Difference between linear and nonlinear elastic material

A few years ago I wrote an article about various nonlinear material models. Since I’m a civil engineer to me the obvious dividing line was: linear = no yielding, nonlinear = yielding. But of course, there is far more than that! Today let’s take a look at a nonlinear elastic material.

Both linear and nonlinear elastic materials will elastically return to an “unloaded” state after loading (without permanent deformations), but the relationship between stress and strain is different in them. It’s linear for linear elastic material (hence the name) and more complex in a nonlinear case.

I think it’s worth taking a look, because confusing nonlinear elastic material and a plastic material may produce some funky outcomes in some analysis.

Being elastic is actually a super neat feature! Especially since usually high-ductility is praised (i.e. in steel structures), we take elasticity for granted. This is however not always the case, even though each material has at least a very slight elastic portion of the stress-strain curve.

Linear elastic – the “normal” way!

Without a doubt, the simplest approach to elasticity is linear-elasticity. This is a property that means that the relationship between stress and strain in the material is linear. Before a certain strain level, (sometimes small, sometimes pretty big) materials tend to “start” their strain-stress behavior win a linear way. Often, it’s only the question at which strain level materials stop being linearly elastic. When this “limit strain” is reached material will either break, yield (which means it’s not elastic anymore) or it will start behaving in a nonlinear elastic way.

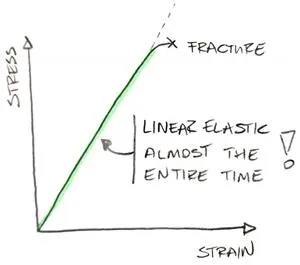

I think that it’s best to discuss linear elasticity on brittle materials (like glass). Then, the stress-strain relation looks like this:

I think it’s reasonable to say that material with such properties can be modeled using linear elastic parameters. OK, there is this small portion near failure that won’t be accurately captured, but I would still be satisfied with the model. Unless of course, this “small portion” won’t be small anymore. But we will discuss that in a second : )

Linear elastic up to a point!

Of course, there are far more material types. Brittle materials are not the only ones you can describe with linear elasticity. However, for the rest, it might be a bit more tricky! I would say that there is a big group of materials (like metals) that are linear elastics “up to a point” and then… they start behaving in a nonlinear way!

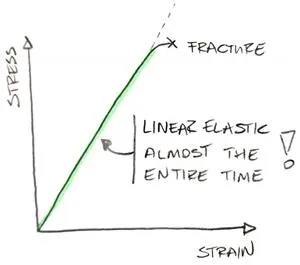

The classical example for me would be the structural steel.

Note that it has a very long linear elastic part. It ends slightly before yielding starts. Of course, it is often assumed that it’s linear elastic up to yielding. To me, it’s accurate “enough”! This means that I use the linear elastic property until the material reaches the yield limit. This is a pretty significant portion of the stress-strain curve. This means that steel is a nice material to model with linear elasticity, as long as you don’t reach strains (and stresses) that would cause yielding. Things start to be more complicated when you actually reach yielding stress…

but I don’t want to go into yielding today. This is a completely different story! No worries though. You can learn plenty about yielding on the blog:

Not linear… but still elastic!

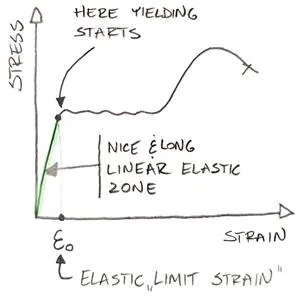

This is a fun category. I would include plastics and foams here. As I mentioned before, steel has a small section “just before yielding” where it’s not linearly elastic anymore. But this “spot” is so small that we can easily ignore it. The similar thing happens with plastics, but there, the zone is so big you just can’t “ignore it”!

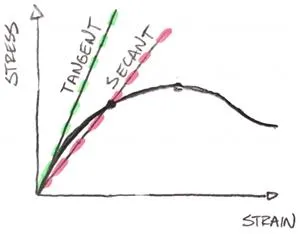

You could argue that in the plastics there is no “linear elastic” part but of course, it’s only the problem of accuracy. After all plastic parts are analyzed using linear elastic parameters as well. It’s clear, that the nonlinear elastic material should be used, but instead, there are two other possibilities: tangent and secant rigidity.

What you do in this case is pretty simple. You can either assume that at the very beginning the material stiffness is “ok”. In such a case you will use the tangent stiffness. However, if you expect that the strains will be high (i.e. close to the start of yielding), then “tangent” stiffness isn’t very accurate. Instead, you could use the secant stiffness. This one is better for higher strains but shows too soft material behavior beforehand.

All in all both approaches aren’t great, but sometimes they may be sufficient. This is the point where actually using nonlinear elastic material model may come in handy. Similarly to steel discussed before, yielding will take place here as well, making the material model pretty interesting… assuming you want to go so far with stresses and strains in your design.

50 shades of nonlinear elastic

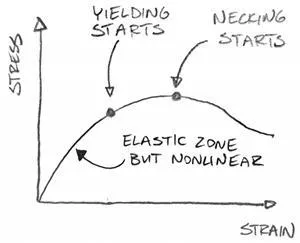

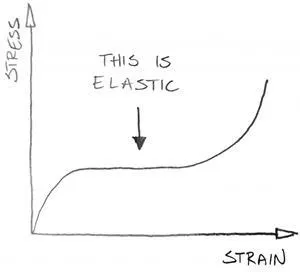

The previous model may look very complex, but that’s not all. There is another material group I want to mention here, and those would be foams. There are more interesting, mostly because certain types of foam never yield. This means that their entire behavior is elastic.

But of course, the behavior is highly nonlinear… otherwise where would be the fun in that, right?

In the above, using tangent or secant stiffness doesn’t look appealing right? I mean sure, if you are somewhere pretty close to the beginning, maybe there is an argument to be made… but it wouldn’t be the best one!

But there is also one additional behavior I want to point out to. Plastics have it as well, but it looks nicer on this chart, so let’s make a small update!

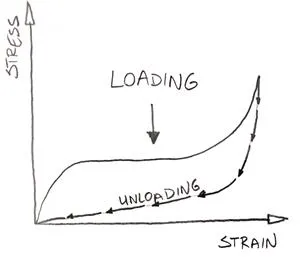

You see, the foam is elastic. It means that when compressed and then released, will return to its original shape without any permanent deformations. But it’s not the same “elastic” as in case of the elastic range for steel element. When the load is taken away from a steel member loaded within the elastic range it behaves differently!

For the steel member, it just gets back following the same stress-strain curve and it happens instantly. Like it would be “eager” to be back in the original shape. Foam is “lazy”. It will slowly get back to the original shape. Not only it doesn’t happen instantly, but it also doesn’t follow the loading stress-strain curve! Such behavior is called viscoelasticity.

You can model it in FEA if you really want to, but it’s rather complex stuff.

Hyperelastic things

If you would want to analyze rubber or maybe elastomers the best way to approach those is with the hyperelastic material.

There are several material models like Mooney-Rivlin, Ogden or Arruda-Boyce.

Sadly I won’t be able to help you out here – this is completely not what I do at my work or have to experience with, and I don’t really want to tell you things I’m not sure about. I promised myself that one day I will take a look at those and learn about them… but there was always something with the higher priority on my to-learn list.

If I ever learn more, I will be more than happy to get back here and add something interesting : )

If you happen to have practical experience with those materials let me know – I will gladly host you on the blog!