Developments in Composite Materials

I have just returned from the International Conference for Composite

Materials (ICCM) in Montreal, Canada and would like to share a few observations

and key points about the developments in the composite world that may not be so

easily accessible to a broader audience.

The Great Advance – Applications

ICCM is the biggest conference for composite materials and this year

united over 1500 delegates from academia and different industrial

representatives from the classical sectors aerospace, wind energy and high

performance cars to newer sectors such as mass market cars (e.g. BMW i3),

biomedical applications and even musical instruments. The motto of the

conference “Composite Materials: The Great Advance” aptly captures the current

state of technology in the industry. Since the 1960 considerable amount of

research has been conducted to elucidate the mechanical and chemical

properties of the fibre material, matrix and cured composite under various

conditions such that the global behaviour of these materials is now

sufficiently characterised. This maturity in technology coupled with the ever

decreasing costs and the inherent benefits of high specific stiffness and

strength that fibre-reinforced plastics have to offer, has led to the

increasing application of composite materials in very different industries that

we see today. Thus the “great advance” of composite materials towards wide-spread

use in many industrial sectors.

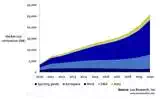

Fig. 1. Composite materials growth broken down by sectors

(1)

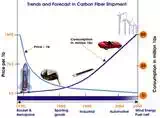

Fig. 2. Carbon Fibre Market (2)

The Great Advance – Novel Technologies

Furthermore, “The Great Advance” also relates to novel composite

materials with much greater complexity that blur the lines between what is a

material and what is a structure. Of course on a macroscopic scale one could

say the steel in a steel bridge is the “material” that has been used to

construct the “structure” that is the bridge. Therefore in this classical

interpretation steel is just the building block to make the bridge, while the

structure itself is the final product that performs a function. However on a

microscopic scale we could argue that steel is a structure in itself since it

is “constructed” of different sized grains that contain different metallic

compounds and is thus an arrangement of small particles i.e. a microstructure.

We could of course continue this argument further and further up to the atomic

scale at which point we have reached the field of nanotechnology. This field of

research has enjoyed much popularity in recent years since by manufacturing our

products from the ground-up, i.e. from the nanoscale to the macroscale, we can

control the properties of our product at multiple length-scales and therefore

tailor the characteristics to be optimal for the desired function in

service or even add some sort of multi-functionality to the

structure/material. Since the material and structure are built at the same time

the dividing line that used to distinguish between these two concepts is

blurred. Even for a simple composite laminate comprised of a stack of

individual layers this divide is no longer so clear since we can define the

properties of each ply in the stacking direction and therefore have control

over one more length scale.

Therefore in the future there will be a great advance towards novel and

multifunctional materials/structures that perform so much more than carrying

structural loads. Currently the design of composite structures is still in some

cases dominated by a “black aluminium” approach. That is taking the current

designs that have worked so well over the last decades using aluminium and

replacing them by an equivalent composite design. The problem with this is that

on one hand the composite material may not be suitable to carry loads in the

same configuration e.g. loads through the thickness have to be avoided to

prevent delaminations. Most importantly however,

such a design approach hinders the greatest advantage of this new material

system, which is to facilitate entirely new structures in terms of

functionality and shape that arise as a results of their inherent properties.

Only by completely re-designing structures from the ground-up and taking the

intricacies of this new material system into consideration can we arrive a new

optimal solutions or conversely ascertain that a metal solution actually works

better under some circumstances. In the following I want to share a few

exciting technologies that you may see in the near future.

1) Variable stiffness technology

This is my field of research and essentially what we are currently doing

is changing the fibre direction over the planform of the plate such that we

have curvilinear fibres rather than the straight fibre laminates that we use

today. In many aerospace applications we require different laminate stacking

sequences in different parts of the structure. Abruptly changing from one

stacking sequence to another can lead to stress concentrations and thus

structurally weaker areas at the interface. Using the variable fibre concept we

can easily spatially blend from one layup to another to reduce these problems.

