Auto pilot System

An autopilot is a mechanical, electrical, or hydraulic system used to guide a vehicle without assistance from a human being. An autopilot can refer specifically to aircraft, self-steering gear for boats, or auto guidance of space craft and missiles. The autopilot of an aircraft is sometimes referred to as “George”, after one of the key contributors to its development.

Today, autopilots are sophisticated systems that perform the same duties as a highly trained pilot. In fact, for some in-flight routines and procedures, autopilots are even better than a pair of human hands. They don’t just make flights smoother -they make them safer and more efficient. We’ll look at how autopilots work by examining their main components, how they work together — and what happens if they fail.

Autopilots and Avionics

In the world of aircraft, the autopilot is more accurately described as the automatic flight control system (AFCS). An AFCS is part of an aircraft’s avionics – the electronic systems, equipment and devices used to control key systems of the plane and its flight. In addition to flight control systems, avionics include electronics for communications, navigation, collision avoidance and weather. The original use of an AFCS was to provide pilot relief during tedious stages of flight, such as high-altitude cruising. Advanced autopilots can do much more, carrying out even highly precise maneuvers, such as landing an aircraft in conditions of zero visibility.

Although there is great diversity in autopilot systems, most can be classified according to the number of parts, or surfaces, they control. To understand this discussion, it helps to be familiar with the three basic control surfaces that affect an airplane’s attitude.

Autopilots can control any or all of these surfaces. A single-axis autopilot manages just one set of controls, usually the ailerons. This simple type of autopilot is known as a “wing leveler” because, by controlling roll, it keeps the aircraft wings on an even keel.

A two-axis autopilot manages elevators and ailerons. Finally, a three-axis autopilot manages all three basic control systems: ailerons, elevators and rudder.

The invention of autopilot

Famous inventor and engineer Elmer Sperry patented the gyrocompass in 1908, but it was his son, Lawrence Burst Sperry, who first flight-tested such a device in an aircraft. The younger Sperry’s autopilot used four gyroscopes to stabilize the airplane and led to many flying firsts, including the first night flight in the history of aviation. In 1932, the Sperry Gyroscope Company developed the automatic pilot that Wiley Post would use in his first solo flight around the world.

Autopilot Parts

The heart of a modern automatic flight control system is a computer with several high-speed processors. To gather the intelligence required to control the plane, the processors communicate with sensors located on the major control surfaces. They can also collect data from other airplane systems and equipment, including gyroscopes, accelerometers, altimeters, compasses and airspeed indicators.

The processors in the AFCS then take the input data and, using complex calculations, compare it to a set of control modes. A control mode is a setting entered by the pilot that defines a specific detail of the flight. For example, there is a control mode that defines how an aircraft’s altitude will be maintained. There are also control modes that maintain airspeed, heading and flight path.

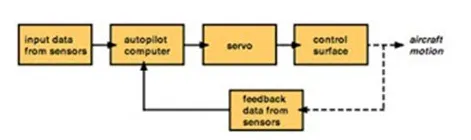

These calculations determine if the plane is obeying the commands set up in the control modes. The processors then send signals to various servomechanism units. A servomechanism, or servo for short, is a device that provides mechanical control at a distance. One servo exists for each control surface included in the autopilot system. The servos take the computer’s instructions and use motors or hydraulics to move the craft’s control surfaces, making sure the plane maintains its proper course and attitude.

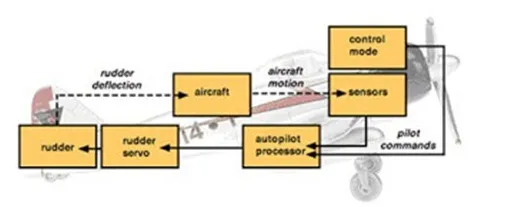

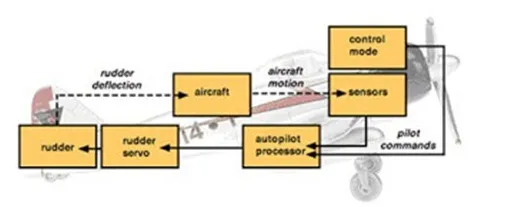

The above illustration shows how the basic elements of an autopilot system are related. For simplicity, only one control surface — the rudder — is shown, although each control surface would have a similar arrangement. Notice that the basic schematic of an autopilot looks like a loop, with sensors sending data to the autopilot computer, which processes the information and transmits signals to the servo, which moves the control surface, which changes the attitude of the plane, which creates a new data set in the sensors, which starts the whole process again. This type of feedback loop is central to the operation of autopilot systems.

