Rocket Science 101: Fuel, engine and nozzle

This is the

third in a series of posts on rocket science. Part I covered the

history of rocketry and Part II dealt with the operating principles

of rockets. If you have not checked out the latter post, I highly recommend you

read this first before diving into what is to follow.

We have

established that designing a powerful rocket means suspending a bunch of highly

reactant chemicals above an ultralight means of combustion. In terms of metrics

this means that a rocket scientist is looking to

● Maximise the mass ratio

to achieve the highest amounts of delta-v. This translates to carrying the

maximum amount of fuel with minimum supporting structure to maximise the

achievable change in velocity of the rocket.

● Maximise the specific

impulse of the propellant. The higher the specific impulse of the fuel the

greater the exhaust velocity of the hot gases and consequently the greater the

momentum thrust of the engine.

● Optimise the shape of

the exhaust nozzle to produce the highest amounts of pressure thrust.

● Optimise the staging

strategy to reach a compromise between the upside of staging in terms of

shedding useless mass and the downside of extra technical complexity involved

in joining multiple rocket engines (such complexity typically adds mass).

● Minimise the dry

mass costs of the rocket either by manufacturing simple expendable rockets at

scale or by building reusable rockets.

These

operational principles set the landscape of what type of rocket we want to

design. In designing chemical rockets some of the pertinent questions we need

to answer are

● What propellants to use

for the most potent reaction?

● How to expel and direct

the exhaust gases most efficiently?

● How to minimise the mass

of the structure?

Here, we will

turn to the propulsive side of things and answer the first of these two

questions.

Propellant

In a chemical

rocket an exothermic reaction of typically two different chemicals is used to

create high-pressure gases which are then directed through a nozzle and

converted into a high-velocity directed jet.

From

the Tsiolkovsky rocket equation we know

that the momentum thrust depends on the mass flow rate of the propellants and

the exhaust velocity,

![]()

The most common types of propellant are:

● Monopropellant: a single

pressurised gas or liquid fuel that disassociates when a catalyst is

introduced. Examples include hydrazine, nitrous oxide and hydrogen peroxide.

● Hypergolic propellant:

two liquids that spontaneously react when combined and release energy without

requiring external ignition to start the reaction.

● Fuel and oxidiser

propellant: a combination of two liquids or two solids, a fuel and an oxidiser,

that react when ignited. Combinations of solid fuel and liquid oxidiser are

also possible as a hybrid propellant system. Typical fuels include liquid

hydrogen and kerosene, while liquid oxygen and nitric acid are often used as

oxidisers. In liquid propellant rockets the oxidiser and fuel are typically

stored separately and mixed upon ignition in the combustion chamber, whereas

solid propellant rockets are designed premixed.

Rockets can

of course be powered by sources other than chemical reactions. Examples of this

are smaller, low performance rockets such as attitude control thruster, that

use escaping pressurised fluids to provide thrust. Similarly, a rocket may be

powered by heating steam that then escapes through a propelling nozzle.

However, the focus here is purely on chemical rockets.

Solid propellants

Solid

propellants are made of a mixture of different chemicals that are blended into

a liquid, poured into a cast and then cured into a solid. At its simplest,

these chemical blends or “composites” are comprised of four different

functional ingredients:

● Solid oxidiser granules.

● Flakes or powders of exothermic compounds.

● Polymer binding agent.

● Additives to stabilise or modify the burn rate.

Gunpowder is

an example of a solid propellant that does not use a polymer binding agent to

hold the propellant together. Rather the charcoal fuel and potassium nitrate

oxidiser are compressed to hold their shape. A popular solid rocket fuel is

ammonium perchlorate composite propellant (APCP) which uses a mixture of 70%

granular ammonium perchlorate as an oxidiser, with 20% aluminium powder as a

fuel, bound together using 10% polybutadiene acrylonitrile (PBAN).

Solid propellant rocket components (via Wikimedia Commons URL)

Solid

propellant rockets have been used much less frequently than liquid fuel

rockets. However, there are some advantages, which can make solid propellants

favourable to liquid propellants in some military applications (e.g.

intercontinental ballistic missiles, ICBMs). Some of the advantages of solid

propellants are that:

● They are easier to store

and handle.

