Pressure Sensitive Paint

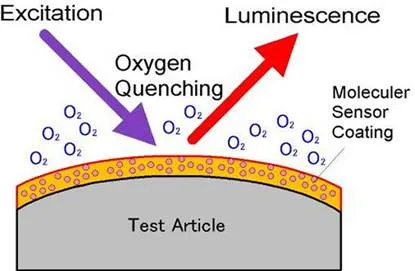

Pressure sensitive paint is an optical method to obtain the pressure on an object surface without instrumenting the object. The surface is coated with a paint containing luminophore molecules(florescent or phosphorescent) and illuminated with light source emitting light of of sufficient short wavelength to excite the luminophore.

The luminophores will emit light of a longer wavelength than the excitation wavelength due to internal transition before excitation. Some luminophores are in addition to normal deactivation through thermal collision also deactivated through collision with oxygen molecules. As the relative contents of oxygen is constant in air the oxygen quenching effect gives an indication of the air pressure above the surface. Hence the lower the pressure, the less emitted light. The theory shows that the pressure is proportional to the inverse of the emitted light intensity.

The technique uses either continuous or pulsating illumination light. In the first method the emitted light intensity is directly measured whereas in the second method either the decay-time or the phase of the emitted light is used. In our experiment the light-source has been continuous.

In practice several effects play part to make the method less simple to use. As stated previously thermal quenching is one, enforcing a strong control of the temperature of the PSP. Others are uneven paint thickness and illumination variations over the surface which make calibration of the entire painted surface necessary.

How PSP is Used?

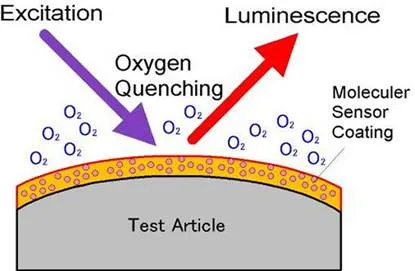

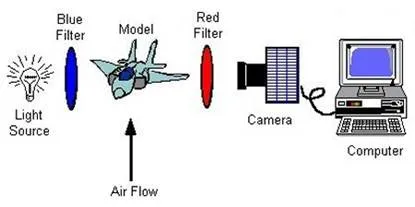

A simple representation of a typical PSP experimental setup is shown above. The model is covered with PSP, which is excited by absorbing light from the light source that has been passed through a blue filter. The light emitted by the PSP is then passed through a red filter and measured by a camera. The camera images are typically redorded by a computer which processes the data to measure the aerodynamic pressures on the model.

Early History:

The phenomena of photoluminescence and oxygen quenching have been studied for many years. Peterson and Fitzgerald were the first to propose the use of these phenomena as a flow visualization tool in 1980. They described an experiment in which a surface was covered with a fluorescent dye that was then excited by a blue light. Once the flow was turned on, either nitrogen or oxygen was injected into the flow through a static pressure tap on the surface.

When nitrogen was injected, a bright streak of luminescence was observed downstream of the tap, due to decreased oxygen quenching. When oxygen was injected, the increased oxygen quenching resulted in a dark streak downstream of the tap. Unfortunately, the PSP used in this experiment was not very conducive to accurate and practical experimental use. The oxygen sensitivity of the dye and the oxygen permeability of the binder were both relatively low. In addition, the PSP layer was thick, rough, and didn't adhere to the surface very well.

Application of PSP:

The first research into PSP as a practical surface pressure field measurement was conducted during the early to mid-1980s in the former Soviet Union at TsAGI/Moscow in cooperation with Moscow University. For a number of years, the efforts of the Soviets in PSP research were not well known in the west, as the information was limited in its distribution. In 1990, the existence of the Soviet PSP technology was revealed to a great extent through an advertisement in Aviation Week & Space Technology magazine. This exposure was the start of a commercialization effort towards the west.

In the United States, the feasibility of using PSP for surface pressure field measurement was demonstrated in 1989 at the NASA Ames Research Center using a coating developed at the University of Washington. Since then, research has continued at NASA Ames, along with programs aimed specifically at aircraft development being conducted at Boeing and McDonnell-Douglas Aerospace (which has since been acquired by Boeing). Other centers of PSP research include the NASA Langley Research Center and the United States Air Force Arnold Engineering and Development Center (AEDC).