Operating principles of Compressors

During operation the rotor is turned at high speed by the turbine so that air is continuously induced into the compressor, which is then accelerated by the rotating blades and swept rearwards onto the adjacent row of stator vanes. The pressure rise results from the energy imparted to the air in the rotor which increases the air velocity. The air is then decelerated (diffused) in the following

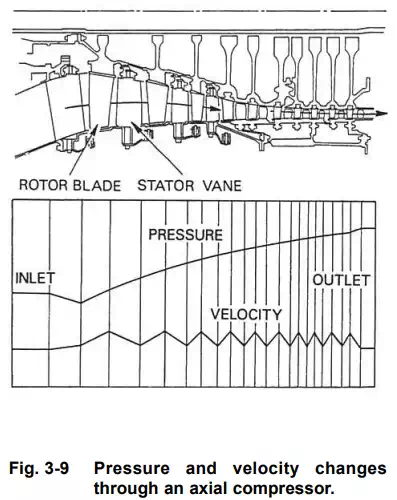

stator passage and the kinetic energy translated into pressure. Stator vanes also serve to correct the deflection given to the air by the rotor blades and to present the air at the correct angle to the next stage of rotor blades. The last row of stator vanes usually act as air straighteners to remove swirl from the air prior to entry into the combustion system at a reasonably uniform axial velocity. Changes in pressure and velocity that occur in the airflow through the compressor are shown diagrammatically in fig. 3-9. The changes are accompanied by a progressive increase in air temperature as the pressure increases.

Across each stage the ratio of total pressures of outgoing air and inlet air is quite small, being between 1:1 and 1:2. The reason for the small pressure increase through each stage is that the rate of diffusion and the deflection angle of the .blades must be limited if losses due to air breakaway at the blades and subsequent blade stall are to be avoided. Although the pressure ratio of each stage is small, every stage increases the exit pressure of the stage that precedes it. So whilst this first stage of a compressor may only increase the pressure by 3 to 4 lb. per sq. in., at the rear of a thirty to one compression system the stage pressure rise can be up to 80 lb, per sq. in, The ability to design multistage axial compressors with controlled air velocities and straight through flow, minimizes losses and results in a high efficiency and hence low fuel consumption. This gives it a further advantage over the centrifugal compressor where these conditions are fundamentally not so easily achieved.

The more the pressure ratio of a compressor is increased the more difficult it becomes to ensure that it will operate efficiently over the full speed range. This is because the requirement for the ratio of inlet area to exit area, at the high speed case, results in an inlet area that becomes progressively too large relative to the exit area as the compressor speed and hence pressure ratio is reduced. The axial velocity of the inlet air in the front stages thus becomes low relative to the blade speed, this changes the incidence of the air onto the blades and a condition is reached where the flow separates and the compressor flow breaks down. Where high pressure ratios are required from a single compressor this problem can be overcome by introducing variable stator vanes in the front stages of the system. This corrects the incidence of air onto the rotor blades to angles which they can tolerate. An alternative is the incorporation of interstage bleeds, where a proportion of air after entering the compressor is Compressors removed at an intermediate stage and dumped into the bypass flow. While this method corrects the axial velocity through the preceding stages, energy is wasted and incorporation of variable stators is preferred.

The fan of the high by-pass ratio turbo-fan is an example of an axial compressor which has been optimized to meet the specific requirements of this cycle. While similar in principle to the core compressor stage, the proportions of design are such that the inner gas path is similar to that of the core compressor that follows it, while the tip diameter is considerably larger. The mass flow passed by the fan is typically six times that required by the core, the remaining five sixths by-pass the core and is expanded through its own coaxial nozzle or may be mixed with the flow at exit from the core in a common nozzle. To optimize the cycle the by-pass flow has to be raised to a pressure of approximately 1.6 times the inlet pressure. This is achieved in the fan by utilizing very high tip speeds (1500 ft. per sec.) and airflow such that the by-pass section of the blades operate with a supersonic inlet air velocity of up to Mach 1.5 at the tip. The pressure that results is graded from a high value at the tip where relative velocities are highest to the more normal values of 1.3 to 1.4 at the inner radius which supercharges the core where aerodynamic design is more akin to that of a conventional compressor stage. The capability of this type of compressor stage achieves the cycle requirement of high flow per unit of frontal area, high efficiency and high-pressure ratio in a single rotating blade row without inlet guide vanes within an acceptable engine diameter. Thus keeping weight and mechanical complexity at an acceptable level.

Construction

The construction of the compressor centres around the rotor assembly and casings. The rotor shaft is supported in ball and roller bearings and coupled to the turbine shaft in a manner that allows for any slight variation of alignment. The cylindrical casing assembly may consist of a number of cylindrical casings with a bolted axial joint between each stage or the casing may be in two halves with a bolted centre line joint. One or other of these construction methods is required in order that the casing can be assembled around the rotor.