Turbine blades

A brief mention of some of the points to be considered in connection with turbine blade design will give an idea of the importance of the correct choice of blade material. The blades, while glowing red-hot, must be strong enough to carry the centrifugal loads due to rotation at high speed. A small turbine blade weighing only two ounces may exert a load of over two tons at top speed and it must withstand the high bending loads applied by the gas to produce the many thousands of turbine horsepower necessary to drive the compressor. Turbine blades must also be resistant to fatigue and thermal shock, so that they will not fail under the influence of high frequency fluctuations in the gas conditions, and they must also be resistant to corrosion and oxidization. In spite of all these demands, the blades must be made in a material that can be accurately formed and machined by current manufacturing methods.

From the foregoing, it follows that for a particular blade material and an acceptable safe life there is an associated maximum permissible turbine entry temperature and a corresponding maximum engine power. It is not surprising, therefore, that metallurgists and designers are constantly searching for better turbine blade materials and improved methods of blade cooling.

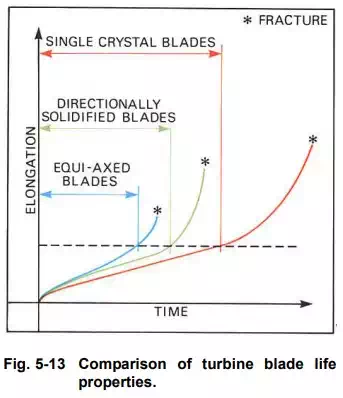

Over a period of operational time the turbine blades slowly grow in length. This phenomenon is known as 'creep' and there is a finite useful life limit before failure occurs.

The early materials used were high temperature steel forgings, but these were rapidly replaced by cast nickel base alloys which give better creep and fatigue properties.

Close examination of a conventional turbine blade reveals a myriad of crystals that lie in all directions (equi-axed). Improved service life can be obtained by aligning the crystals to form columns along the blade length, produced by a method known as 'Directional Solidification'. A further advance of this technique is to make the blade out of a single crystal. Each method extends the useful creep life of the blade (fig. 5-13) and in the case of the single crystal blade, the operating temperature can be substantially increased.

A non-metal-based turbine blade can be manufactured from reinforced ceramics. Their initial production application is likely to be for small high speed turbines which have very high turbine entry temperatures. An example of a ceramic blade is shown in fig. 5-14.

Balancing of a turbine

The balancing of a turbine is an extremely important operation in its assembly. In view of the high rotational speeds and the mass of materials, any unbalance could seriously affect the rotating assembly bearings and engine operation. Balancing is effected on a special balancing machine.