● They are simpler to

operate with.

● They have less

components. There is no need for a separate combustion chamber and turbo pumps

to pump the propellants into the combustion chamber. The solid propellant (also

called “grain”) is ignited directly in the propellant storage casing.

● They are much denser

than liquid propellants and therefore reduce the fuel tank size (lower mass).

Furthermore, solid propellants can be used as a load-bearing component, which

further reduces the structural weight of the rocket. The cured solid propellant

can readily be encased in a filament-wound composite rocket shell, which has

more favourable strength-to-weight properties of the metallic rocket shells

typically used for liquid rockets.

Apart from

their use as ICBMs, solid rockets are known for their role as boosters. The

simplicity and relatively low cost compared with liquid-fuel rockets means that

solid rockets are a better choice when large amounts of cheap additional thrust

is required. For example, the Space Shuttle used two solid rocket boosters to complement

the onboard liquid propellant engines.

The

disadvantage of solid propellants is that their specific impulse, and hence the

amount of thrust produced per unit mass of fuel, is lower than for liquid

propellants. The mass ratio of solid rockets can actually be greater than that

of liquid rockets as a result of the more compact design and lower structural

mass, but the exhaust velocities are much lower. The combustion process in

solid rockets depends on the surface area of the fuel, and as such any air

bubbles, cracks or voids in the solid propellant cast need to be prevented.

Therefore, quite expensive quality assurance measures such as ultrasonic

inspection or x-rays are required to assure the quality of the cast. The second

problem with air bubbles in the cast is that the amount of oxidiser is

increased (via the oxygen in the air) which results in local temperature hot

spots and increased burn rate. Such local imbalances can spiral out of control

to produce excessive temperatures and pressures, and ultimately lead to

catastrophic failure. Another disadvantage of solid propellants are their

binary operation mode. Once the chemical reaction has started and the engines

have been ignited, it is very hard to throttle back or control the reaction.

The propellant can be arranged in a manner to provide a predetermined thrust

profile, but once this has started it is much hard to make adjustments on the

fly. Liquid propellant rockets on the other hand use turbo pumps to throttle

the propellant flow.

Liquid propellants

Liquid

propellants have more favourable specific impulse measures than solid rockets.

As such they are more efficient at propelling the rocket for a unit mass of

reactant mass. This performance advantage is due to the superior oxidising

capabilities of liquid oxidisers. For example, traditional liquid oxidisers

such as liquid oxygen or hydrogen peroxide result in higher specific impulse

measures than the ammonium perchlorate in solid rockets. Furthermore, as the

liquid fuel and oxidiser are pumped into the combustion chamber, a

liquid-fuelled rocket can be throttled, stopped and restarted much like a car

or a jet engine. In liquid-fuelled rockets the combustion process is restricted

to the combustion chamber, such that only this part of the rocket is exposed to

the high pressure and temperature loads, whereas in solid-fuelled rockets the

propellant tanks themselves are subjected to high pressures. Liquid propellants

are also cheaper than solid propellants as they can be sourced from the upper

atmosphere and require relatively little refinement compared to the composite

manufacturing process of solid propellants. However, the cost of the propellant

only accounts for around 10% of the total cost of the rocket and therefore

these savings are typically negligible. Incidentally, the high proportion of

costs associated with the structural mass of the rocket is why re-usability of

rocket stages is such an important factor in reducing the cost of spaceflight.

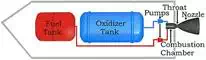

Schematic of a liquid-fuelled rocket (via Wikimedia Commons)

The main

drawback of liquid propellants is the difficulty of storage. Traditional liquid

oxidisers are highly reactive and very toxic such that they need to be handled

with care and properly insulated from other reactive materials. Second, the

most common oxidiser, liquid oxygen, needs to be stored at very low cryogenic

temperatures and this increases the complexity of the rocket design. What is

more, additional components such as turbopumps and

the associated valves and seals are needed that are entirely absent from

solid-fuelled rockets.

