Pressure Drag

WHY IS

PRESSURE SUCH A DRAG?

Air

flowing past an object pushes harder against the front than the back. This

difference creates a backward force called pressure drag.

DOES DRAG

INCREASE WITH SPEED?

As

an aircraft's speed increases, drag on the aircraft generally increases much

faster. Doubling the speed makes the airplane encounter twice as much air

moving twice as fast, causing drag to quadruple. Drag, therefore, sets

practical limits on the speed of an aircraft.

HOW DO YOU

REDUCE PRESSURE DRAG?

The

air pressure against the leading side of an object is higher than the pressure

in the randomly churning eddies of the wake on the other side of it.

Streamlining reduces this pressure difference.

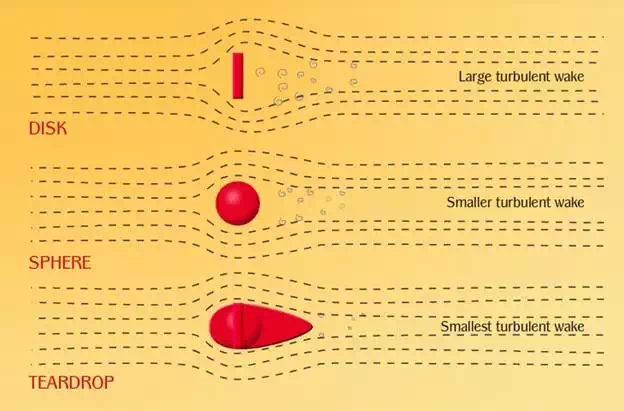

The more

streamlined an object is, the smaller the wake it creates. The area of

turbulent wake behind an object has less pressure than the area in front of the

object, thus a backward force is generated. Although the three shapes above

have the same diameter, the teardrop is more streamlined—it has a rounded front

and tapered tail, a shape that slips through the air more smoothly and helps

reduce pressure drag.

Even the

wires strung between the upper and lower wings of older biplanes produced

considerable pressure drag. Today aircraft are shaped to minimize drag. The

fuselages of airliners, the supporting struts on aerobatic biplanes, the

enclosures surrounding fixed landing gear, and other exposed surfaces are all

streamlined.

BUT,

keep in mind...

STREAMLINING INCREASES FRICTION DRAG

The more you

streamline an object by elongating its rear surface, the more you reduce the

size of its wake and the resulting pressure drag. But elongating an object

increases its surface area, and that increases the effects of friction—another

form of drag!

Making the

most of streamlining requires a trade-off. An object must be tapered enough to

reduce the size of its wake. But it must also be short enough so the

accompanying increase in friction drag doesn’t offset the lower pressure drag.