Jet Engine Detail Design - The Compressor

In

this topic the design of jet engine compressors will be discussed leading to

the definition of ballpark performance parameters. For smaller engines

centrifugal (CF) compressors are used since they can handle smaller flow rates

more effectively and are more compact than axial compressors. Axial compressors

however have the advantage of a smaller frontal area for a given flow rate, can

handle higher flow rates and generally have higher efficiencies than CF

compressors. For larger turbines used on civil aircraft the most suitable

compressor and turbine will be of the axial type. Early axial compressors were

able to raise the pressure of the incoming area around 5-fold, while modern

turbofan engines have pressure ratios in excess of 30:1.

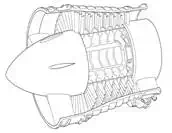

Low pressure axial compressor scheme of the

Olympus BOl.1 turbojet. (Photo Credit: Wikipedia)

Because

the pressure rises in the direction of flow through the compressor there is an

acute risk of the boundary layers separating on the compressor blades as they

encounter this adverse pressure gradient. When this happens the performance of

the compressor drops dramatically and compressor is said to stall. For this

reason the compression is spread over a large number of compressor stages such

that the smaller incremental increases in pressure across each stage allow

engineers to obtain a large overall pressure ratio without incurring stall. A

stage consists of a row of rotating blades called the rotor and

a row of stationary blades called the stator. Each of these rows

may consist of between 30-100 distinct blades and there may be up to 20 stages

between the air inlet and compressor outlet. The role of the rotor blades is to

accelerate the incoming air in order to increase the kinetic energy of the

fluid. Across the stators the fluid is then decelerated and as a consequence

the fluid pressure is increased. As the pressure and density increase across

each stage the overall flow velocity is kept relatively constant by reducing

the height of the blades from stage to stage. Thus the compressor tapers down

from inlet to outlet.

In

an attempt to reduce the number of compressor stages for a more compact engine,

a designer’s goal is to maximise the pressure ratio across each stage. The

stage pressure ratio R is given by the following expression,

![]()

Where ![]() is the stage isentropic efficiency, T01 is

the total (stagnation) temperature, U the rotary speed of the

compressor, Cathe axial speed of the

fluid, cp the coefficient of latent

fusion at constant pressure, and b1 and b2 the angle of the rotor blade leading

and trailing edge relative to the axial flow direction.

is the stage isentropic efficiency, T01 is

the total (stagnation) temperature, U the rotary speed of the

compressor, Cathe axial speed of the

fluid, cp the coefficient of latent

fusion at constant pressure, and b1 and b2 the angle of the rotor blade leading

and trailing edge relative to the axial flow direction.

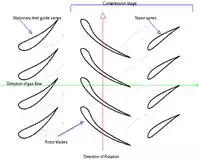

Diagram

of an axial flow compressor.

The

pressure ratio across each stage can be maximised by increasing the rotary

speed of the compressor U, the angle through which the fluid is

turned across the rotor blades tan b1 –tan b2 and the axial speed of the

fluid Ca through the compressor. However there is a limit on

the extent of these three parameters.

1. The blade tip speed and therefore U is

limited by stress considerations at the root. If the fan is assumed to be of

constant cross-sectional area then the centrifugal stress at the root is given

by,

![]()

Where Ut is the tip speed, ![]() is the density of the blade, and the

ratio rr/rt is

called the root-to-tip ratio of the blade. To prevent the blades from detaching

from the hub and destroying the engine this root stress is not allowed to

exceed a certain proof stress. It can be seen that the root stress is

proportional to the square of the compressor rotational velocity and decreases

as the blade length becomes shorter. Since the first compressor blades have the

highest blade lengths they limit the maximum tip speed and therefore the

efficiency of the compressor. It is therefore common to split the compressor

into double or triple spool configurations such as a large fan, intermediate-pressure

and high-pressure compressors that are rotating at three different speeds. In

this manner the large diameter fan can rotate at lower speeds to satisfy the

stress restrictions while the shorter blade high-pressure compressor may rotate

at higher speeds.

is the density of the blade, and the

ratio rr/rt is

called the root-to-tip ratio of the blade. To prevent the blades from detaching

from the hub and destroying the engine this root stress is not allowed to

exceed a certain proof stress. It can be seen that the root stress is

proportional to the square of the compressor rotational velocity and decreases

as the blade length becomes shorter. Since the first compressor blades have the

highest blade lengths they limit the maximum tip speed and therefore the

efficiency of the compressor. It is therefore common to split the compressor

into double or triple spool configurations such as a large fan, intermediate-pressure

and high-pressure compressors that are rotating at three different speeds. In

this manner the large diameter fan can rotate at lower speeds to satisfy the

stress restrictions while the shorter blade high-pressure compressor may rotate

at higher speeds.

However

the rotational speed of the fan is typically constrained by more stringent

stress considerations. In a turbofan engine the large diameter fan at the front

of the engine acts as a single-stage compressor. In modern turbofan engines the

fan divides the flow with most of the air going to the bypass duct to a

propelling nozzle and only a small portion going into the core. The high root

stresses caused by the long fan blades are often exacerbated by bird strikes.

For mechanical reasons a lower limit of root-to-tip ratio of 0.35 is often

employed. The flow impinging onto the fan is also at a very high Mach number

since the cruising speed of civil aircraft is typically around M = 0.83.

Supersonic flow inevitably terminates in a shock wave with a resulting increase

in pressure and entropy over the compressor blades. Shock waves reduce the

efficiency of the compressor blades since they disturb the flow over the

profile that lead to boundary layer separation. Furthermore, these shock waves

may cause unwanted vibrations of the fan blades that further reduce the

efficiency of the compressor and increase noise. Therefore for reasons of

efficiency, reducing noise and limiting the damage of bird strikes the tip

speed of the fan is restricted, typically a relative Mach number of 1.6 is

considered as the upper limit.

2. The axial speed Ca has to be maximised

to optimise the pressure ratio and reduce the frontal area of the engine.

Similar to the argument given above the axial speed is typically limited by

compressibility effects of supersonic flow. As the pressure, static temperature

and therefore the speed of sound increases from stage to stage, the

compressibility effects are worst in the first stages. For the first stage the

air enters axially such that by adding the orthogonal velocity vectors U and Cawe get V2 = U2 +

Ca2 where V is the speed relative to the

blade. In modern engines V may be in the transonic region

incurring quite large losses. In this respect twin-spool engines have the

advantage that the lower-pressure compressor rotates at a lower speed, which

reduces the compressibility problem.

3. The angle through which the fluid is turned across the

rotor blades b is limited by the growth of the boundary

layers. Compressor blades are aerofoils that function in the same manner as

aeroplane wings. Therefore as the angle of attack or camber of aerofoil is

increased to increase the rotation of the flow velocity vector, the adverse

pressure gradient across the suction surface increases, until at some point the

boundary layer separates. As the boundary layer separates the effective turning

angle b is reduced such that the total pressure increase

across the stage reduces.

The

limits of U, Ca and b1 – b2 all place limits on

the maximum pressure ratio that can be achieved in an axial compressor. Typical

examples are U ≈ 350 m/s, Ca = 200 m/s, b1 – b2

< 45°.

Compressor

blades are typically quite thin and are constructed from lightweight metallic

alloys such as aluminium and titanium. The compressor blades feature an

aerofoil section as shown in the Figure below. The centrifugal forces that act

on the airflow are balanced by high-pressure air towards the tip of the blade.

In order to obtain this higher pressure towards the tip the blade must be

twisted from root to tip in order to change the angle of incidence on the flow,

and therefore control the pressure variation over the blade.