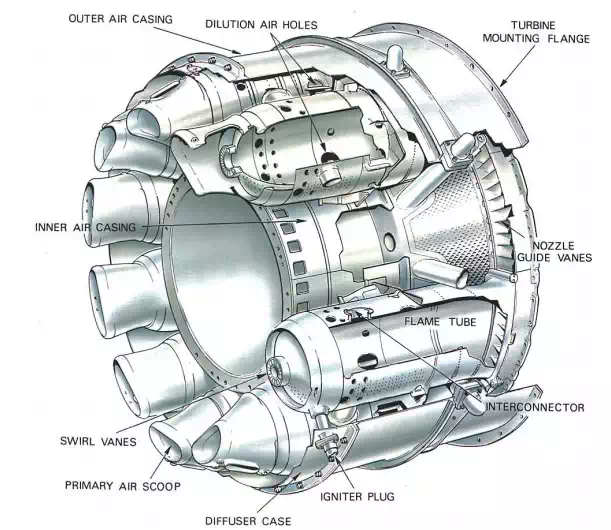

Annular combustion chamber

This type of combustion chamber consists of a single flame tube, completely annular in form, which is contained in an inner and outer casing (fig. 4-9). The airflow through the flame tube is similar to that already described, the chamber being open at the front to the compressor and at the rear to the turbine nozzles.

The main advantage of the annular chamber is that, for the same power output, the length of the chamber is only 75 per cent of that of a tubo-annular system of the same diameter, resulting in considerable saving of weight and production cost. Another advantage is the elimination of combustion propagation problems from chamber to chamber.

In comparison with a tubo-annular combustion system, the wall area of a comparable annular chamber is much less; consequently the amount of cooling air required to prevent the burning of the flame tube wall is less, by approximately 15 per cent, This reduction in cooling air raises the combustion efficiency (para. 27) to virtually eliminate unburnt fuel, and oxidizes the carbon monoxide to non-toxic carbon dioxide, thus reducing air pollution.

The introduction of the air spray type fuel spray nozzle (Part 10) to this type of combustion chamber

Fig. 4-8 Tubo-annular combustion chamber.

also, greatly improves the preparation of fuel for combustion by aerating the over-rich pockets of fuel vapours close to the spray nozzle; this results in a large reduction in initial carbon formation.