Working cycle and airflow

The gas turbine engine is essentially a heat engine using air as a working fluid to provide thrust. To achieve this, the air passing through the engine has to be accelerated; this means that the velocity or kinetic energy of the air is increased. To obtain this increase, the pressure energy is first of all increased, followed by the addition of heat energy, before final conversion back to kinetic Energy in the form of a high velocity jet efflux.

Working Cycle

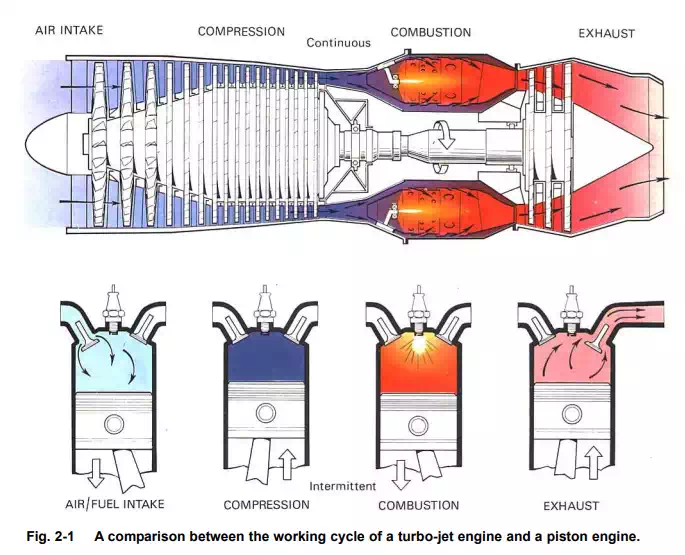

The working cycle of the gas turbine engine is similar to that of the four-stroke piston engine. However, in the gas turbine engine, combustion occurs at a constant pressure, whereas in the piston engine it occurs at a constant volume. Both engine cycles (fig. 2-1) show that in each instance there is induction, compression, combustion and exhaust. These processes are intermittent in the case of the piston engine whilst they occur continuously in the gas turbine. In the piston engine only one stroke is utilized in the production of power, the others being involved in the charging, compressing and exhausting of the working fluid. In contrast, the turbine engine eliminates the three 'idle' strokes, thus enabling more fuel to be burnt in a shorter time; hence it produces a greater power output for a given size of engine.

Due to the continuous action of the turbine engine and the fact that the combustion chamber is not an enclosed space, the pressure of the air does not rise, like that of the piston engine, during combustion but its volume does increase. This process is known as heating at constant pressure. Under these conditions there are no peak or fluctuating pressures to be withstood, as is the case with the piston engine with its peak pressures in excess of 1,000 lb. per sq. in. It is these peak pressures which make it necessary for the piston engine to employ cylinders of heavy construction and to use high octane fuels, in contrast to the low octane fuels and the light fabricated combustion chambers used on the turbine engine.

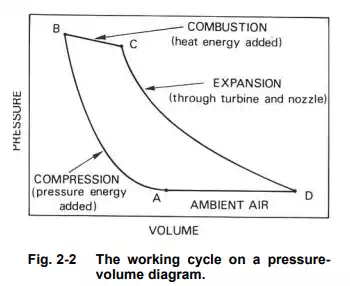

The working cycle upon which the gas turbine engine functions is, in its simplest form, represented by the cycle shown on the pressure volume diagram in fig. 2-2. Point A represents air at atmospheric pressure that is compressed along the line AB. From B to C heat is added to the air by introducing and burning fuel at constant pressure, thereby considerably increasing the volume of air. Pressure losses in the combustion chambers (Part 4) are indicated by the drop between B and C. From C to D the gases resulting from combustion expand through the turbine and jet pipe back to atmosphere. During this part of the cycle, some of the energy in the expanding gases is turned into mechanical power by

the turbine; the remainder, on its discharge to atmosphere, provides a propulsive jet.

Because the turbo-jet engine is a heat engine, the higher the temperature of combustion the greater is the expansion of the gases. The combustion temperature, however, must not exceed a value that gives a turbine gas entry temperature suitable for the design and materials of the turbine assembly.

The use of air-cooled blades in the turbine assembly permits a higher gas temperature and a consequently higher thermal efficiency.

The Relations Between Pressure, Volume and Temperature

During the working cycle of the turbine engine, the airflow or 'working fluid' receives and gives up heat, so producing changes in its pressure, volume and temperature. These changes as they occur are closely related, for they follow a common principle that is embodied in a combination of the laws of Boyle and Charles. Briefly, this means that the product of the pressure and the volume of the air at the various stages in the working cycle is proportional to the absolute temperature of the air at those

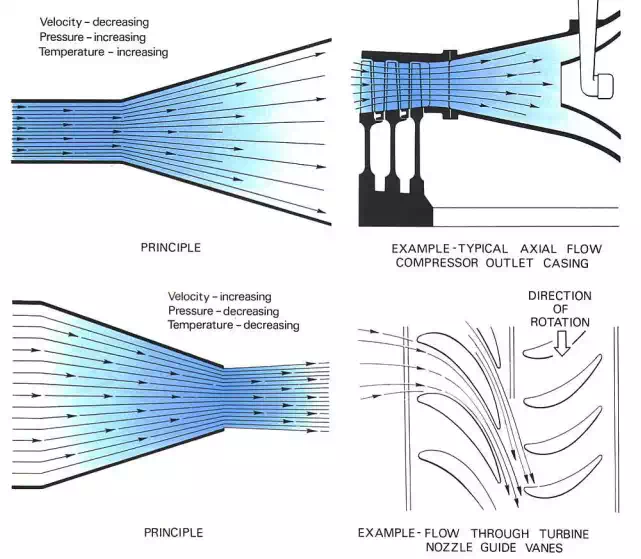

Fig. 2-3 An airflow through divergent and convergent ducts

stages. This relationship applies for whatever means are used to change the state of the air. For example, whether energy is added by combustion or by compression, or is extracted by the turbine, the heat change is directly proportional to the work added or taken from the gas.

There are three main conditions in the engine working cycle during which these changes occur. During compression, when work is done to increase the pressure and decrease the volume of the air, there is a corresponding rise in the temperature. During combustion, when fuel is added to the air and burnt to increase the temperature, there is a corresponding increase in volume whilst the pressure remains almost constant. During expansion, when work is taken from the gas stream by the turbine assembly, there is a decrease in temperature and pressure with a corresponding increase in volume.

Changes in the temperature and pressure of the air can be traced through an engine by using the airflow diagram in fig. 2-5. With the airflow being continuous, volume changes are shown up as changes in velocity.

The efficiency with which these changes are made will determine to what extent the desired relations between the pressure, volume and temperature are attained. For the more efficient the compressor, the higher the pressure generated for a given work input; that is, for a given temperature rise of the air. Conversely, the more efficiently the turbine uses the expanding gas, the greater the output of work for a given pressure drop in the gas.

When the air is compressed or expanded at 100 per cent efficiency, the process is said to be adiabatic. Since such a change means there is no energy losses in the process, either by friction, conduction or turbulence, it is obviously impossible to achieve in practice; 90 per cent is a good adiabatic efficiency for the compressor and turbine.