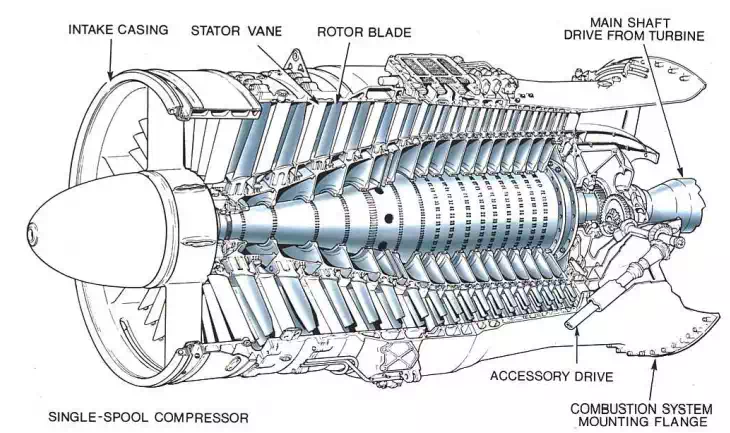

The Axial Flow Compressor

An axial flow compressor (fig. 3-7 and fig. 3-8) consists of one or more rotor assemblies that carry blades of airfoil section. These assemblies are mounted between bearings in the casings which incorporate the stator vanes. The compressor is a multi-stage unit as the amount of pressure increase by each stage is small; a stage consists of a row of rotating blades followed by a row of stator vanes. Where several stages of compression operate in series on one shaft it becomes necessary to vary the stator vane angle to enable the compressor to operate effectively at speeds below the design condition. As the pressure ratio is increased the incorporation of variable stator vanes ensures that the airflow is directed onto the succeeding stage of rotor blades at an acceptable angle, ref. para. 30, Airflow Control.

From the front to the rear of the compressor, i.e. from the low to the high pressure end, there is a gradual reduction of the air annulus area between the rotor shaft and the stator casing. This is necessary to maintain a near constant air axial velocity as the density increases through the length of the compressor. The convergence of the air annulus is achieved by the tapering of the casing or rotor. A combination of both is also possible, with the arrangement being influenced by manufacturing problems and other mechanical design factors.

A single-spool compressor (fig. 3-7) consists of one rotor assembly and stators with as many stages as necessary to achieve the desired pressure ratio and all the airflow from the intake passes through the compressor.

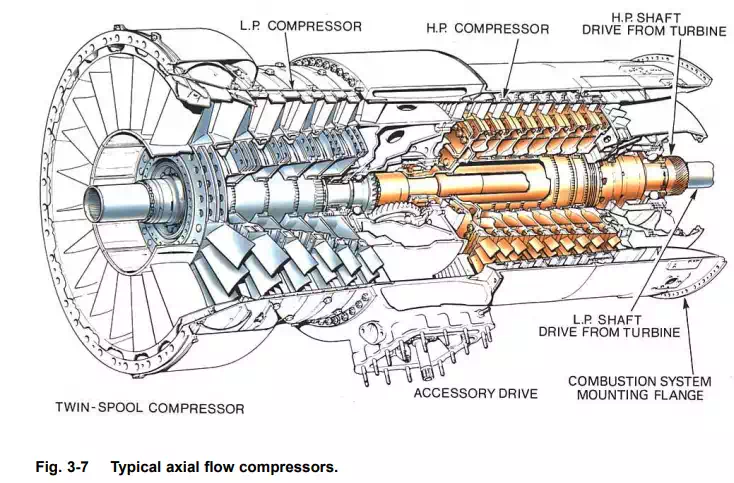

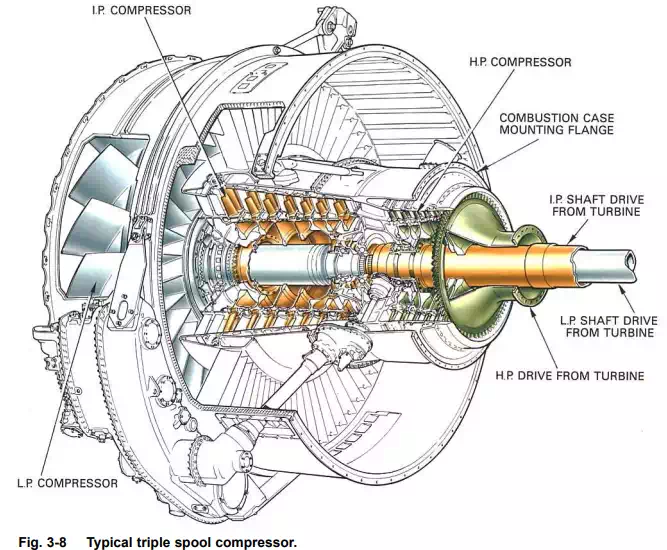

The multi-spool compressor consists of two or more rotor assemblies, each driven by their own turbine at an optimum speed to achieve higher pressure ratios and to give greater operating flexibility.

Although a twin-spool compressor (fig. 3-7) can be used for a pure jet engine, it is most suitable for the by-pass type of engine where the front or low pressure compressor is designed to handle a larger airflow than the high pressure compressor. Only a percentage of the air from the low pressure compressor passes into the high pressure compressor; the remainder of the air, the by-pass flow, is ducted around the high pressure compressor. Both flows mix in the exhaust system before passing to the propelling nozzle. This arrangement matches the velocity of the jet nearer to the optimum requirements of the aircraft and results in higher propulsive efficiency, hence lower fuel consumption. For this reason the pure jet engine where all the airflow passes through the full compression cycle is now obsolete for all but the highest speed aircraft.

With the high by-pass ratio turbo-fan this trend is taken a stage further. The intake air undergoes only one stage of compression in the fan before being split between the core or gas generator system and the by-pass duct in the ratio of approximately one to five (fig. 3-8). This results in the optimum arrangement for passenger and/or transport aircraft flying at just below the speed of sound. The fan may be coupled to the front of a number of core compression stages (two shaft engine) or a separate shaft driven by its own turbine (three shaft engine).