Furthermore, we can arrange the fibre paths to follow the dominant load paths

as for example around a window in an aircraft fuselage. Loads in a structure

always follow the path of highest stiffness. So by aligning the fibres in the

load direction in supported areas of the laminate (for example the vertical

edges in Fig. 3 below if the load is applied vertically onto the horizontal

edges), a large portion of the stress can be removed from the unsupported

centre of the panel, which can greatly improve the elastic stability of the

structure. This has great potential for future wing structures since the design

of wing skins is greatly governed by local buckling (Fig. 4). It has been shown

that the buckling loads can be improved by 70%-100% using variable stiffness

technology (5), thus the possibility exists to reduce the weight of wing

structures by up to 20% using this technology.

Fig. 3. A variable angle tow laminates (3)

Fig. 4.

Buckling analysis of a stiffened wing panel. The stiffeners break the buckling

mode shapes into smaller wavelengths that require higher energy to form than a

single wave (4)

Another form of various stiffness technology is placing material in

areas where it is needed and removing it from areas where it is not required.

Nature is an expert in achieving this and many of our current design are based

on bio-mimicry. For example, your bones are continuously being re-modelled

based on the stresses that are placed on your skeleton. In this way the density

of your bones is increased in highly-stresses areas and decreased in areas that

are not used so much. In the same way sea-sponge arranges its structure in

a way to achieve the most efficient design. Similarly, wood possesses an

incredibly complex microstructure that is composed of different structural

hierarchies at different length scales. This is similar to a rope where

individual fibres are twisted together to make strands, strands are twisted

together to make bundles, and bundles twisted together to make the complete

rope. This approach of designing at multiple length-scales makes wood very

ductile and resilient to cracks. In this manner attempts have been made to

reproduce such a hierarchical design by arranging short fibres using standing

ultrasonic waves.

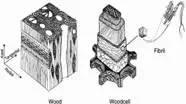

Fig. 5.

Microstructure of wood. Notice the different structures at different length

scales that gives wood its inherent strength (6).

2) Self Healing

Yes, materials can heal themselves. The most popular example is that of

self-healing asphalt, which was presented a few years ago at a TED

conference. In terms of composites 100% recuperation of mechanical properties

have been achieved when the mode of failure has been dominated by matrix

cracks. In high performance composites the matrix is currently some sort of

thermoset or thermoplastic, which allows vascules of

uncured resin to be included in the structure which may break open as a crack

propagates. The uncured resin then permeates through the open crack and cures

in-situ to repair the full functionality of the part. The dissemination of the

healing process can also be achieved using very thin vascules that

are arranged throughout the part. In this manner the structure starts to behave

very much like a living organisms with the vascules serving

as pathways for repair very similar to the veins in an organism. Recently a

great article by the BBC summarised the major achievements in this field.

Fig. 6. Self healing capsules

(7)

Fig. 7. Self healing vascules (7)

3) Nanotechnology

Nanotechnology has been extremely popular during the last 20 years due

to the fact that theoretical predictions promise incredible benefits for almost

all applications in engineering. In terms of advanced composites however, there

are still problems of evenly dispersing nanotubes in resins with agglomeration

or alternatively producing continuous nano-strands

at low costs. In the aerospace industry they show great promise in increasing

the electrical conductivity of laminates to improve their resistance against

lightning-strike, creating structures for magnetic shielding and

providing interlaminar strengthening

using nano-forests.

One of the cooler things I saw at ICCM was research conducted on nano-muscles, which are

essentially nano-fibres that have been twisted

into a rope and can achieve very high actuation forces and strokes at very

little mass.

4) Structural Batteries / Energy Harvesting

Solar power has incredible potential as an energy source since it is the

largest form of energy available for consumption on earth and is limitless.

However, solar power is sporadically dependent on the weather conditions, which

makes energy conversion rather cost intensive and inefficient. However, solar

energy harvesting might find increasing use if actively integrated into

load-bearing components as a multi-functional structure. Bonding thin-film

solar cells onto lightweight composites would eliminate the material redundancy

of stand-alone supporting structures and could easily be integrated into

current laminate manufacturing technology. Photovoltaic (PV) cells have been

imbedded in composite laminates and their performance has not been impeded by

the curing process. However, the performance of the PV cells diminishes rapidly

under static loading since the loading causes cracks

in the cells. Similarly there are ideas to create structural batteries such

that the load carrying chassis of a car can be “charged-up” to additionally

serve as the battery for an electric powertrain. Of course this would have the

great advantage that the heavy batteries used today could be eliminated to some

extent. BAE systems are working on technology to embed battery chemistries

into the carbon fibre fabric.