Modern spaceflight is dominated by two liquid propellant mixtures:

1. Liquid

oxygen (LOX) and kerosene (RP-1): As discussed in the previous post this

mix of oxidiser and fuel is predominantly used for lower stages (i.e. to get

off the launch pad), due to the higher density of kerosene compared to liquid

hydrogen. Kerosene, as a higher density fuel, allows for better ratios of

propellant to tankage mass which is favourable for the mass ratio. Second, high

density fuels work better in an atmospheric pressure environment. Historically,

the Atlas V, Saturn V and Soyuz rockets have used LOX and RP-1 for the first

stages and so does the SpaceX Falcon rocket today.

2. Liquid

oxygen and liquid hydrogen: This combination is mostly used for the upper

stages that propel a vehicle into orbit. The lower density of the liquid

hydrogen requires higher expansion ratios (gas pressure – atmospheric pressure)

and therefore works more efficiently at higher altitudes. The Atlas V, Saturn V

and modern Delta family or rockets all used this propellant mix for the upper

rocket stages.

The choice of propellant mixture for different stages requires

certain tradeoffs. Liquid hydrogen provides

higher specific impulse than kerosene, but its density is around 7 times lower

and therefore liquid hydrogen occupies much more space for the same mass of

fuel. As a result, the required volume and associated mass of tankage, fuel

pumps and pipes is much greater. Both the the specific

impulse of the propellant and tankage mass influence the potential delta-v of

the rocket, and hence liquid hydrogen, chemically the more efficient fuel, is

not necessarily the best option for all rockets.

Although the exact choice of fuel is not straightforward I will propose

two general rules of thumb that explain why kerosene is used for the early

stages and liquid hydrogen for the upper stages:

1. In

general, the denser the fuel the heavier the rocket on the launch pad. This

means that the rocket needs to provide more thrust to get off the ground and it

carries this greater amount of thrust throughout the entire duration of the

burn. As fuel is being depleted, the greater thrust of denser fuel rockets

means that the rocket reaches orbit earlier and as a result minimises drag

losses in the atmosphere.

2. Liquid

hydrogen fuelled rockets generally produce the lightest design and are

therefore used on those parts of the spacecraft that actually need to be

propelled into orbit or escape Earth’s gravity to venture into deep space.

Engine and Nozzle

In combustive

rockets, the chemical reaction between the fuel and oxidiser creates a high

temperature, high pressure gas inside the combustion chamber. If the combustion

chamber were closed and symmetric, the internal pressure acting on the chamber

walls would cause equal force in all directions and the rocket would remain

stationary. For anything interesting to happen we must therefore open one end of

the combustion chamber to allow the hot gases to escape. As a result of the hot

gases pressing against the wall opposite to the opening, a net force in the

direction of the closed end is induced.

Net thrust produced by rocket (via Wikimedia Commons)

Rocket

pioneers, such as Goddard, realised early on that the shape of the nozzle is of

crucial importance in creating maximum thrust. A converging nozzle

accelerates the escaping gases by means of the conservation of mass. However,

converging nozzles are fundamentally limited to fluid flows of Mach 1, the

speed of sound, and this is known as the choke condition. In this case, the

nozzle provides relatively little thrust and the rocket is purely propelled by

the net force acting on the close combustion chamber wall.

To further accelerate

the flow, a divergent nozzle is required at the choke point. A

convergent-divergent nozzle can therefore be used to create faster fluid flows.

Crucially, the Tsiolkovsky rocket equation

(conservation of momentum) indicates that the exit velocity of the hot gases is

directly proportional to the amount of thrust produced. A second advantage is

that the escaping gases also provide a force in the direction of flight by

pushing on the divergent section of the nozzle.

Underexpanded, perfectly expanded, over

expanded and grossly overexpanded de Laval

nozzles (via Wikimedia Commons).

The exit

static pressure of the exhaust gases, i.e. the pressure of the gases if the

exhaust jet was brought to rest, is a function of the pressure created inside

the combustion chamber and the ratio of throat area to exit area of the nozzle.

