Types of composite materials

Composite materials are formed by two or more components so that the properties of the final material are better than the properties of the components separately.

This kind of materials consist of:

· Matrix: sets up the part geometrically, gives cohesion to the material, it is usually flexible and not very resistant and transmits efforts from one fibre to another.

· Reinforcement: provides rigidity and resistance.

Depending on the type of matrix there are:

· Metal matrix composite materials

· Ceramic matrix composite materials

· Organic, polymeric or Reinforced-Plastics matrix composite materials. This group includes composite materials of long fibre reinforcement with a plastic matrix.

Regarding reinforcements, there are different types of them, such as carbon fibres, glass fibres, aramid fibres, natural fibres, etc.

The most used ones because of their lightness and excellent mechanical properties, are composite materials of polymeric matrix with fibre reinforcements. These materials replace others (mainly metallic ones) in those applications in which the mechanical properties-weight relation influences decisively the maintenance costs of the product.

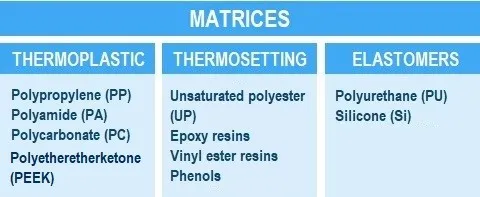

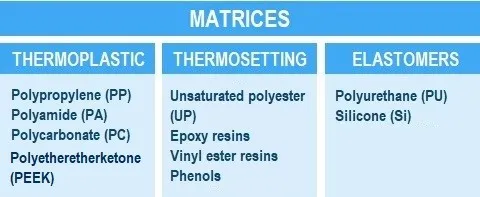

Organic matrices can be thermoplastic, thermosetting or elastomers.

Thermosetting matrices or resins are the most used in high-performance composite materials. These resins result in a solid, insoluble and unmeltable product by a series of chemical reactions known as curing or cross-linking. In contrast, the thermoplastic ones melt when exposed to heat.

The main fibres used as reinforcements are:

· Glass fibres

· Carbon fibres

· Boron fibres

· Ceramic fibres

· Metal fibres

· Aramid fibres

· Natural fibres: sisal, hemp, flax, etc.

Regardless of the type of material they are made of, fibres can appear in form of roving, mats, or fabrics.

Another type of products that are incorporated into the composite material fibre-resin is fillers and additives. They are added with the aim of providing particular characteristics to the material or reducing its cost.

The number of added products varies depending on the properties we want to achieve. The general aim is to improve processability and the finished product.

Structural composite materials can be classified as follows:

· Sandwich structures: composed by a core and layers. They allow to improve the mechanical properties but without an excessive increase of weight. They also improve thermal and acoustic insulation.

· Monolithic structures: parts with a complex geometry, formed by overlapping fabrics with particular orientations that allow obtaining specific characteristics. This kind of parts is intended to withstand the heaviest structural loads.

AIMPLAS has a broad experience in long-fibre composites materials working in different projects to obtain high-added value composites products or to improve the production process.