Autopilot Control Systems

An autopilot is an example of a control system. Control systems apply an action based on a measurement and almost always have an impact on the value they are measuring. A classic example of a control system is the negative feedback loop that controls the thermostat in your home. Such a loop works like this:

1. Its summertime and a homeowner set his thermostat to a desired room temperature say 78°F.

2. The thermostat measures the air temperature and compares it to the preset value.

3. Over time, the hot air outside the house will elevate the temperature inside the house. When the temperature inside exceeds 78°F, the thermostat sends a signal to the air conditioning unit.

4. The air conditioning unit clicks on and cools the room.

5. When the temperature in the room returns to 78°F, another signal is sent to the air conditioner, which shuts off.

It’s called a negative feedback loop because the result of a certain action (the air conditioning unit clicking on) inhibits further performance of that action. All negative feedback loops require a receptor, a control center and an effector. In the example above, the receptor is the thermometer that measures air temperature. The control center is the processor inside the thermostat. And the effector is the air conditioning unit.

Automated flight control systems work the same way. Let’s consider the example of a pilot who has activated a single-axis autopilot — the so-called wing leveler we mentioned earlier.

1. The pilot sets a control mode to maintain the wings in a level position.

2. However, even in the smoothest air, a wing will eventually dip.

3. Position sensors on the wing detect this deflection and send a signal to the autopilot computer.

4. The autopilot computer processes the input data and determines that the wings are no longer level.

5. The autopilot computer sends a signal to the servos that control the aircraft’s ailerons. The signal is a very specific command telling the servo to make a precise adjustment.

a) Each servo has a small electric motor fitted with a slip clutch that, through a bridle cable, grips the aileron cable. When the cable moves, the control surfaces move accordingly.

b) As the ailerons are adjusted based on the input data, the wings move back toward level.

c) The autopilot computer removes the command when the position sensor on the wing detects that the wings are once again level.

d) The servos cease to apply pressure on the aileron cables.

This loop, shown above in the block diagram, works continuously, many times a second, much more quickly and smoothly than a human pilot could. Two- and three-axis autopilots obey the same principles, employing multiple processors that control multiple surfaces. Some airplanes even have auto thrust computers to control engine thrust. Autopilot and auto thrust systems can work together to perform very complex maneuvers.

Autopilot Failure

Autopilots can and do fail. A common problem is some kind of servo failure, either because of a bad motor or a bad connection. A position sensor can also fail, resulting in a loss of input data to the autopilot computer. Fortunately, autopilots for manned aircraft are designed as a failsafe — that is, no failure in the automatic pilot can prevent effective employment of manual override. To override the autopilot, a crew member simply has to disengage the system, either by flipping a power switch or, if that doesn’t work, by pulling the autopilot circuit breaker.

Some airplane crashes have been blamed on situations where pilots have failed to disengage the automatic flight control system. The pilots end up fighting the settings that the autopilot is administering; unable to figure out why the plane won’t do what they’re asking it to do. This is why flight instruction programs stress practicing for just such a scenario. Pilots must know how to use every feature of an AFCS, but they must also know how to turn it off and fly without it. They also have to adhere to a rigorous maintenance schedule to make sure all sensors and servos are in good working order. Any adjustments or fixes in key systems may require that the autopilot be tweaked. For example, a change made to gyro instruments will require realignment of the settings in the autopilot’s computer.

Modern Autopilot Systems

Many modern autopilots can receive data from a Global Positioning System (GPS) receiver installed on the aircraft. A GPS receiver can determine airplane’s position in space by calculating its distance from three or more satellites in the GPS network. Armed with such positioning information, an autopilot can do more than keep a plane straight and level — it can execute a flight plan.

Most commercial jets have had such capabilities for a while, but even smaller planes are incorporating sophisticated autopilot systems. New Cessna 182s and 206s are leaving the factory with the Garmin G1000 integrated cockpit, which includes a digital electronic autopilot combined with a flight director. The Garmin G1000 delivers essentially all the capabilities and modes of a jet avionics system, bringing true automatic flight control to a new generation of general aviation planes.Wiley Post could have only dreamed of such technology back in 1933.