5) Morphing

Finally, morphing or shape-changing structures have been extensively

studied since the 1970’s for providing aircraft with the possibility of

adapting the shape of their wings to provide the optimal lift for different

flight scenarios. Of course this is to some extent already used in aircraft

with the aid of leading edge slats and trailing-edge flaps to increase the

lift-coefficient for slower flight regimes such as landing and lift-off and in

Formula 1 using drag reduction system of the rear wing. However, slats and flaps

on an aircraft greatly increase the drag of the profile during deployment and

increase the weight of the structure do the heavy actuation mechanism.

Therefore the aim is to design an integral system such as the trailing-edge

design shown below. Other examples of morphing structures include air

intakes for cars, noise-reducing chevrons on jet-engines, or

high-temperature composites used for jet-engine turbine blades that

change there angle of attack based on the

temperature of the airflow around them.

Fig. 8. A morphing trailing edge using a flexible honeycomb

(8).

However, in most cases these technologies are very difficult to apply to

primary aircraft structures. This is because there is a direct conflict between

the high-stiffness, high-strength requirement for carrying loads and the

low-stiffness, large-deflections required for shape-changes. Thus, a driver to

facilitate these technologies will be the development of materials that

change there mechanical properties under

different circumstances.

3) The Great Advance – Solving “big” problems

for larger scale implementation

Finally, one of themes during the conference was trying to solve some of

the major problems faced by the industry hindering further implementation of

current composite technology in all industrial sectors. Of course for some

industries such as mass consumer automobiles the biggest barrier to entry is

cost. The new BMW i3, which will enter the marketplace at the start of 2014,

will cost £30,000+ and is therefore quite a big investment for a small city

vehicle. Of course some of the cost can be attributed to the cost of the

electrical drivetrain and batteries but other manufacturers such as Renault

have shown that a lot of these costs can be reduced by employing a scheme based

on renting batteries rather than buying them with the vehicle. In case of the

i3 a lot of the extra cost is simply down to the fact that BMW are the first to

build a mass produced automobile using a large amount of fibre-reinforced

plastics in primary structural parts. Not only is cost of raw material much

higher than for lightweight metals such as aluminium but the manufacturing

processes and supply chain management required for reliable mass production

were simply not in-place beforehand. Furthermore, a shift in design

methodologies is required since the chemical and mechanical behaviour of

composites is so different from the metal environment that the automobile

industry is so used to dealing with. As an example, proving the structural

integrity for the incredible rigorous crash/impact certification using rather

brittle composite materials compared to more ductile metals is a challenge in

itself. Thus, the relatively high price-tag of the i3 incorporates some of the

research and development costs that BMW have had to face in developing

composite technology for their market sector. No doubt the cost of mass market

composite cars will reduce drastically in the next decade as the raw material

price further reduces and design methodologies and manufacturing processes

mature.

Another major issue hindering the implementation of composites especially

in the aerospace industry is the difficulty of predicting the failure behaviour

of these materials. On problem is the large number of failure modes that may

occur: fibre breakage, matrix cracks, delamination, fibre crimping,

fibre-matrix debonding, global and local

buckling etc. and thus finding accurate failure loads for all these phenomena

under different load cases. Since a larger number of these failure mechanisms

originate on a local, micro-mechanical scale high-fidelity 3D Finite Element

models are often needed to fully understand the mechanisms of failure and

predict the load-carrying capability of different structures. Considering the

size of any commercial aircraft it is absolutely inconceivable to apply such

detailed and computationally expensive analysis tools to every part of an

aircraft. Furthermore, the failure mechanisms are not as well defined as for

metal materials. That is in classical tensile or compressive tests a specimen

may undergo some form of non-linearity that may for a metal specimen be

classified as a failure event but for the composite considerable residual

strength is available. Conversely the failure behaviour of composites can be

very brittle with very little warning compared to the gradual, ductile failure

mechanism of most metals used in the aerospace industry. Considering the

intricacies of composite failure modes and the fact that the individual failure

modes may interact or even change in criticality depending on the size of the

component and environment in which it is used, it is no wonder that currently

very conservative safety factors are being employed for primary composite

aircraft structures that greatly offset the weight-savings that are possible

using this new material system. Thus, one of the biggest if not the biggest

topic in composite structural design for the next couple of years will be the

challenge of developing simple and yet robust failure criteria to be used for

composite designers.