Accessory drives

Accessory units provide the power for aircraft hydraulic, pneumatic and electrical systems in addition to providing various pumps and control systems for efficient engine operation. The high level of dependence upon these units requires an extremely reliable drive system.

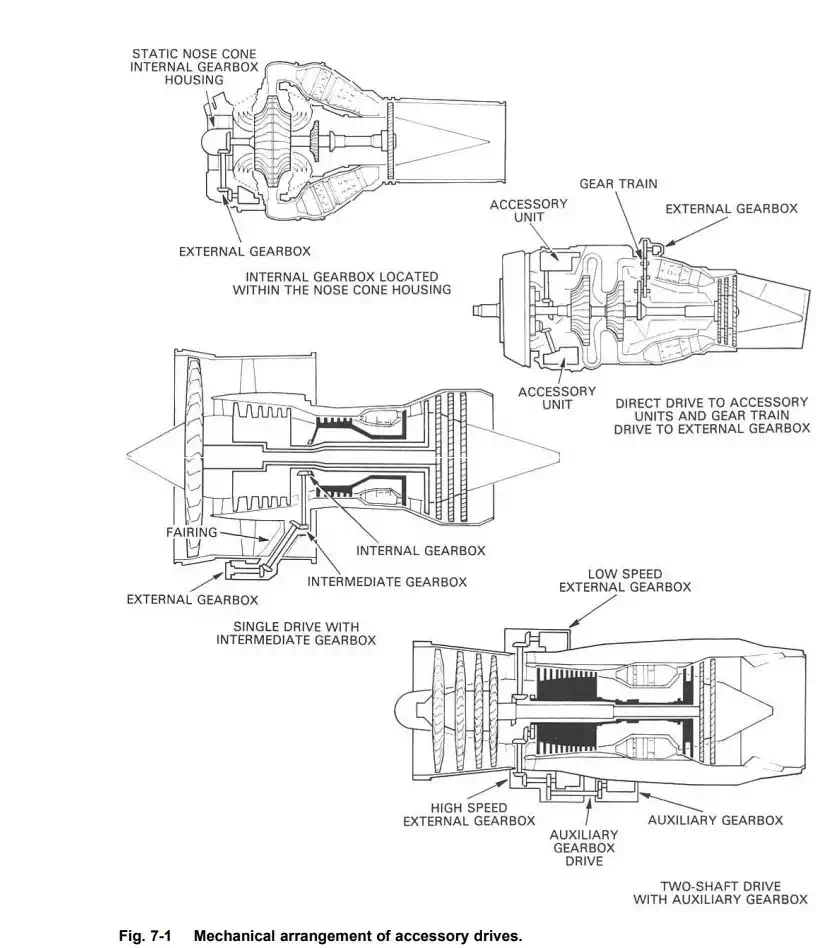

The drive for the accessory units is typically taken from a rotating engine shaft, via an internal gearbox, to an external gearbox which provides a mount for the accessories and distributes the appropriate geared drive to each accessory unit. A starter may also be fitted to provide an input torque to the engine. An accessory drive system on a high by-pass engine takes between 400 and 500 horsepower from the engine.

Gearboxes and Drives

Internal gearbox

The location of the internal gearbox within the core of an engine is dictated by the difficulties of bringing a driveshaft radially outwards and the space available within the engine core.

Thermal fatigue and a reduction in engine performance, due to the radial driveshaft disturbing the gasflow, create greater problems within the turbine area than the compressor area. For any given engine, which incorporates an axial-flow compressor, the turbine area is smaller than that containing the compressor and therefore makes it physically easier to mount the gearbox within the compressor section. Centrifugal compressor engines can have limited available space, so the internal gearbox may be located within a static nose cone or, in the case of a turbo-propeller engine, behind the propeller reduction gear as shown in fig. 7-1.

On multi-shaft engines, the choice of which compressor shaft is used to drive the internal gearbox is primarily dependent upon the ease of engine starting. This is achieved by rotating the compressor shaft, usually via an input torque from the external gearbox. In practice the high pressure system is invariably rotated in order to generate an airflow through the engine and the high pressure compressor shaft is therefore coupled to the internal gearbox.

To minimize unwanted movement between the compressor shaft bevel gear and radial driveshaft bevel gear, caused by axial movement of the compressor shaft, the drive is taken by one of three basic methods (fig. 7-2). The least number of components is used when the compressor shaft bevel gear is mounted as close to the compressor shaft location bearing as possible, but a small amount of movement has to be accommodated within the meshing of the bevel gears. Alternatively, the compressor shaft bevel gear may be mounted on a stub shaft which has its own location bearing. The stub shaft is splined onto the compressor shaft which allows axial movement without affecting the bevel gear mesh. A more complex system utilizes an idler gear which meshes with the compressor shaft via straight spur gears, accommodating the axial movement, and drives the radial driveshaft via a bevel gear arrangement. The latter method was widely employed on early engines to overcome gear engagement difficulties at high speed.

To spread the load of driving accessory units, some engines take a second drive from the slower rotating low pressure shaft to a second external gearbox (fig. 7-1). This also has the advantage of locating the accessory units in two groups, thus overcoming the possibility of limited external space on the engine. When this method is used, an attempt is made to group the accessory units specific to the engine onto the high pressure system, since that is the first shaft to rotate, and the aircraft accessory units are driven by the low pressure system. A typical internal gearbox showing how both drives are taken is shown in fig. 7-3.