Types of Combustion Chamber

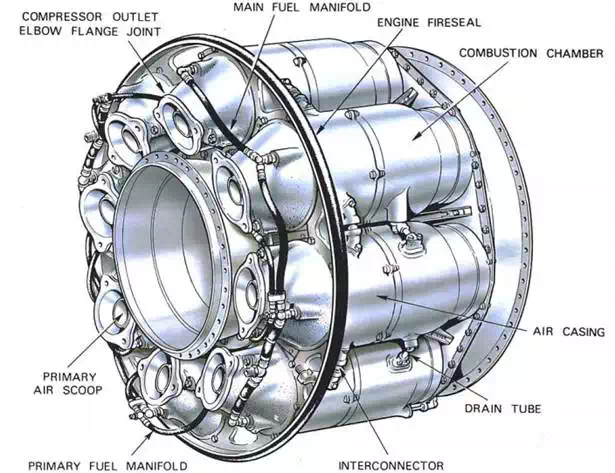

There are three main types of combustion chamber in use for gas turbine engines. These are the multiple chamber, the tubo-annular chamber and the annular chamber. Multiple combustion chamber.

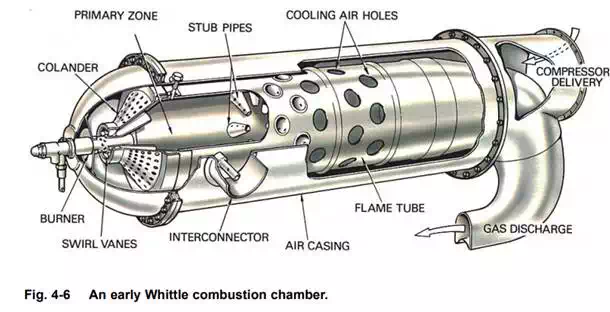

This type of combustion chamber is used on centrifugal compressor engines and the earlier types of axial flow compressor engines. It is a direct development of the early type of Whittle combustion chamber. The major difference is that the Whittle chamber had a reverse flow as illustrated in fig. 4-6 but, as this created a considerable pressure loss, the straight-through multiple chamber was developed by Joseph Lucas Limited.

The chambers are disposed around the engine (fig. 4-7) and compressor delivery air is directed by ducts to pass into the individual chambers. Each

chamber has an inner flame tube around which there is an air casing. The air passes through the flame tube snout and also between the tube and the outer casing.

The separate flame tubes are all interconnected. This allows each tube to operate at the same pressure and also allows combustion to propagate around the flame tubes during engine starting.

Fig. 4-7 Multiple combustion chambers.

Tubo-annular combustion chamber

The tubo-annular combustion chamber bridges the evolutionary gap between the multiple and annular types. A number of flame tubes are fitted inside a common air casing (fig. 4-8). The airflow is similar to that already described. This arrangement combines the ease of overhaul and testing of the multiple system with the compactness of the annular system.