Combustion Chamber Performance

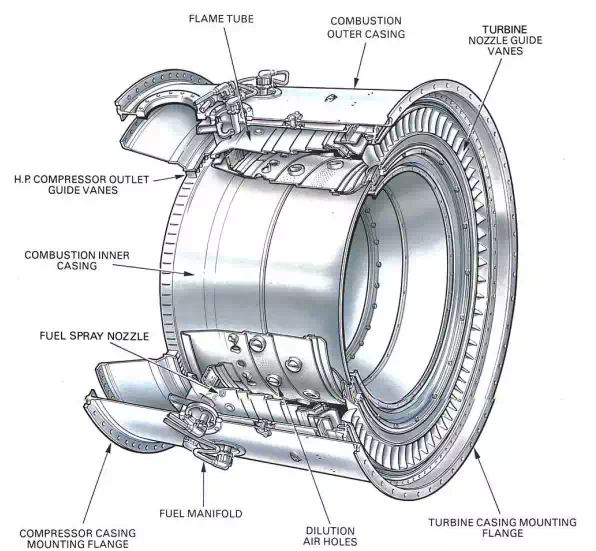

A combustion chamber must be capable of allowing fuel to burn efficiently over a wide range of operating conditions without incurring a large pressure loss. In addition, if flame extinction occurs, then it must be possible to relight. In performing these functions, the flame tube and spray nozzle atomizer components must be mechanically reliable.

The gas turbine engine operates on a constant pressure cycle, therefore any loss of pressure during the process of combustion must be kept to a minimum. In providing adequate turbulence and mixing, a total pressure loss varying from about 3 to 8 per cent of the air pressure at entry to the chamber is incurred.

Combustion intensity

The heat released by a combustion chamber or any other heat generating unit is dependent on the volume of the combustion area. Thus, to obtain the required high power output, a comparatively small and compact gas turbine combustion chamber must release heat at exceptionally high rates.

For example, at take-off conditions a RollsRoyce RB211-524 engine will consume 20,635 lb. of fuel per hour. The fuel has a calorific value of approximately 18,550 British thermal units per lb., therefore the combustion chamber releases nearly 106,300 British thermal units per second. Expressed in another way this is an expenditure of potential heat at a rate equivalent to approximately 150,000 horsepower. Combustion efficiency

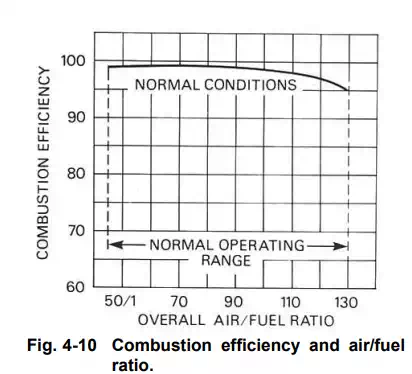

The combustion efficiency of most gas turbine engines at sea-level take-off conditions is almost 100 per cent, reducing to 98 per cent at altitude cruise conditions, as shown in fig. 4-10.

Combustion stability

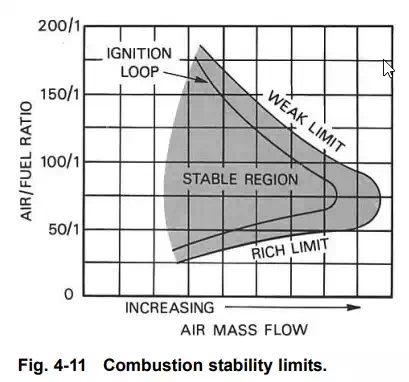

Combustion stability means smooth burning and the ability of the flame to remain alight over a wide operating range.

For any particular type of combustion chamber there is both a rich and weak limit to the air/fuel ratio, beyond which the flame is extinguished. An extinction is most likely to occur in flight during a glide or dive with the engine idling, when there is a high airflow and only a small fuel flow, i.e. a very weak mixture strength.

The range of air/fuel ratio between the rich and weak limits is reduced with an increase of air velocity, and if the air mass flow is increased beyond a certain value, flame extinction occurs. A typical stability loop is illustrated in fig. 4-11. The operating range defined by the stability loop must obviously cover the air/fuel ratios and mass flow of the combustion chamber.

The ignition process has weak and rich limits similar to those shown for stability in fig. 4-11. The ignition loop, however, lies within the stability loop since it is more difficult to establish combustion under 'cold' conditions than to maintain normal burning. Emissions

The unwanted pollutants which are found in the exhaust gases are created within the combustion chamber. There are four main pollutants which are legislatively controlled; unburnt hydrocarbons (unburnt fuel), smoke (carbon particles), carbon monoxide and oxides of nitrogen. The principal conditions which affect the formation of pollutants are pressure, temperature and time.

In the fuel rich regions of the primary zone, the hydrocarbons are converted into carbon monoxide and smoke, Fresh dilution air can be used to oxidize the carbon monoxide and smoke into non-toxic carbon dioxide within the dilution zone. Unburnt hydrocarbons can also be reduced in this zone by continuing the combustion process to ensure complete combustion.

Oxides of nitrogen are formed under the same conditions as those required for the suppression of the other pollutants, Therefore it is desirable to cool the flame as quickly as possible and to reduce the time available for combustion. This conflict of conditions requires a compromise to be made, but continuing improvements in combustor design and performance has led to a substantially 'cleaner' combustion process.

Materials

The containing walls and internal parts of the combustion chamber must be capable of resisting the very high gas temperature in the primary zone. In practice, this is achieved by using the best heatresisting materials available, the use of high heat resistant coatings and by cooling the inner wall of the flame tube as an insulation from the flame.

The combustion chamber must also withstand corrosion due to the products of the combustion, creep failure due to temperature gradients and fatigue due to vibrational stresses.