam. Nomex is

an aramid polymer similar to Nylon that is flame-resistant and can be manufactured

in paper sheet form. Nomex is a great

choice for the interior of aircraft cabins such as the floor panels due to its

high safety in the event of fire. Multiple sheets of Nomex paper

can be placed on top of each other and glued together at the node locations by

lines of adhesive, which are offset spatially between different layers. This

large stack of Nomex can then be cut into

smaller strips and expanded to form a sheet of Nomex honeycomb.

Alternatively closed cell foams such as Rohacell®

are commonly used for the core, which are denser then there open cell

counterparts but prevent moisture ingress in service and have better mechanical

properties.

Fig. 3. Manufacture of a honeycomb sheet (2)

But what is the advantage of using a sandwich panel?

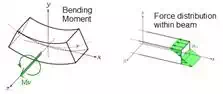

Various structures on an aeroplane are subjected to bending loads.

Essentially the bending of a beam or a plate, by say some sort of pressure

loading over its surface, is equivalent to grabbing the edges and applying a

moment or rotation. Under pure bending Engineer’s bending theory assumes that

the structure resists this moment by a linear variation of stress through its

thickness. Thus, the maximum stresses occur at the top and bottom surfaces, one

being compressive and the other tensile, while the stress at the middle of the

beam thickness is zero. This unstressed location is called the neutral axis.

For pure bending the neutral axis is always located at the centroid of the

cross-section (the mid-plane for a rectangular cross-section) and can be

calculated using the integral expression for the first moment of area.

Therefore we can see that that the structure balances the externally applied

bending moment by an internal force couple of equal magnitude

where the fulcrum of the couple is the location of the neutral axis.

Fig. 4. Bending moment and internal stress distribution of

beam under pure bending (3)

However this linear variation of stress is not very efficient since the

cross-section of the beam is not uniformly stressed i.e. it would be more

efficient if the whole cross-section was constantly loaded by the average

stress to spread out the load. One method to improve the design is to cut-out

the material close to the neutral axis in order to reduce structural mass as

shown in Figure 5. Another possibility is to use a sandwich panel i.e. place

stronger material towards the outside where it is needed and replace the

interior section with a less dense and therefore lighter (and generally weaker)

material to save weight.

Fig. 5. Fuselage frame with flared holes (4)

A major advantage of the sandwich construction compared to the

flared hole design is that the core separates

the stiff outer skins, placing them as far as possible from the neutral axis.

The degree in which a structure prevents deflection in bending is known as the

bending rigidityEI, where E is the Young’s modulus or

stiffness of the material used and I is the second moment of

area. The second moment of area I, which is the bending resistance

of the cross-section, increases the more mass is located away from the neutral

axis. This is analogous to rotational motion where the inertia of rotation

increases the further away the rotating mass is located from the centre of

rotation. In fact, as the name “second moment of area” suggests, the bending

resistance increases with the square of the distance from the neutral axis.

Thus a sandwich panel moves two stiff skins (high values of E such

as Carbon fibre laminates) far away from the central neutral axis in order to

maximise the product EI and therefore create a structure of

incredibly high specific flexural stiffness i.e. high bending stiffness coupled

with minimum mass. The improvements of stiffness versus weight of a sandwich

panel by increasing the separation of the two face sheets is clearly

illustrated in Figure 6. Here the density of the face sheets is assumed to be

15 times higher than that of the core.

Fig. 6. Stiffess vs. weight comparison

for a sandwich panel

Apart from increasing the bending rigidity another advantage of using

sandwich panels is that it actually concentrates the direct bending stresses

(axial ![]() and

shear

and

shear ![]() ) in

the face sheets. This is because when a structure deforms the load always

distributes relative to the stiffness of the different parts. For example, when

two springs are aligned in parallel and fixed on one end by a support and are

displaced by the same extension x on the other end the load

taken by spring 1 will be twice as high as that by spring 2 if

) in

the face sheets. This is because when a structure deforms the load always

distributes relative to the stiffness of the different parts. For example, when

two springs are aligned in parallel and fixed on one end by a support and are

displaced by the same extension x on the other end the load

taken by spring 1 will be twice as high as that by spring 2 if ![]() .

.

Fig. 7. Two springs in parallel (5)

This is equivalent what happens to in a sandwich beam. Since the face

sheets have much higher Young’s modulii than

the low-density core, in bending the large majority of the direct bending loads

is actually taken by the face sheets. This

means that the stress distribution is no longer continuously linear through the

entire cross-section as for an isotropic material in Figure 4, but actually

piecewise linear and discontinuous at the interfaces. For example Figure 8

below clearly indicates how the variation of stress through the thickness of

the sandwich panel changes as the stiffness mismatch between the core and face

sheets is increased. As the modulus of the skins reaches 50 times that of the

core there is a large jump in bending stress from just over zero to about 2

MPa. Compared to the case of equal Young’s modulus this solution is much more

efficient since both the skins and the core are more uniformly stressed. The

limitation of this design is that the large discontinuity of bending stress at

the interface may cause excessive transverse shear stresses at the interface

that can literally pull the face skins away from the core and cause de-bonding

of the two parts. This is why it is important to use a core with high transverse

shear modulus and strength such as honeycomb to absorb these transverse shear

loads. Furthermore, the core transverse shear strength is important for

resisting point or distributed pressure loadings over the surface of the face

sheets and give local support for fasteners.

Fig. 8.

In-plane stress profile through the thickness of a sandwich panel for various

ratios of core-to-face sheet Young’s modulus

Of course there are also many drawbacks of using sandwich panels. For

example when using honeycomb cores it is very hard to form complex curved

shapes using the standard hexagonal matrix shape. This is because honeycomb has

very high values of Poisson’s ratio such that the anti-clastic curvature

effects in bending are quite pronounced. This means that when the honeycomb is

bent to adhere to a certain shape it will form opposite curvature in the

perpendicular direction to form a saddle shape. During in service bending

deformation this will also cause the centre of the core to want to pull away

from the face sheets again leading to excessive transverse shear and normal

stresses at the interface and possible de-bonding of the core and face sheets.

In fact de-bonding may also occur due to impact events or slow moisture ingress

into the open cell honeycomb structure during service. Furthermore, when not

properly designed honeycomb cores may collapse under the external pressure

loading when the sandwich panel is cured in the high-temperature and pressure

oven known as an Autoclave. Some of these drawbacks can be overcome by using

closed-cell forms such as Rohacell®, which have

lower degrees of anti-clastic curvature and, being “closed-cell”, greatly

reduce the danger of water ingress into the core. The drawback of these foams

is that there intrinsic higher density makes them heavier than the equivalent

honeycomb solution. Alternatively, different cellular core configurations other

than honeycomb such as Flex-core, rectangular and square may be used to reduce

the anti-clastic curvature problem.

Fig. 9. Different cellular core styles

In metal construction the analogy to the sandwich beam is the I-beam

seen in many civil constructions. Here the two flanges are located away from

the neutral axis by the vertical web section. The difference in this design is

that the vertical web section does also take considerable direct in-plane loads

since it is of the same material and therefore stiffness as the two flanges.

However, I-beams are much more cost-effective than sandwich beams since they

can be easily mass-produced and do not suffer difficulties such as debonding between the face sheets and the core.

In summary a sandwich comprises,

● two stiff and lightweight face sheets that predominantly take in-plane

stresses and shear loads

● a low-density core that takes transverse shear loads, separates the face

sheets for high bending rigidity, supports the face sheets against buckling modes

forming and can give local support for fastener loads

● an adhesive

holding the entire assembly together which transfer shear loads to the core and

keeps the skins in the correct location.