Strain Hardening

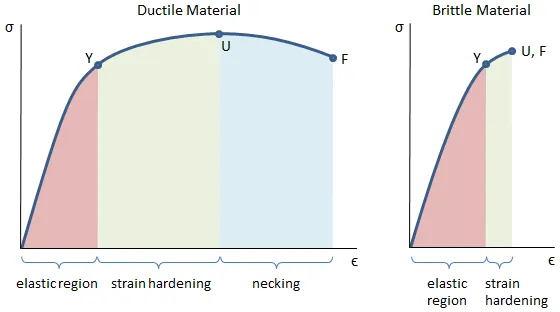

After a material yields, it begins to experience a high rate of plastic deformation. Once the material yields, it begins to strain harden which increases the strength of the material. In the stress-strain curves below, the strength of the material can be seen to increase between the yield point Y and the ultimate strength at point U. This increase in strength is the result of strain hardening.

The ductile material in the figure below is still able to support load even after the ultimate strength is reached. However, after the ultimate strength at point U, the increase in strength due to strain hardening is outpaced by the reduction in load-carrying ability due to the decrease in cross sectional area. Between the ultimate strength at point U and the fracture point F, the engineering strength of the material decreases and necking occurs.

In the stress-strain curve for the brittle material below, a very small region of strain hardening is shown between the yield point Y and the ultimate strength U. Note however that a brittle material may not actually exhibit any yielding behavior or strain hardening at all -- in this case, the material would fail on the linear portion of the curve. This is more common in materials such as ceramics or concrete.

Because the strain hardening region occurs between the yield point and the ultimate point, the ratio of the ultimate strength to the yield strength is sometimes used as a measure of the degree of strain hardening in a material. This ratio is the strain hardening ratio:

strain hardening ratio = Stu / Sty

According to Dowling, typical values of strain hardening ratio in metals range from approximately 1.2 to 1.4.

If a material is loaded beyond the elastic limit, it will undergo permanent deformation. After unloading the material, the elastic strain will be recovered (return to zero) but the plastic strain will remain.

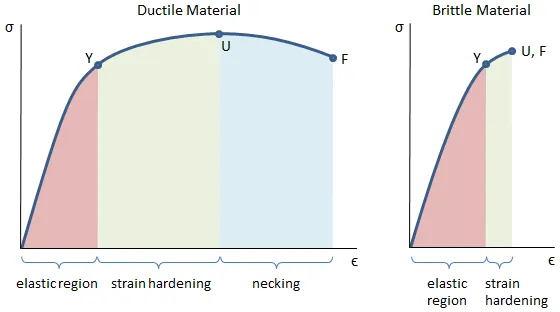

The figure below shows the stress-strain curve of a material that was loaded beyond the yield point, Y. The first time the material was loaded, the stress and strain followed the curve O-Y-Y', and then the load was removed once the stress reached the point Y'. Since the material was loaded beyond the elastic limit, only the elastic portion of the strain is recovered -- there is some permanent strain now in the material. If the material were to be loaded again, it would follow line O'-Y'-F, where O'-Y' is the previous unloading line. The point Y' is the new yield point. Note that the line O'-Y' is linear with a slope equal to the elastic modulus, and the point Y' has a higher stress value than point Y. Therefore, the material now has a higher yield point than it had previously, which is a result of strain hardening that occurred by loading the material beyond the elastic limit.

By strain hardening the material, it now has a larger elastic region and a higher yield stress, but its ductility has been reduced (the strain between points Y'-F is less than the strain between points Y-F).