The DeHavilland Comet Crash

(Photo Comet)

The DeHavilland Comet was the first production commercial

jet airliner that went into service in 1952. The earliest production aircraft

designated G-ALYP was loaned to the British Overseas Airways Company and

inaugurated the first scheduled overseas flight from London to Johannesburg

with fare-paying customers on-board. Much of the design is similar to the

commercial airliners seen around the world today. The Comet had four turbojet

engines (turbofan are now the norm for reduced noise and better fuel economy),

which made the aircraft much more efficient at higher altitudes of flight than

its propeller-driven contemporaries. Furthermore, it featured an internally

pressurised fuselage/cabin and also pioneered design elements which were

unusual at the time such as backward-swept wings, integral wing fuel tanks and

a four-wheel bogie undercarriage (1). Unfortunately, the DeHavilland Comet also influenced modern aircraft

design by two catastrophic failures.

Within two

years of entering service two of the Comet fleet fell apart during ascent to

cruise altitude with a total loss of the aircrafts and the death of 56

passengers. The first production aircraft G-ALYP, scheduled on BOAC Flight 781

from Rome Ciampino to London Heathrow, was

lost on January 10, 1954 by the fuselage breaking up in mid-air 20 minutes

after taking off. BOAC voluntarily grounded its fleet and engineers suggested

60 immediate modifications to the design to rectify some of the design flaws

that were believed to have caused the accident (2). Comet flights resumed on

March 23, 1954 but only two weeks later on April 8, 1954 Comet G-ALYY, on the

chartered South African Airways Flight 201 from Rome Ciampino to

Cairo, again crashed into the Mediterranean sea within

30 minutes of take-off. The entire Comet 1 fleet was then grounded, its

Certificate of Airworthiness revoked and the line production at DeHavilland in Hatfield suspended.

A number of

investigations followed led by Sir Arnold Hall at the Royal Aeronautical

Establishment in Farnborough, UK. Most critically this included a full-scale

cyclic internal pressurisation test of the fuselage in a water tank of the

aircraft G-ALYU removed from service for this purpose. G-ALYU had accumulated

1221 internal pressurisation cycles in service and after a further 1836 cycles

in the water tank the cabin ripped open after a proof-test loading 33% higher

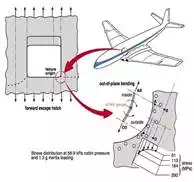

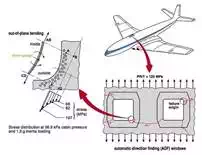

than the nominal pressurisation cycle loading (2). Evidence of fatigue cracking

was found that originated from the aft lower corner of the forward escape hatch

and also from the right-hand aft corner of the windows illustrated in Figures 1

and 2 below.

Fig. 1.

Failure origin in Comet G-ALYU around escape hatch (1, 2).

Fig. 2.

Failure origin of Comet G-ALYU around square windows (1, 2).

Both of these

locations feature sharp right hand corners which cause local areas of high

stress-concentration that provide very benign conditions for crack initiation

and propagation under fatigue loading. Furthermore, circular cylindrical

structures, such as the aircraft fuselage, develop internal membrane stresses

(constant through the thickness) to resist the internal pressure loads. As a

result of the curved shape of the fuselage these forces induce secondary

out-of-plane bending moments acting to “straighten-out” the curvature. In

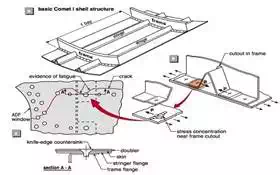

addition, the stress concentration around the the escape

hatch and window cutouts was exacerbated by

countersunk bolt holes creating a “knife-edge” in both the primary skin and

doubler reinforcement (Figure 3) (2). Swift (1987) has argued that the shell

structure would have had enough residual strength to sustain large and easily

detectable cracks if they had grown midway between two window cutouts. However, cracks that grew across a bay from

one cutout to the next would not be

tolerable and result in ultimate failure of the structure.

Fig. 3.

Failure origin of Comet G-ALYU around countersunk bolt holes (1, 2).

Lessons Learned

The most

notable lesson learned from the Comet disaster is that viewing windows are no

longer designed square but with rounded edges to reduce any stress

concentrations. Another immediate lessons is that crack-stoppers are now placed

between frame-cutouts that take the shape of

circumferential stiffeners that break-up the fuselage into multiple sections

and thus prevent the crack from propagating from one window to the next. Most

importantly however, before and during the Comet era the aircraft design

philosophy was predominantly SAFE-LIFE, which means that the structure was

designed to sustain the required fatigue life with no initial damage and no

accumulation of damage during service e.g. cracking (1). The Comet accidents

showed that around stress concentration cracks would initiate and propagate

much earlier than expected, such that safety could not be universally

guaranteed in the SAFE-LIFE approach without uneconomically short aircraft

service lives.

For this

reason the FAIL-SAFE design philosophy was developed in the late 1950’s. All

materials are assumed to contain a finite initial defect size before entering

service that may grow due to fatigue loading in-service. The aircraft structure

is thus designed to sustain structural damage without compromising safety up to

a critical damage size that can be easily detected by visual inspection between

flights. All inspections are coupled with crack propagation calculations that

guarantee that an observed crack is not susceptible to grow to the critical

size between two inspection cycles, in which case adequate repair is performed.

Furthermore, the structure is designed to be damage tolerant with

multiple load paths and built-in redundancies that impart residual

strength to the aircraft in case the primary structure is compromised

in-service.