If the exit static pressure of the exhaust gases is greater than the

surrounding ambient air pressure, the nozzle is known to be underexpanded. On the other hand, if the exit static

pressure falls below the ambient pressure then the nozzle is known to be overexpanded. In this case two possible scenarios are

possible. The supersonic air flow exiting the nozzle will induce a shock wave

at some point along the flow. As the exhaust gas particles travel at speeds

greater than the speed of sound, other gas particles upstream cannot “get out

of the way” quickly enough before the rest of the flow arrives. Hence, the

pressure progressively builds until at some point the properties of the fluid,

density, pressure, temperature and velocity, change instantaneously. Thus,

across the shock wave the gas pressure of an overexpandednozzle

will instantaneously shift from lower than ambient to exactly ambient pressure.

If shock waves, visible by shock diamonds, form outside the nozzle, the nozzle

is known as simply overexpanded. However,

if the shock waves form inside the nozzle this is known asgrossly overexpanded.

In an ideal

world a rocket would continuously operate at peak efficiency, the condition

where the nozzle is perfectly expanded throughout the entire flight. This can

intuitively be explained using the rocket thrust equation introduced in

the previous post:

![]()

Peak

efficiency of the rocket engine occurs when ![]() such that the

pressure thrust contribution is equal to zero. This is the condition of peak

efficiency as the contribution of the momentum thrust is maximised while

removing any penalties from over- orunderexpanding the

nozzle. An underexpanded nozzle means

that

such that the

pressure thrust contribution is equal to zero. This is the condition of peak

efficiency as the contribution of the momentum thrust is maximised while

removing any penalties from over- orunderexpanding the

nozzle. An underexpanded nozzle means

that ![]() , and while this

condition provides extra pressure thrust,

, and while this

condition provides extra pressure thrust, ![]() is lower and some of the energy that has gone into

combusting the gases has not been converted into kinetic energy. In anoverexpanded nozzle the pressure differential is

negative,

is lower and some of the energy that has gone into

combusting the gases has not been converted into kinetic energy. In anoverexpanded nozzle the pressure differential is

negative, ![]() . In this case,

. In this case, ![]() is fully developed but the overexpansion induces a drag

force on the rocket. If the nozzle is grossly overexpanded such

that a shock wave occurs inside the nozzle,

is fully developed but the overexpansion induces a drag

force on the rocket. If the nozzle is grossly overexpanded such

that a shock wave occurs inside the nozzle, ![]() may still be greater than

may still be greater than ![]() but the supersonic jet separates from

the divergent nozzle prematurely (see diagram below) such that

but the supersonic jet separates from

the divergent nozzle prematurely (see diagram below) such that ![]() decreases. In outer space

decreases. In outer space ![]() decreases and therefore the thrust

created by the nozzle increases. However,

decreases and therefore the thrust

created by the nozzle increases. However, ![]() is also decreasing as the flow separates earlier from

the divergent nozzle. Thus, some of the increased efficiency of reduced ambient

pressure is negated.

is also decreasing as the flow separates earlier from

the divergent nozzle. Thus, some of the increased efficiency of reduced ambient

pressure is negated.

A perfectly

expanded nozzle is only possible using a variable throat area or variable exit

area nozzle to counteract the ambient pressure decrease with gaining altitude.

As a result, fixed area nozzles become progressively underexpanded as

the ambient pressure decreases during flight, and this means most nozzles are

grossly overexpanded at takeoff. Some various exotic nozzles such as plug

nozzles, stepped nozzles and aerospikes have been proposed to adapt

to changes in ambient pressure and increasing thrust at higher altitudes. The

extreme scenario obviously occurs once the rocket has left the Earth’s atmosphere.

The nozzle is now so grossly overexpanded that

the extra weight of the nozzle structure outweighs any performance gained from

the divergent section.

Thus we can

see that just as in the case of the propellants the design of individual

components is not a straightforward matter and requires detailed tradeoffs between different configurations. This is

what makes rocket science such a difficult endeavour.