Compressor-Turbine Matching

The flow characteristics of the turbine must be very carefully matched with those of the compressor to obtain the maximum efficiency and performance of the engine. If, for example, the nozzle guide vanes allowed too low a maximum flow, then a back pressure would build up causing the compressor to surge ; too high a flow would cause the compressor to choke. In either condition a loss of efficiency would very rapidly occur.

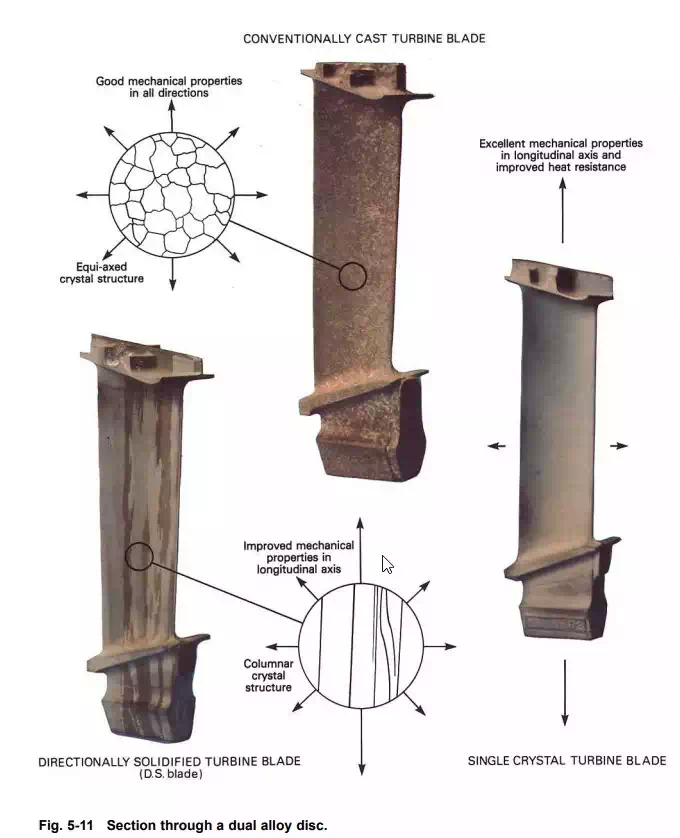

Materials

Among the obstacles in the way of using higher turbine entry temperatures have always been the effects of these temperatures on the nozzle guide vanes and turbine blades, The high speed of rotation which imparts tensile stress to the turbine disc and blades is also a limiting factor.

Nozzle guide vanes

Due to their static condition. the nozzle guide vanes do not endure the same rotational stresses as the turbine blades. Therefore, heat resistance is the property most required. Nickel alloys are used, although cooling is required to prevent melting. Ceramic coatings can enhance the heat resisting properties and, for the same set of conditions, reduce the amount of cooling air required, thus improving engine efficiency.

Turbine discs

A turbine disc has to rotate at high speed in a relatively cool environment and is subjected to large rotational stresses. The limiting factor which affects the useful disc life is its resistance to fatigue cracking.

In the past, turbine discs have been made in ferritic and austenitic steels but nickel based alloys are currently used. Increasing the alloying elements in nickel extend the life limits of a disc by increasing fatigue resistance. Alternatively, expensive powder metallurgy discs, which offer an additional 10% in strength, allow faster rotational speeds to be achieved.